A Comprehensive Guide to Choosing the Right Industrial Lock

Industrial security is a significant topic. Protecting important machinery, confidential data or restricted areas, industrial locks are the first line of defense, and choosing an appropriate locking mechanism is a key component of overall security and operational integrity.

This guide deciphers the selection process of industrial locks through an overall overview of the types of industrial locks, their application scenarios, and the key considerations to consider when making a choice. When it comes to lock brands, Fornd cannot be overlooked. As a high-end industrial lock manufacturer with 12 years of industry experience, Fornd has become the preferred brand for demanding industrial scenarios with over 1,000 standard and custom locks. Entrust security to Fornd, and enterprises only need to focus on their core business.

What Are the Types of Industrial Locks?

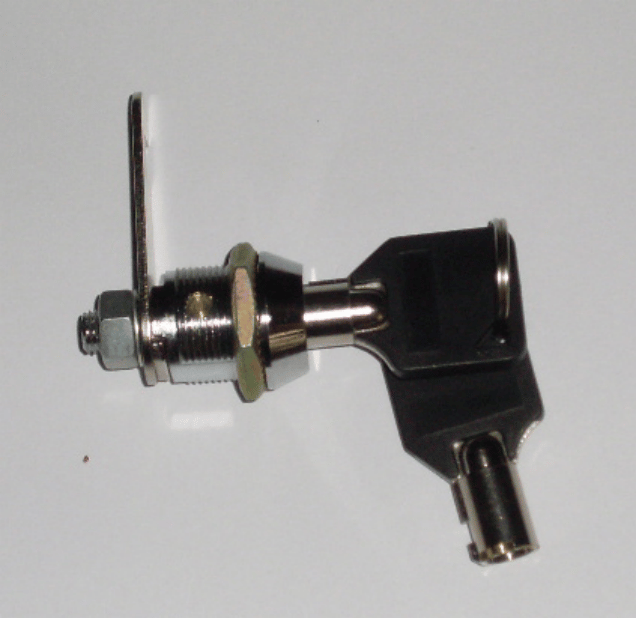

Disc Tumbler Locks

Its core structure consists of a set of usually 3 to 5 rotating discs with special notches at the center and a moving disc meshing with them. When the correct key is inserted, the teeth on the key will rotate each disc, aligning the notches to form a specific "channel", which allows the sliding disc to pass through and drive the lock core to rotate and unlock.

This type of lock is commonly used in padlocks, toolbox locks, cabinet locks, warehouse equipment locks, outdoor electrical box locks and other occasions where durability and environmental adaptability are required to be higher than ultimate security.

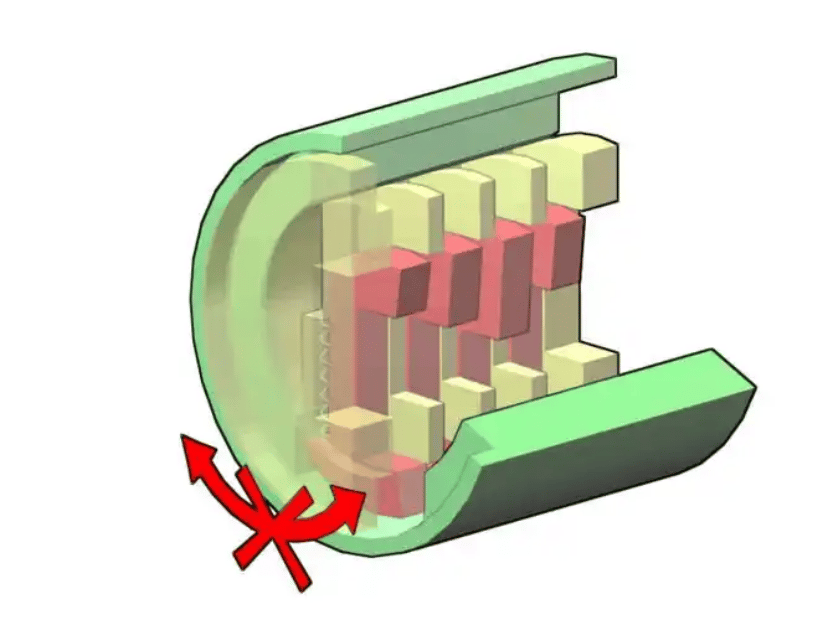

Radial Pin Tumbler (RPT) Locks

This is a structural innovation to the traditional upper and lower pin lock. The pins are not arranged vertically from top to bottom, but are like the spokes of a wheel, radiating (radially) from the periphery of the lock core towards the center. After the key is inserted, the pins in all directions need to be pushed to the correct position simultaneously for the lock core to rotate.

It can be used for access control in high-risk areas, important warehouse doors, data cabinets, precision instrument cabinets, and controlled area access control in the pharmaceutical and chemical industries.

Lever Lock

Inside the lock body of a lever lock, there is a set of levers, usually 2 to 7, with springs, also known as brake plates, and each lever has a notch. When the correct key is inserted, the teeth of the key precisely lift each lever to a specific height, aligning the notches of all levers to form a channel that allows the brake pads of the latch to pass through, thus unlocking.

This type of lock is commonly seen in industrial warehouse doors, vault doors, heavy-duty safety cabinets, archives, prisons, banks and other places that require extremely high physical security levels.

Mechanical Combination Lock

The mechanical combination lock is completely keyless. Inside it, there is a set of precise gear, CAM and brake rod systems. When the knob or dial is rotated and remains on the correct sequence of numbers, the internal components align and the latch is released.

This type of lock can be used in the electrical control cabinets of factory equipment, safety lockers, weapons depots, the gates of areas with restricted access (such as areas only accessible to employees), and facilities that require frequent access by multiple people.

Electronic Combination Lock

An electronic combination lock is composed of an electronic control part (keyboard, control board, motor/electromagnet) and a mechanical execution part (lock body). After the user enters the correct password, the control board will drive the motor or electromagnet to retract the lock tongue and open the door lock.

This type of lock is commonly used in access control at primary and secondary entrances and exits, clean rooms, server rooms, core areas of modern factories, offices, and any other occasions that require flexible and auditable access control.

Radio Frequency Identification (RFID) lock

A type of lock composed of a card reader, control board, electric lock mechanism and authorization certificate (RFID card, key chain or mobile phone NFC). "One-touch open", fast speed, good user experience, no need to take out keys or remember passwords.

Radio frequency identification locks can be used in the core access control systems of large factories and parks, parking lot gates, high-security laboratories, data centers, and any modern industrial facilities that require refined management of permissions by classification and time periods.

The following table helps you understand the specific information of various locks more intuitively:

Lock Type | Core Structure | Main Features | Security Level | Applicable Industrial Products | Advantages | Disadvantages |

Disc Detainer Lock | A set of rotating discs with notches | High durability, dust and water resistance, medium security, keys are easy to duplicate | Medium | Padlocks, cabinet locks, toolboxes, outdoor electrical boxes | Robust structure, suitable for harsh environments | Average resistance to technical opening

|

Radial Pin Tumbler Lock | Pins arranged radially around the lock core | Extremely high resistance to prying and violence, complex keys that are hard to duplicate | High | Important warehouses, data cabinets, high-risk area access control | Top security among traditional locks | Usually higher price |

Lever Lock | A set of lever plates with notches | High physical strength, large key code volume, high reliability | High | Industrial warehouse doors, heavy-duty safes, vault doors | Extremely robust, strong resistance to violent destruction | Larger keys, inconvenient to carry |

Mechanical Combination Lock | Internal gear and cam mechanism | Keyless, shared by multiple people, purely mechanical | Medium-High | Equipment electrical cabinets, secure storage cabinets, restricted areas | No need for electricity, no key management issues | Combination may be observed or leaked |

Electronic Combination Lock | Electronic keypad + control board + electric lock mechanism | Flexible password management, integrable, requires power | High | Main entrances, server rooms, cleanrooms | Convenient management, audit functions | Dependent on electricity, higher cost |

RFID Lock | Card reader + control board + electric lock mechanism | Contactless, extremely flexible management, detailed audit logs | High | Server rooms, cleanrooms, main entrances | Extremely flexible management, detailed audit logs | Dependent on electricity, higher cost |

What Are the Types of Industrial Lock in Fornd?

The following are the specific industrial locks provided by Fornd for your reference: https://fornd.com/category/locks-and-latches-industrial-solutions

Lock Type | Description | Typical Applications |

90° rotation achieves fast locking; key or tool actuated | Electrical panels, ATM enclosures, cabinet doors | |

Pull-down handle compresses and locks in one motion; IP65 sealing available | Outdoor telecom boxes, medical equipment, food machinery | |

Over-center cam delivers high clamping force by hand | Machine guards, transit cases, welding-machine housings | |

Push once to latch, push again to release; clean handle-free look | Network racks, lab instruments, clean-room panels | |

A single actuator drives 2–3 locking points simultaneously; prevents door warpage | Large control cabinets, wind-power converters, railway power boxes | |

Pad-Lockable Hasp Latch | Built-in hasp accepts user’s padlock for extra physical security | Toolboxes, utility cabinets, outdoor EV-charging pedestals |

Heavy-Duty Truck / Container Lock | Investment-cast 304 stainless steel, anti-cut & anti-pry; fits ISO container corners | Shipping containers, mobile battery shelters, military shelters |

How to Choose the Right Industrial Lock for Your Business?

In addition to considering basic security requirements, choosing an appropriate master lock system for industrial facilities also requires careful consideration of multiple factors:

Be clear about the security requirements

Each industrial facility has unique safety requirements depending on the industry, scale and operation mode. Conducting a professional security assessment helps identify vulnerabilities and determine the best locking solution suitable for your specific operations.

Evaluate the types of locks

Choosing the right lock requires understanding its suitability for the environment:

For example, traditional key-operated locks, such as pin locks and cylinder locks, offer reliable security, but they also require strict key control strategies to maintain their effectiveness.

And Fornd has the expertise to manufacture first-class secure industrial cabinet locks. Moreover, the types of locks provided are diverse, ranging from lock cores, compression locks to right-angle rotary locks and so on, all available for your selection. For specific information, you can browse: https://fornd.com/category/locks-and-latches-industrial-solutions

Balance safety and convenience

Although safety is of paramount importance, industrial operations must also ensure that the lock system does not unnecessarily impede work efficiency. For instance, for multi-tenant buildings and office spaces within industrial facilities, the key card access system simplifies the entry process while maintaining security.

Consider environmental factors

Industrial environments pose challenges to the performance and service life of locks.

Due to the possible presence of some corrosive elements in industrial environments, it is required that corrosion-resistant materials be used when manufacturing locks. In addition, extreme temperature conditions, dust and humidity can also affect mechanical and electronic lock components. Fornd also explained to you the necessity of efficient and durable equipment locks: https://fornd.com/post/338

To give a specific example, Fornd offers a series of press-type and compression-type door lock products specifically designed for harsh Marine environments. These products feature high strength, corrosion resistance, high precision and high reliability, and can meet the common challenges and demands in Marine environments.

Why OEMs Choose Fornd as Their Industrial Latch Manufacturer

12+ years of rotary latch manufacturing experience

In-house die-casting, CNC, stamping & coating

ISO-certified production & strict QC (cycle test, load test, salt spray)

Engineering support with drawings & samples

Full OEM/ODM customization for industrial equipment manufacturers

Stable global supply & fast delivery

Wide material and finish options to match different environments

About Fornd

The industrial sector is already extensive. Among various industrial lock brands, Fornd product areas involved in 5 g communication technology, car roof racks, aerospace, Marine ship 12 specific industries such as: https://fornd.com/solution

It is equipped with advanced CNC machining, stamping, zinc and aluminum die-casting, injection molding, MIM and stainless steel casting production lines. These cutting-edge technologies enable Fornd to offer high-quality products that meet the highest standards of quality and reliability. Fornd has been certified by the ISO9001 standard management system and strictly implements it, truly integrating quality and safety into every detail.

If you are looking for a reliable industrial lock brand for your enterprise or project, welcome to visit our official website to learn more product information and obtain a customized solution. We will recommend the most suitable lock configuration for you based on your usage scenarios, security levels and budget requirements.

FAQ

What are the common types of industrial locks?

Common types include disc glass locks, radial pin cup (RPT) locks, lever locks, mechanical combination locks, electronic combination locks and RFID locks, etc.

How to choose the appropriate industrial lock based on the needs of the enterprise?

The safety level, usage scenarios, environmental conditions (such as anti-corrosion, dust-proof and water-proof) and operational convenience should be comprehensively considered.

Why is Fornd's industrial lock recommended?

Fornd locks are structurally robust, humanized in design, and pay attention to details, safety and durability. The most suitable lock configuration can be matched according to the actual usage requirements, security level and budget.

Contact Fornd (Manufacturer)

Upgrade your equipment with durable, precision-engineered latches from a trusted Industrial latch manufacturer.

📩 Email: info@fornd.com

📞 Phone / WhatsApp: +86-19533933853

🌐 Website: https://fornd.com

👉 Request your quote or free sample today.

Fornd — the Industrial lock supplier trusted by global industrial OEMs.