Rotary Latch Systems are robust and versatile locking mechanisms designed to fasten panels, doors, and enclosures securely. Unlike simple latches, they usually use a rotating part that moves into a striker pin, providing a sturdy and strong connection. Most such systems typically comprise three main elements: the rotary latch, an actuator (mechanical or electromechanical), and on some occasions, a cable that joins the two to enable remote operation.

Rotary Latch Systems find wide application in industries such as automotive (for doors, hoods), aerospace (for access panels, cargo doors), and industrial equipment (for enclosures, machine guards). The push-to-close fastener often comes with some degree of security, usually a concealed design and the added benefit of being able to operate it remotely. Owing to their reliable operation under stringent conditions, rotary latches are the first choice for most applications where closures must be robust and durable.

How Does the Rotary Latch System Work?

Rotary Latch System

Rotary Latch System

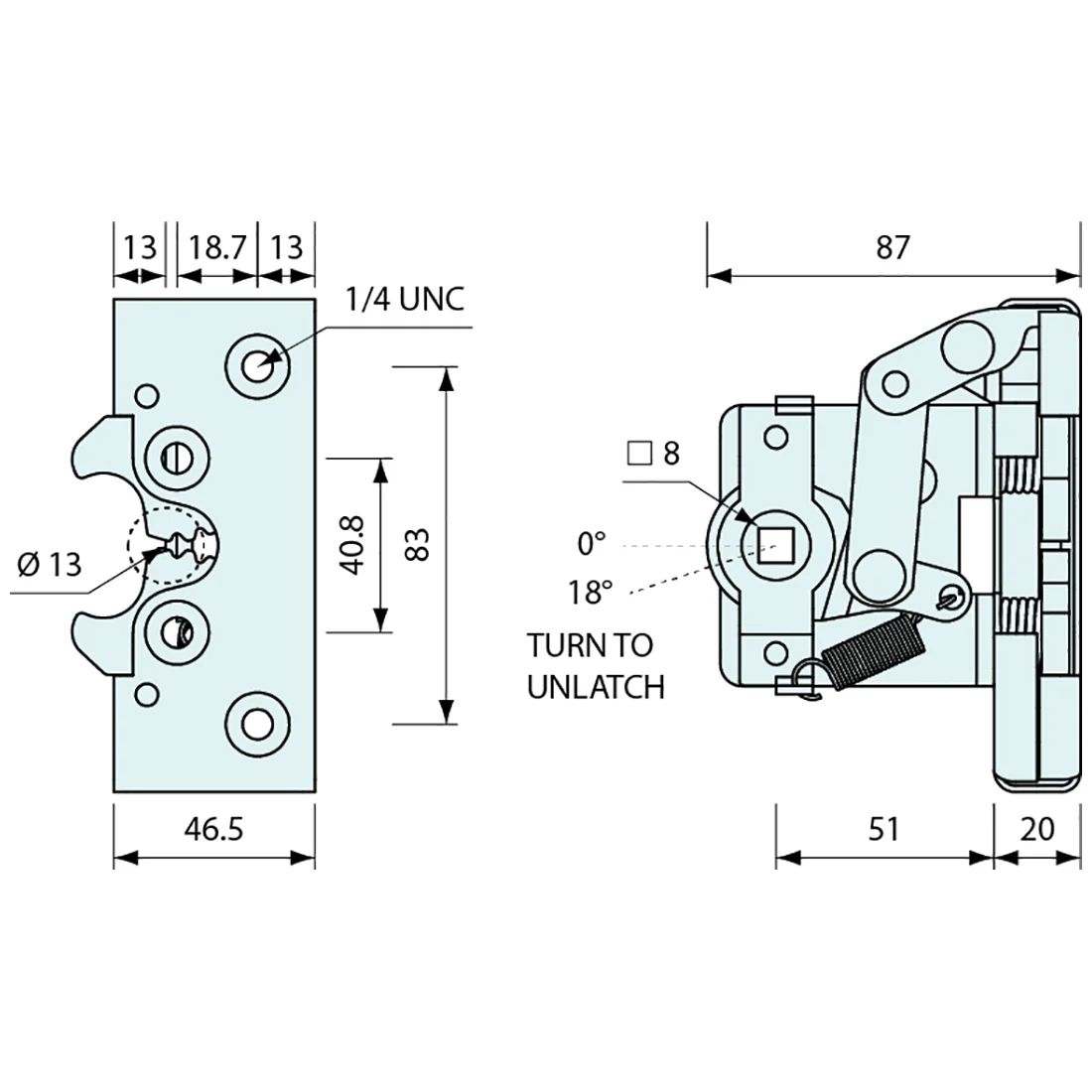

A rotary latch system operates using a simple but effective mechanical principle. The closing lid or door has a striker, mostly a pin or bar, that enters a housing and makes contact with a rotating part of the latch, called the rotary latch. The contact makes the latch rotate, and a strong, small spring-loaded pawl or detent, clicks over past the catch, thereby securing the latch around the striker. The latch remains closed and secure until the pawl is pulled by a lever, handle, or cable: a release mechanism. With the pawl disengaged from the rotary latch, spring force acts to turn the latch back to its opened position, thereby releasing the striker to allow the door to be opened. It is a type extensively used for automobile doors, bonnets, and different kinds of compartments since it ensures reliable security with the least number of moving parts, yet provides some degree of self-adjustment due to wearing on the involved parts for use.

Advantages of Rotary Latch System

Enhanced Security: Rotary latches offer great security through a strong locking feature. The rotary design has a mechanical advantage that allows greater holding force than is possible with the use of non-rotary latches. Two-stage latching is of much value because it gives a quick safety catch and then goes into a fully engaged position to prevent any incomplete closure. This dual position almost cancels the risk of accidental opening due to vibrations in applications where there is a lot of movement, on transit because of impact forces, or where mounting surfaces are not aligned, however, it still offers that provision.

Remote Actuation Capability: Rotary latches are easily integrated with various actuation systems and hence prove to be very flexible in that aspect. It can be used with mechanical actuators - cables, rods, levers, etc.- for manual operation, or with solenoids and electric motors for electronic control. This compatibility allows more advanced implementations such as keyless entry or central locking systems, or emergency release systems. The separation of the latching mechanism from its actuation point allows for the ergonomic placement of release handles and better design freedom.

Hidden and Tamper-Proof Design: After installation, the major parts for latching stay within the assembly, offering great security and look advantages. This hidden feature protects important parts from dirt, debris, and from being tampered with on purpose. With no parts visible to be played with, the latch becomes even more resistant to forced opening. The hidden mechanism also removes any protruding parts that may cause the latch to be caught by some clothes or may even hurt someone, making it suitable for places with a lot of movement or where safety is key.

Push-to-Close Convenience: A spring-loaded rotary mechanism, usually, that allows easy intuitive operation. Just a push of the door or panel, and the striker automatically latches with the latch making an audible as well as a tactile confirmation of the security of the closure. This eliminates self-latching guesswork whether it has properly engaged and effort is required both physically and mentally to manually operate the latch, hence, it increases accessibility, particularly for physically challenged users.

Great Strength and Toughness: Made from top-quality materials like strong steel, steel coated with zinc, or stainless steel that is meant for use in ships, rotary latches offer great ability to bear loads and long life. Many models can hold weights of several thousand pounds or more. Their closed design protects important parts of the environment, and since the force is spread in a circle, there is less wear on one side. These latches usually go through very hard tests for how long they will keep working (sometimes more than 100,000 uses) and stay working in very hot or chemically strong places.

Versatile Application: The adaptability of rotary latches makes them right for many applications across different fields. In cars, they lock doors, hoods, and trunks; at work, they secure panels on heavy machines; in trailers, they lock doors; in AC systems, they lock panels; and in health gear, they lock access points. It can be made small for tech boxes or large and strong for industrial gates and barriers, handling weight from a few pounds up to several tons.

Improved Aesthetics: More than just hiding screws, rotary latches help in making designs look elegant. No surface hardware presents clean, unbroken surface lines that go with the look of modern designs. This inside operation lets flush-mounted panels be used without handles sticking out or visible fastening screws. Without the concern for looks, which usually involves some security, the latches can let designers make the installation look like it belongs with the rest of the structure and look right in the finished product.

Some Tips When Choosing the Right Rotary Latch System

Some Tips When Choosing the Right Rotary Latch System

Some Tips When Choosing the Right Rotary Latch System

Understand Your Application: Clearly define what you're latching, where it's used, and how often it will be operated.

Match Load Requirements: Determine accurately the static and dynamic loads the latch will have to bear, with a safety margin in reserve.

Select the Right Actuation: Choose between remote or direct actuation and the appropriate type of actuator based on your operational needs and user interface.

Address Security Needs: Evaluate the required level of security and consider features like two-stage latching or integrated locking mechanisms.

Consider the Environment: The necessary level of security as spelt out, and features such as two-stage latching or integrated locking mechanisms should be considered.

Respect Size and Weight: Choose a latch that fits within your spatial constraints and meets any weight limitations of your application.

Explore Useful Features: Consider additional functionalities like integrated sensors, anti-rattle mechanisms, or adjustability that could benefit your design.

Factor in Cost and Supplier: Balance your budget with the quality and reliability offered by different suppliers.

Making these decisions doesn’t have to be so overwhelming after all. You’re much better off partnering with a seasoned rotary latch manufacturer such as Fornd rather than trying to go it alone. Well-designed latching systems and access hardware by Fornd will exceed the requirements of your project.

About Fornd

Fornd is a leading Latch Manufacturer and supplier in China. Fornd products include industrial compression latches, rotary latches.

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.