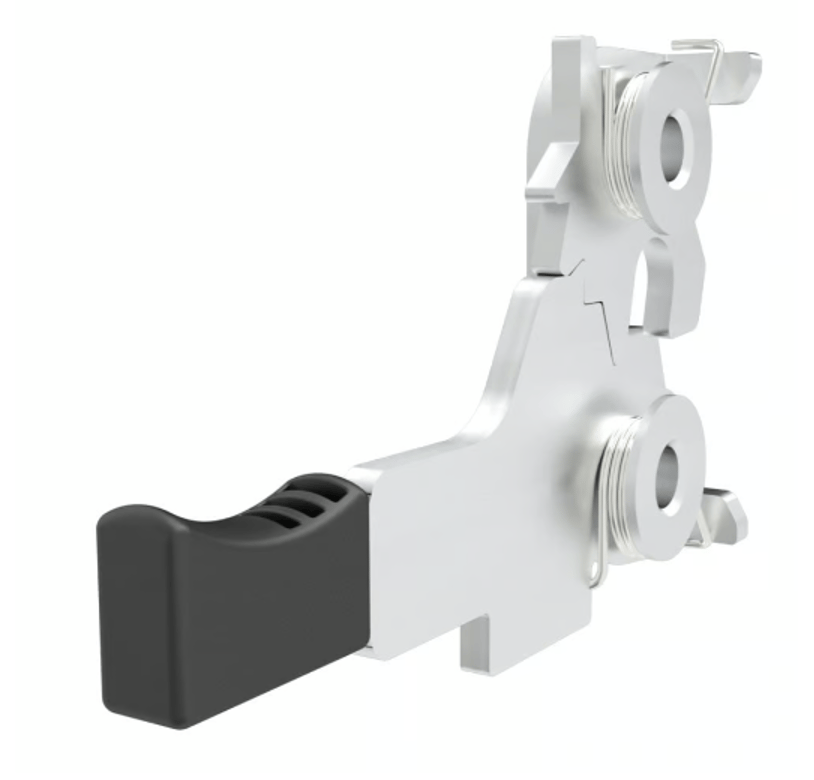

A cabinet latch is designed to keep a cabinet door closed and allows the end user to easily access its interior. It is a fastening device that holds the cabinet door securely fastened to the frame. It typically consists of three main parts: a base, a latch bolt, and a catch. Their design varies to meet specific needs, such as load-bearing capacity, security requirements, and accessibility preferences. To choos the right latch ensures reliable operation, durability, and compatibility with your project’s objectives, Fornd can help you. Fornd is a leading provider of high-quality industrial hinges, specializing in solutions that cater to the demanding needs of various industrial sectors.

Differences between locks and latches

Locks and latches are both devices used to secure doors or gates, but locks focus more on security and typically require a key or code to open, while latches are simpler and can usually be opened manually, offering lower security.

Types of Cabinet Latches

Push Latches

Push latches offer an easy solution for modern cabinets. It is activated by a gentle press. They feature a spring-loaded mechanism that opens the door when pushed and automatically latches when closed. They are made of stainless steel, zinc alloy, nylon and so on. Push latches are applicable to environments such as kitchen cabinets, office storage, or medical equipment.

Toggle Latches

Toggle latches consist of a latch body and a hook or strike plate. They are often reinforced with steel or aluminum to increase strength. Industrial toggle latches feature adjustable tension settings to accommodate doors that weights and vibrations vary.

Magnetic Latches

Magnetic latches close doors by using a magnet and a metal strike plate, which is a smooth and noiseless operation. They are popular in residential settings for their simplicity and clean appearance, but heavy-duty versions with neodymium magnets are used in industrial applications. Magnetic latches' materials include plastic-coated magnets for indoor use and stainless steel for outdoor or wet environments.

Draw Latches

Draw latches are often picked for their appearance. These latches come in two parts, a tab with a small lip to hold the lever arm and the latch itself with a base, a lever, and a lever arm. Draw latches are mounted to the face of the cabinet. Once the lever of these latches is pulled, it detaches the lever arm from the tab and opens the cabinet.

Draw latches are ideal for various purposes. They are more secure and vibration resistant. Moreover, they have a durable life. It is also pretty easy to install and maintain draw latches.

Turn Latches

Turn latches are a classic type of cabinet latches that prove to be great for various designs. These latches come with a catch and a latch body with a turn piece. As the turn latch is used, a bolt loaded by spring slides out of the latch body and goes into the catch, where it stays securely.

Turn latches come in various styles and finishes. They are mounted to the cabinet door’s front and are designed to offer a rustic look. However, they must be latched manually every time you close the cabinet.

On the other hand, butterfly latches are a type of turn latch designed for more heavy-duty usage. They are usually used for shops and RVs and are a more secure and vibration-resistant version of turn latches. The turn pieces of butterfly latches are hinged because they are flush against the surface of the cabinets or doors.

Touch Latches

A touch latch lets you open cabinets without handles, giving them a clean look. It uses a mechanism to keep the door closed, either with a magnet or a spring. To open the door, you just press on it, and the latch releases. With a mechanical latch, a ratchet and spring help the door open when pressed.

Magnetic latches use a magnet to hold the door shut and release when you press it. Installing a touch latch is simple, usually on the back of the door or near the edge, opposite the hinges.

Specialty Latches

Rotary Latches: Used in circular hatches or rotating panels, common in marine applications or aviation.

Bail Latches: Feature a removable bail for padlock integration, ideal for securing valuables in tool chests.

Invisible Edge Latches: Mounted along the door edge for a flush, modern look in high-design cabinets.

Some occasions, especially industrial places, use locks that need to be customized according to the actual situation, Fornd provides customized services.

What are Cabinet Latches Made of ?

Cabinet latches can be made from a variety of materials, including brass, stainless steel, bronze, steel, zinc, and nickel. Different materials have different features. The choice of material depends on the desired durability and longevity of the latch.

Stainless Steel: Best for wet, corrosive environments (kitchens, marine applications) due to rust resistance.

Zinc Alloy: Cost-effective and versatile, suitable for indoor use in residential or light industrial settings.

Brass: Offers corrosion resistance and an elegant finish, ideal for decorative or high-end applications.

Nylon/Plastic: Lightweight and non-magnetic, used in low-load, non-corrosive environments (children’s cabinets, display cases).

Aluminum: Lightweight and durable, suitable for aerospace or portable equipment.

How to Install Cabinet Latches?

Determine the location of the placement. Cabinet latches are installed on the opposite side of the hinge on the cabinet frame. You should try to place the cabinet latch near the cabinet door handle.

Now, put the cabinet latch in the designated location and draw screw holes with a pencil.

Remove the latch and drill the holes into the pencil drawings.

Align the cabinet latch with the screw holes and screw them in.

Close the cabinet door and notice where the latch touches the door. Put a mark in that spot.

Keep the strike place inside the cabinet door and mark the screw holes using a pencil.

Indent the pencil marks using an awl where the strike plate will be installed.

Align the strike plate with the holes and insert the screws into the door.

Now, close the door to test the newly installed latch. You can make slight adjustments by loosening the screws.

How to Mainten

Lubrication: Apply silicone spray to moving parts (e.g., toggle levers, cam mechanisms) to reduce friction and prevent squeaking.

Corrosion Prevention: Wipe down metal latches with a dry cloth in humid environments; apply anti-corrosive coatings for outdoor use.

Regular Inspections: Check for loose screws, worn springs, or misalignment, especially in high-use or heavy-load applications.

Choosing the Right Latch for Your Needs

Load & Usage: Heavy doors require toggle or compression latches; frequent access favors push or magnetic latches.

Environment: Corrosive settings need stainless steel; dry indoor spaces can use zinc alloy or plastic.

Aesthetics: Concealed or magnetic latches for modern looks; slide bolts or toggle latches for industrial ruggedness.

Security: Pair cam or slide bolt latches with padlocks for high-security needs; spring-loaded latches for auto-locking safety.

About Fornd

Fornd, a professional manufacturer of industrial cabinet locks and hardware, provides a wide range of product solutions for industrial applications and offers free samples. Our product line includes-quality electronic locks, hinge handles, and fasteners. Visit the website to learn more: https://fornd.com.