You’ve probably used tubular locks (those “Ace locks” or “circle locks” with round keys) without a second thought—securing your bike, locking a vending machine, or safeguarding a coin-op laundry. They’re everywhere, but here’s what most people miss: how they actually work, what types exist, or how to pick the right one.

As a lock manufacturer focused on demystifying security solutions, Fornd will break it all down for you. Next up: the core mechanics, key types, and simple guides to choosing the perfect tubular lock for your needs.

What Are Tubular Locks?

A tubular lock, also known as a radial or Ace lock, is a pin tumbler lock with a circular keyway and a cylindrical key. It can usually be recognized at a glance by its cylindrical key and ring-shaped lock hole. Its core resembling a computer's power switch.

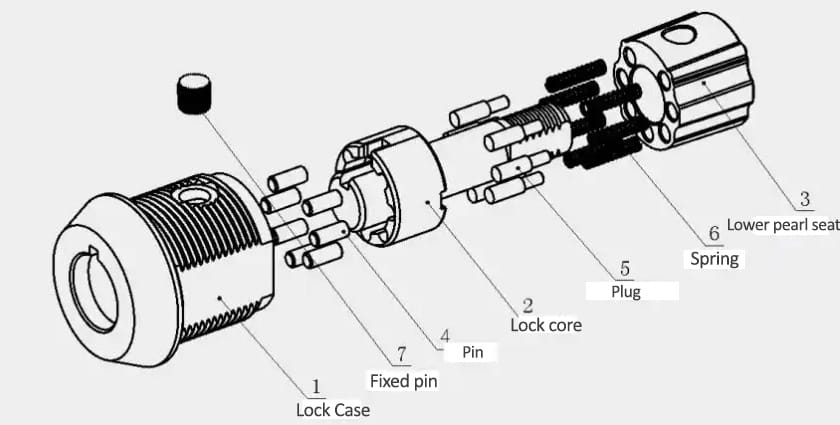

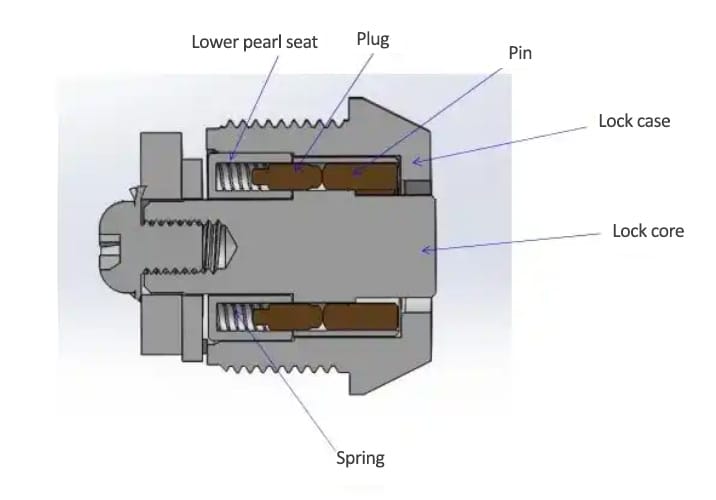

The components of the lock include the lock case, the lock core, the lower pearl seat, the pins, the plug, the spring, and the fixed pin. Unlike traditional flat keys that operate in a linear keyway, tubular keys slide into a circular keyhole and are rotated. The lock's pins are arranged in a circular pattern (radially) around the center of the cylinder, corresponding to the pins set into the circular key.These locks typically contain multiple pins, usually 7 or 8.

How Many Types Do Tubular Locks Have?

There are three types of tubular locks, which are 7-Pin tubular locks, 8-Pin tubular locks and removable core tubular locks.

7-Pin Tubular Locks

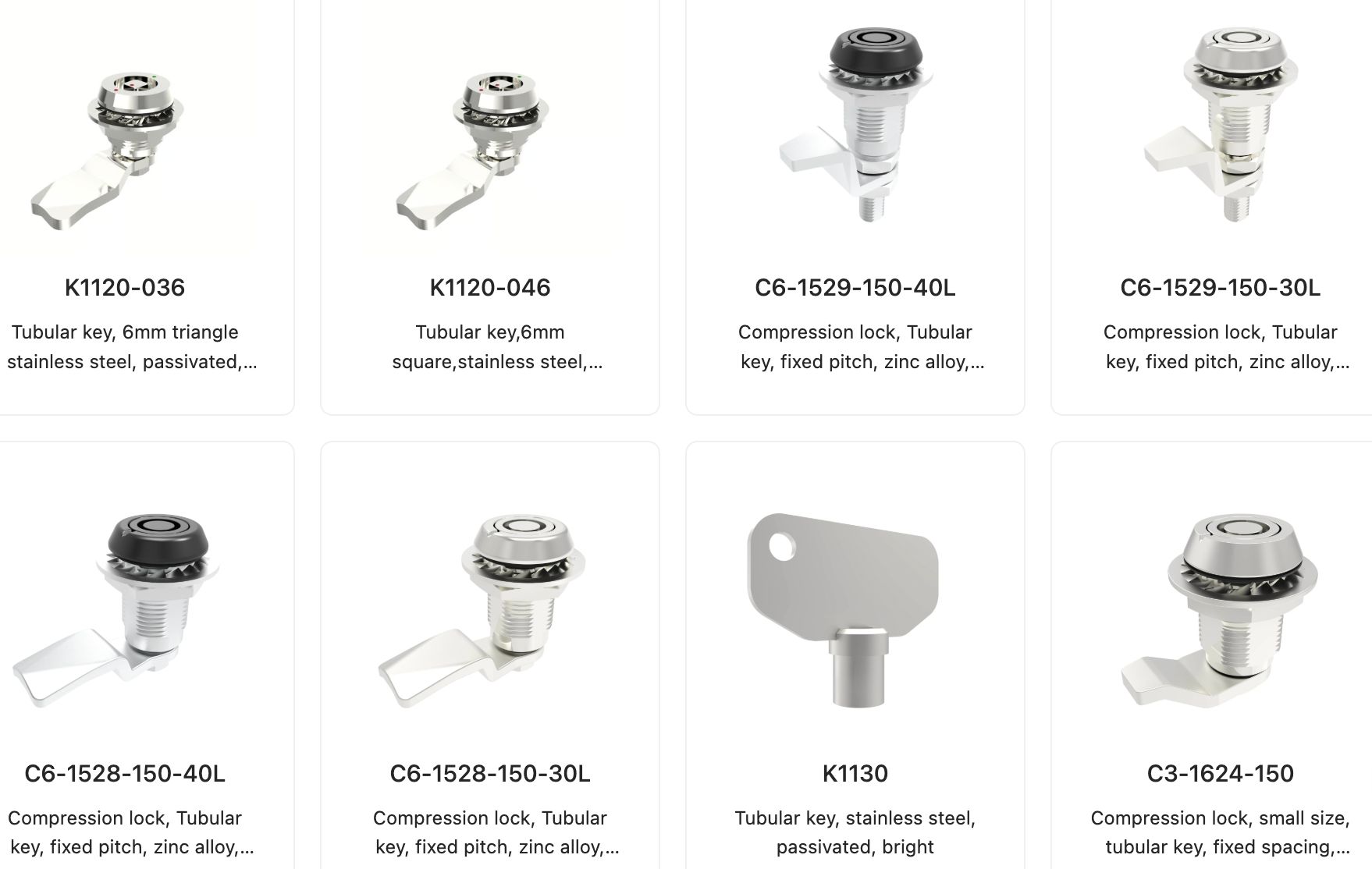

7-Pin tubular locks have 7 pins—enough to create a good number of unique key patterns, making them reliable for general security. You’ll find them in commercial spaces and homes where dependability matters. Examples include models like the K1120-046 (with a 6mm triangular tubular key, stainless steel body, and passivated finish) and the C3-1624-150 (a compact, fixed-pitch stainless steel lock with a passivated key).

8-Pin Tubular Locks

For tighter security, these use 8 pins to generate even more distinct key combinations. They’re a smart pick when you need advanced key uniqueness or extra resistance to picking attempts.

Removable Core Tubular Locks

Popular in commercial settings, these locks let you swap out the entire internal core (the part that does the locking) quickly using a special control key. This makes rekeying large spaces—like offices or banks of vending machines. Like the "Vending machine lock cylinder, tube type, removable, zinc alloy, chrome plating, bright" or the C3-1625-150 (an adjustable-pitch stainless steel lock with a passivated key), both designed for easy maintenance.

Across these types, you’ll find variations in materials (stainless steel, zinc alloy, brass), finishes (chrome-plated, passivated, powder-coated), and key designs (triangular, square, nylon-covered). Common product codes like K1130, B-1105-30-30, or 9200-015 reflect these specs, catering to diverse industrial, commercial, and everyday security needs.

Why choose the Tubular Locks?

Tubular locks are popular for various security applications due to their unique structure and advantages, mainly including:

High security

Tular locks adopt pin tumbler lock structure, with the upper and lower rows of pins distributed in a ring shape, providing strong anti-picking and anti-destruction performance The key is a tubular system with a large number of keys (up to 14,000 combinations), effectively preventing copying and prying.

Wide range of applications

It is suitable for smart terminals, electro-mechanical equipment, cabinets, advertising boxes, fuel dispensers and other scenarios, especially high-frequency opening scenarios (such as vending machines, advertising light boxes). It has a compact size, easy installation, and strong corrosion resistance.

Easy operation

Tubular locks are usually equipped with special tools (such as T-handles), and the unlocking process is quick and efficient. Some models do quick installation, such as vending machine locks, which can be locked by pushing the T-handle.

Customized service

It supports multiple (such as 12.5MM to 38MM operating length), number of pins (7 or 8) and security configurations (such as anti-illing steel balls), which can meet the special needs of different devices.

How Tubular Locks Work?

All locks need to be unlocked and locked, and the pipe lock is no exception. The basic working principle of the two is as follows.

The unlocking principle is that the key is inserted into the lock head, and under the action of the key milling tooth, the bullet is controlled to be flush with the plane of lower pearl seat, and the key drives the lock core to rotate to achieve the purpose of unlocking.

The locking principle is that the spring of the lower pearl seat assembly pushes the pin into the bullet hole of the lock core, limiting the rotation of the lock core to achieve the purpose of locking.

How to Choose the Right Tubular Locks?

You can choose tubular locks according to your own needs. If you're securing bike locks, vending machine cash boxes, or equipment panels where moderate security suffices, you can choose 7-pin tubular locks. If you're securing ATMs, casino cash boxes, medical dispensaries, or sensitive server racks, it is safer to use 8-pin tubular locks. Besides the types of tubular locks, you should also consider materials,physical size and brand. Fornd can meet all of your needs.

About Fornd

Fornd, as a professional tubular lock manufacturer, produces and sells various styles of tubular locks, with 2000 variations of cores, which can be customized to customer requirements, and free samples are sent.

Visit fornd.com to learn more or get a quote for the camper shell locks you require.