Become a Global Distributor of China-made Hinges – Partner with Fornd

Sourcing hinges from several factories is rarely smooth. One supplier talks about fast delivery, another pushes for high MOQ, and the quality can change from one batch to the next. These problems take time and energy—time that could be used to grow sales.

That’s where Fornd steps in. With one certified plant, multiple hinge lines, and proven global distribution, you don’t have to juggle different suppliers anymore. In this guide, we’ll cover what hinges actually are, the main types you’ll run into, where they’re used across industries, and why Fornd has become a trusted partner for distributors worldwide. By the end, you’ll know exactly how to add high-quality China-made hinges to your lineup—and how to do it without the usual headaches.

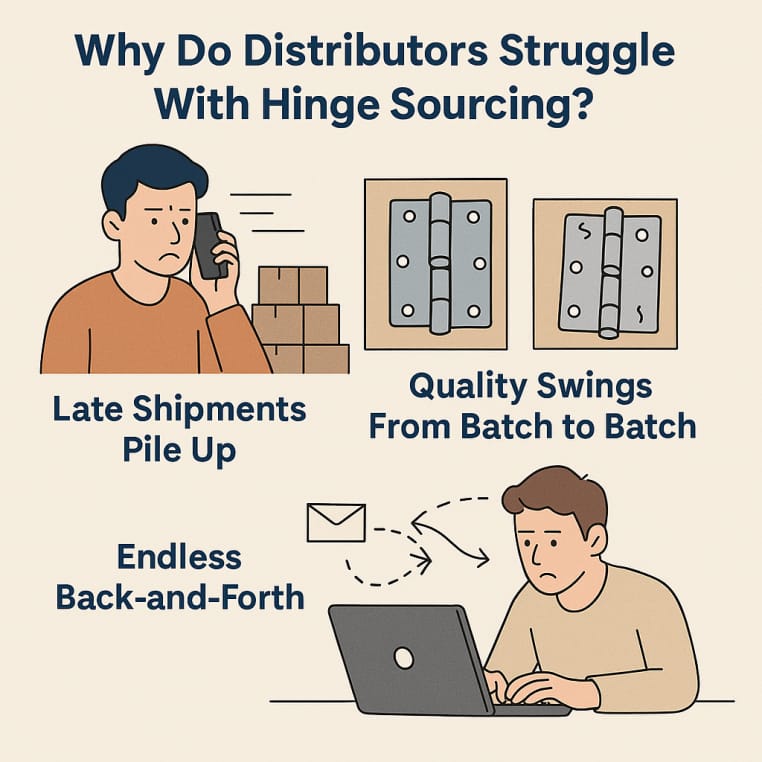

Why Do Distributors Struggle With Hinge Sourcing?

If you’ve ever tried buying hinges from more than one factory, you probably already know the headaches.

Late Shipments

Working with many suppliers often means delays. Deadlines slip, and the customer is the one left waiting.

Quality Variations

One shipment feels solid, the next is loose. Without one clear QC system, results are never certain.

Too Much Back-and-Forth

Every factory has its own rules—MOQ, packaging, lead time. Managing them all creates long email chains and lost time.

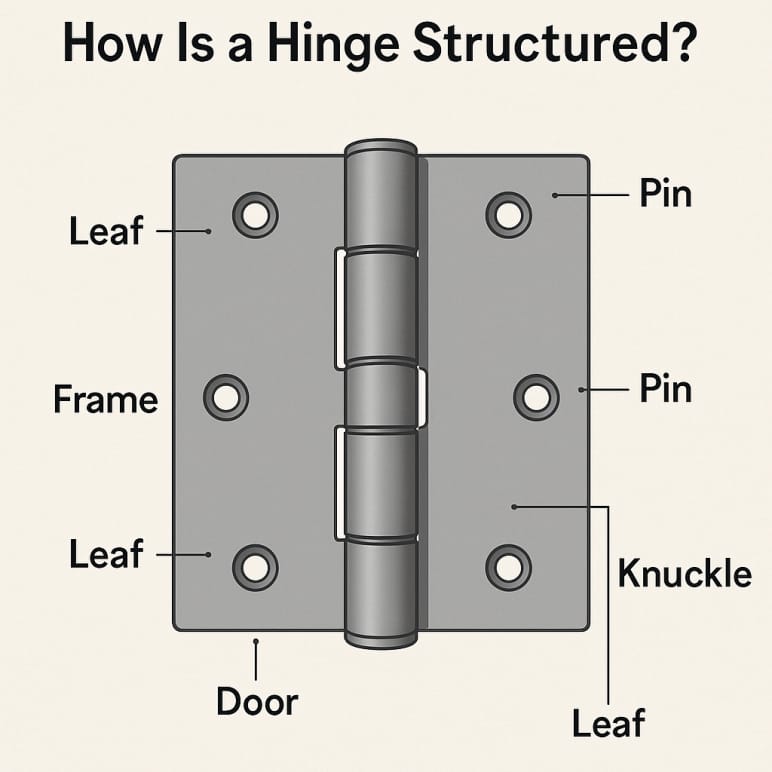

How Is a Hinge Structured?

A hinge is two plates joined by a pin. One plate goes on the frame, the other on the door or panel. The pin lets it open and close. That is the basic idea. From there, designs change: a long plate makes a piano hinge, a concealed version hides inside a cabinet or panel, and a spring lets the door close by itself. Materials also differ—zinc for light use, stainless steel for outdoor jobs, brass for a cleaner finish.

From there, designers tweak things: make the plates longer (piano hinge), conceal them inside industrial cabinets for a clean surface (concealed hinge), or add a spring so the door closes by itself. The material changes too—zinc for light jobs, brass for a nicer look, stainless steel if it needs to live outdoors.

How Did Hinges Develop?

Early doors used wooden pegs or stone sockets to pivot. Later, large iron strap hinges were common on gates and trunks—strong but heavy and easy to see. As machines improved, the butt hinge became standard for house doors. For cleaner looks, concealed hinges came in, followed later by soft-close designs. Industry then added stainless steel, sealed, and torque hinges for cabinets, equipment, and vehicles. The core idea stayed the same: two parts turning smoothly around a pin, adapted to each job.

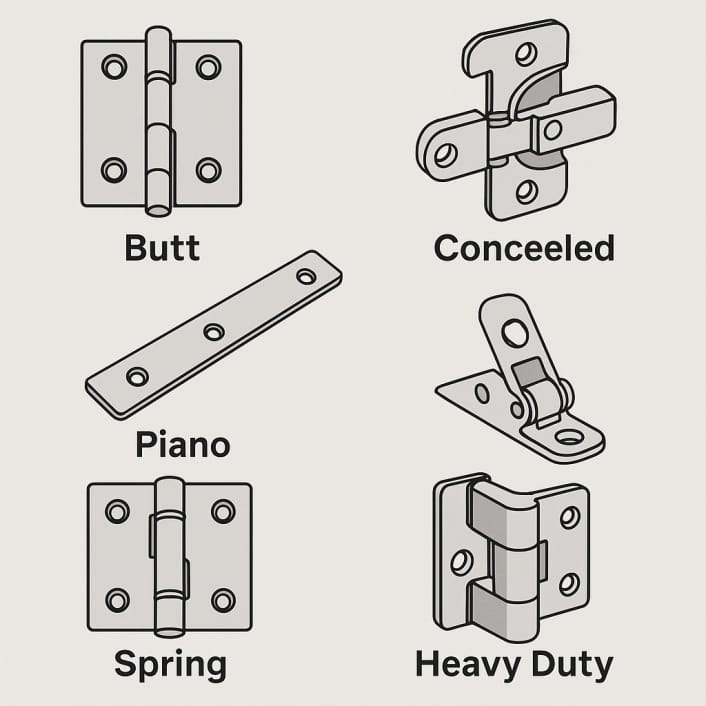

What Types of Hinges Are There?

Products don’t use the same hinge. Here are the main types:

Type | Best For | Pros | Cons |

Butt Hinge | Doors, gates | Strong, simple, easy to install | Visible, limited adjustment |

Concealed Hinge | Industrial cabinets, control panels | Hidden, adjustable, neat look | More complex install |

Piano Hinge | Long panels, lids | Even support along length | Not suited for heavy loads |

Spring Hinge | Self-closing doors, gates | Closes automatically | Tension may wear out |

Heavy Duty/Industrial | Vehicles, enclosures | Handles weight and vibration | Higher cost, larger size |

In Which Industries Are Hinges Essential?

Industrial Equipment

Electrical enclosures, HVAC units, and telecom cabinets open and close many times a day. Hinges here must resist dust, vibration, and weather. If they fail, downtime follows.

Automotive & Transport

Trucks, buses, and RVs rely on hinges in storage doors and compartments. These face constant shocks and harsh conditions. Weak hinges shorten the life of the door.

Marine & Outdoor

Salt water quickly damages poor hardware. Boat hatches and deck lids use stainless or coated hinges because failure at sea can be dangerous.

Appliances & Consumer Goods

Ovens, industrial washers, and instrument cases need hinges that work smoothly in daily use. Poor hinges squeak or loosen fast; good ones perform quietly for years.

What Makes Fornd Different As a Hinge Partner?

Certifications That Matter

Fornd operates an ISO 9001 / IATF 16949 certified plant. Every hinge is CE and RoHS compliant, ensuring smooth customs clearance worldwide.

Production Capacity at Scale

Fornd runs a 30,000 m² site with multiple lines for butt, concealed, piano, and heavy-duty hinges. This allows distributors to source everything in one place and scale orders without changing suppliers.

Fast Customization Options

Logo stamping, powder coating, or branded packaging can be done within a week. Small changes that make products stand out on the shelf.

Reliable Lead Times and MOQs

Orders start at 200 pieces with an average lead time of three weeks. The terms are clear from the beginning, so you always know what to expect.

Fornd Hinge Product Recommendations

Image | Product Code | Product Name / Type | Key Features | Link |

| Surface Fixed Hinge, 40×40 mm, Chrome Bright | Zinc alloy; surface mount; bright chrome plating; versatile indoor use | https://fornd.com/zh_CN/product/removable-lift-off-hinges-h1-2301-a1 | |

| Surface Fixed Hinge, 50×50 mm, Stainless Steel | Stainless steel; mirror polished; rust and corrosion resistant; better for humid or outdoor service | https://fornd.com/zh_CN/product/surface-mount-hinges-h1-2101-501-a1 | |

| Lift-Off Removable Hinge, Offset Knuckle, Polish | Allows door to be lifted off without tools; concealed mount style; zinc alloy / stainless variant available | https://fornd.com/product/constant-torque-hinges-h1-2423-400-30 | |

| H1-2423-601-40 | Constant Torque Hinge, 60×60 mm, Powder-Coated | Holds doors/panels at any angle; durable under frequent movement; suitable for industrial panels | https://fornd.com/zh_CN/product/constant-torque-hinges-h1-2423-500-40 |

| 135° Concealed Removable Hinge, Stainless Steel | Concealed when door closed; can be removed easily; polished finish; heavy-duty option | https://fornd.com/product/concealed-removable-hinges-h2-2352-a1a |

What Proof Backs Fornd’s Reliability?

Fornd isn’t just another factory with a shiny brochure. They’ve got 14 patents tied to hinges and latches, which shows they actually put work into improving designs instead of copying the same old parts. Their products pass CE and RoHS checks, plus extra ASTM and ANSI tests on the heavy-duty lines, so you can sell them worldwide without worrying about compliance. On the performance side, the hinges are tested for load, corrosion resistance, and cycle life—numbers that prove they’ll last in real use, not just on paper. Add to that 36 straight months of 100% on-time delivery (audited by SGS) and a client list that spans more than 70 countries, from global retailers to industrial buyers. That kind of consistency is rare in this space, and it’s why distributors stick with them.

FAQs

Are Hinges The Same As Latches?

No. Hinges let a door or panel move. Latches keep it closed. They do different jobs.

Can Hinges Be Used Outdoors?

Yes. Stainless steel and heavy-duty hinges are built for rain, dust, and vibration. With the right material, they last for years outside.

What MOQ And Lead Time Can I Expect?

Orders start at 200 pieces. Standard lead time is about three weeks. Custom finishes or branded packaging usually take one more week.

Can I Request A Custom Hinge?

Yes. Fornd can provide drawings, samples, and packaging options to match your project needs.

Becoming a Fornd hinge distributor. Email info@fornd.com, claim your 10% sample credit, and get your first container on the water in 25 days.