What Is a Compression Latch?

A Compression Latch achieves the locking and unlocking functions by applying force. Normally, when the door is closed, the latch bolt is spring-loaded into the lock body and then it would auto release to engage with the lock hole in the door frame to secure the door. It is one of the locks that has been designed for ease and simplicity of installation and, therefore, is mostly applied to cabinets, drawers, and boxes— applications where quick locking and unlocking is necessary. Besides being easy to operate, it is strong and has a minimal space requirement; therefore, it can be applied in many different areas. Compression Latches are designed with a powerful action mechanism that tightens the door panel, providing shock resistance. They also offer strong sealing capabilities against water and dust, and they can be customized with options for key or tool-secure entry. This makes them versatile door locks that may be used for a variety of purposes.

How Do Compression Latches Work?

A compression latch is a mechanical fastening device that secures two surfaces (e.g., a door and a frame) by applying compressive force when engaged. A tight, vibration-resistant seal is created though its design, best for demanding environments.

· Latch Body: Houses the internal mechanism and mounts to one surface.

· Strike/Keeper: Attached to the opposing surface, it receives and locks the latch.

· Compression Spring: Generates the clamping force when compressed.

· Cam Mechanism: Rotates to engage or disengage the latch.

· Actuator: A lever, handle, or keyed mechanism to operate the latch.

A compression latch operates by having its latch body aligned with a strike as the door or panel is closed. There is then a rotation of an actuator, which in turn causes a cam to pull the strike into the latch body while at the same time compressing a spring. The compression of the spring results in continuous perpendicular force essentially eliminating gaps that may exist, therefore ruling out any possibility of rattling while also providing resistance to vibration. Over-compression adjustments in high-end models are offered to take care of panel misalignment or gasket wear. These latches may, as optional features, compress a gasket for better environmental seal; typically, their sealing is to IP66/67 ratings. Releasing the actuator releases the tension on the spring, and the door/panel is slightly pushed open to give access.

Benefits of Compression Latches

Enhanced Sealing: Compression latches reduce noise in the contraction of the latch as the gaskets and the complete latch mechanism absorb all the noise. This is achievable through proper adjustment and correct utilization.

Vibration Resistance: By providing a firm closure, compression latches reduce noise that may be generated by the movement or friction between components. This proves very significant in applications where noise control is of paramount importance.

Improved Noise Reduction: Due to the consistent pressure of use, the compression latches lead to minimal wear and tear on the components, therefore, they can have extended periods before replacement, especially in demanding conditions.

Enhanced Security: Compression latches, most particularly if they are locking type, would produce a more tight and secure type of fastening which adds more security to the sealing against tampering and unapproved access.

High Versatility: A few compression latches provide adjustable grip range settings where one can adjust and set the grip to make it fit different door thicknesses or gasket sizes. This makes them more versatile and adjustable for different applications.

Choosing the Right Compression Latches

Environment

The environment is a leading consideration in the determination of application requirements for compression latches. It is for outdoor or severe conditions, which include marine, chemicals, or conditions of UV exposure that materials capable of resisting corrosion such as 316 stainless steel or UV-stable polymers would be used. Temperature extremes should also be considered, particularly applications that involve thermal cycling, such as aerospace or automotive under-the-hood applications to ensure material usability at the temperature at which it is expected to operate and to preclude early failure.

Load & Compression Force

Determining the proper clamping force is key to the tight fastening of panels using compression latches. Accurate calculations are needed so as to prevent both over-compression, which can result in damage to the component or deformation of the seal, and under-compression, which leads to inadequate sealing where the panel may become loose. For heavy applications, such as in industrial machines or armored enclosures, the choice of latches having very high spring force ratings between 200 N and 500 N guarantees strong and dependable retaining of the panel.

Adjustability & Tolerance Compensation

Compression latches usually include adjustability features and tolerance compensation to ensure consistent reliable operation. Threaded keepers or strikes allow adjustment to the compression force so that it may take up panel misalignment or gasket thickness variations. The over-center is designed to accommodate automatic latch-up with the over-travel that may occur as materials heat and cool in securing a closure. For the large panels that aircraft doors represent, the clamping from multi-point latches provides a distribution of the clamping forces such that warping is minimized, in addition to a seal that goes all around the periphery of the panel.

Material Selection

Material has a direct effect and is of extreme importance for selecting a compression latch. The choices of material and finish, along with the detailed component design, directly affect product performance and longevity. A good rule of thumb to begin with is - for high corrosion resistance, such as marine, chemical, or food grade, applications use stainless steel, though at a higher cost than other alloys. Zinc die-cast provides an economic solution for general industrial applications. It does have a tendency to corrode in wet applications. For electronic applications, where low weight and capability for EMI shielding are important, some polymer applications can replace the traditional metallic latch. Besides being heavier, they do not have strength. The strength aspect leads to the selection of brass or bronze for decorative finishes or low-spark applications, such as in hazardous areas. These are softer materials as compared to steel.

Compression Latches Offered by Fornd

Fornd is one of the top companies that manufacture compression latches. It has a very wide range of products meant for different types of industrial applications- cam, lever, self-adjusting, and lift & turn latches. These latches are made to offer quick installation and operation, good environmental sealing against dust and water, plus other benefits like vibration and noise reduction, key locking and tool-operated security enhancement, possible flexibility on dimensions to include variation, and gasket compression, and very many more.

Cam Latches

Stainless Steel Hygiene Compression Latches afford cheap simplicity, quick access with a quarter turn, options via many-body materials, and adjustability from modular design with more drive and size choices. The ramp cam makes a cozy fit, lower vibration and rattle.

Cam Latches

Cam Latches

Tooling Locking− secure and resistant to vibrations accomplished by 180° achieved by 5+mm for better sealing and also compression; eccentric to avoid accidental opening. It comes in six body styles for various drives, supports flush mounting, and meets NEMA 4/IP-65. Simple to apply, it requires single-hole installation and has a compact design.

Cam Latches

Cam Latches

Compression Lock for Railways - FORND’s compression latches, built for tough applications in the railway and CNC machining industries, offer fast production cycles with dimensions that can be customized and have strong environmental protection. They provide smooth operation feel with superior mechanical performance that makes them the top choice for CRRC, Alstom, and Bombardier. These latches meet not only the stringent railway vibration and impact standards but also are capable of withstanding 20,000 fatigue cycles, and torsion and load tests.

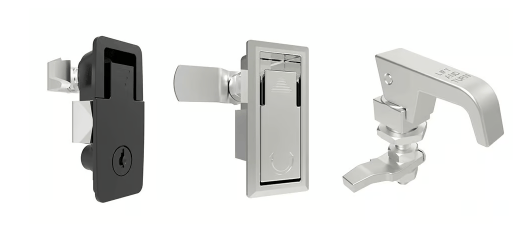

Lever Latches

Lever Latches combine a door lock and handle with an eccentric puller, ensuring secure closure and vibration resistance. Integrated gasket compression minimizes noise. External or hidden rear mounting options cater to various installation needs. The robust design features a long handle for heavy-duty applications, while A2 models offer adjustable retainer locking surfaces and gasket integration.

Lever Latches

Lever Latches

Self Adjusting Latches

Self Adjustable Spring Locks offer a versatile solution with various dimensions and drive types for applications with less stringent pressure requirements. The design would ensure continuous compression upon rotation, enhancing seal integrity. Oblique elastic latches improve closure tightness while toothed elastic versions provide increased vibration resistance. Durable steel latch designs withstand higher impact loads. The three-hole (round hole) mounting pattern accommodates rivet, stud, or welding installation.

Self Adjusting Latches

Self Adjusting Latches

Three-Hole Self Adjustable Compression Latch - simplifies door operation with quick release. It is available in manual and tool-driven versions for both convenience and security. Straight and offset tongues serve different needs for spacing requirements while the user can adjust spacing and compression to aid installation flexibly. Round-hole mounting means strong fastening. Small models give an economical solution for applications needing low compression force and can act as pull-out assists.

Three-Hole Self Adjustable Compression Latch

Three-Hole Self Adjustable Compression Latch

One-Hole Self-Adjustable Compression Latch - The lock tong moves on the threaded lock rod toward the door frame jam, and then it is rotated to adjust compression force. To open, rotate a little, release the compression, and turn the latch to disengage from the door frame. Hand-actuating handles are a textured surface for the handscrew-tool-actuated type, giving more safety for restricted openings. Adjustable user spacing and compression force accommodate varied mounting techniques and configurations. Single hole fixing style speeds installation in holes with set shapes, fast and easy.

One-Hole Self-Adjustable Compression Latch

One-Hole Self-Adjustable Compression Latch

Lift & Turn Latches

Boat Lift & Turn Latches - This latch is made expressly for boats with hatches, doors, or any panels you may have on your boat. Installed to meet style requirements as well as waterproof sealing! It has integrated looks for embedded door locks, simple rotary door locks, and compression door locks with sealing performance.

Lift & Turn Latches

Lift & Turn Latches

Light Lift & Turn Latches - New “lift and turn” compression latch—rapid locking design is enhanced through easy locking configurations. It provides an optimum pull force and prevents, especially, the latch from rubbing and wearing down. Also, there are various surface treatments to suit different installation needs.

Light Lift & Turn Latches

Light Lift & Turn Latches

Heavy Duty Lift & Turn Compression Latches - A strong body, easy use, and steady pulling and pushing make comfortable and simple closing for heavy loads in off-road machines or factory machines. The T-shaped handle gives enough space to hold for people wearing heavy work gloves, and there is hardly any sticking out after folding.

Heavy Duty Lift & Turn Compression Latches

Heavy Duty Lift & Turn Compression Latches

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.