Ever had to chase three different factories just to fill one latch order—only to end up with late shipments, uneven quality, and a dozen emails lost in translation? It’s the kind of hassle that eats away at your profit margin and your patience.

That’s why more global distributors are turning to Fornd. With one ISO-certified plant, six dedicated latch production lines, and the ability to customize orders fast, Fornd takes the chaos out of sourcing and lets you scale without the headaches.

In this guide, we’ll walk through what latches are, the different types and where they’re used, the pros and cons you should know before committing, and how Fornd’s products and track record make them a partner you can actually rely on. By the end, you’ll know exactly why becoming a Fornd latch distributor could be the easiest way to grow your hardware business globally.

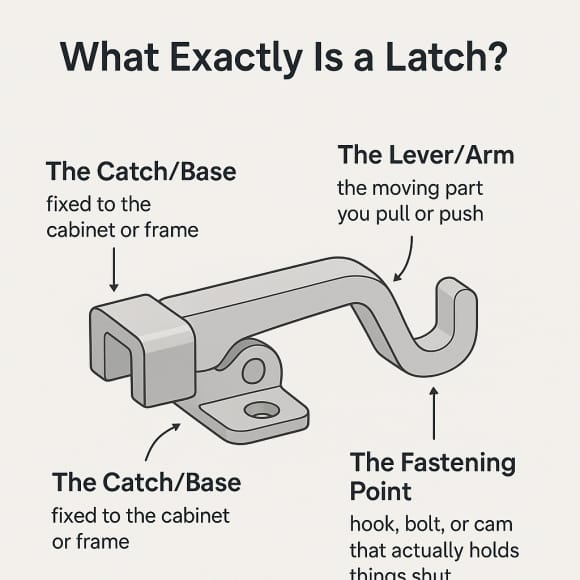

What Exactly Is A Latch?

A latch doesn’t always “lock.” Its main job is to hold things closed, reduce rattling, and give stability. Some latches also add sealing against dust or vibration.

Most combination latches are made up of three simple parts:

• The Catch/Base → fixed to the cabinet or frame.

• The Lever/Arm → the moving part you pull or push.

• The Fastening Point → hook, bolt, or cam that actually holds things shut.

Together, these pieces create the simple but effective mechanism we call a latch.

In Which Industries Are Latches Essential?

Latches can be seen in many industries.

Industry / Field | Common Scenarios | Why Latches Are Used |

Furniture | Desks, wardrobes, filing cabinets | Keep doors/drawers shut, reduce wear |

Industrial Equipment | Electrical enclosures, HVAC units, telecom boxes | Safety, sealing, vibration resistance |

Automotive & Transport | Truck compartments, buses, RV storage | Secure access, withstand vibration |

Marine & Outdoor | Boat deck lids, marine lockers, waterproof cases | Corrosion resistance, weather sealing |

Logistics & Packaging | Toolboxes, shipping containers, flight cases | Quick open/close, reliable closure |

Appliances & Consumer Goods | Ovens, washing machines, instrument cases | Everyday usability, safe operation |

Construction & Gates | Site gates, safety doors, machinery guards | Fast closure, worker safety |

What Types Of Latches Are There?

Think toolbox vs. telecom box—they don’t need the same kind of latch. Some are built for speed, some for sealing, and some for tough environments. Here’s a quick look at the main types and how they stack up:

Type | Best For | Pros | Cons |

Toggle Latch | Toolboxes, flight cases | Quick to open/close, cheap | Doesn’t provide security |

Draw Latch | HVAC, containers, cabinets | Creates a tight seal, vibration resistant | Needs clearance space to pull |

Spring Latch | Gates, doors, furniture | Auto-closing, easy to use | Limited holding power |

Compression Latch | Vehicles, telecom boxes, marine | Dust- and water-resistant, stable under vibration | Higher cost, more complex install |

Why Do Distributors Struggle With Latch Sourcing?

Still buying latches from three different factories? You know the pain:

Shipments Always Slip

When you’re working with a few different factories, deadlines are more like “suggestions.” One factory’s late, another blames logistics, and you’re the one stuck explaining delays to your customer.

Quality Is Hit Or Miss

One batch feels solid, the next batch rattles in your hand. Without one standard of QC, you never really know what’s going to show up in the container.

Endless Back-And-Forth

Every supplier has their own rules—different MOQs, different packaging styles, even different key-code systems. You end up spending hours just answering emails and chasing updates.

The result? Stress, extra costs, and orders that take way too much effort to land.

There’s a simpler way: stick with one factory that can actually handle it all.

What Makes Fornd Different As A Latch Partner?

At Fornd, sourcing latches doesn’t have to be complicated. Here’s why distributors stick with us:

Certifications That Matter

Every latch is built in an ISO 9001 / IATF 16949 certified plant. CE and RoHS compliance mean you can ship worldwide without customs drama. Safer for customers, smoother for you.

Production Capacity At Scale

A 30,000 m² site, six dedicated latch lines—toggle, draw, spring, compression—all in one place. That means fewer suppliers to chase, and capacity that grows with your orders.

Fast Customization Options

Need your logo stamped or packaging in your brand colors? Fornd can turn it around in just 7 days. Quick tweaks, big impact on how your product looks on the shelf.

Reliable Lead Times And MOQs

No vague promises here. MOQ starts at 200 pcs, standard lead time is 3 weeks. Simple numbers you can plan around.

Quick Snapshot

What You Care About | Why It Matters For You | How Fornd Makes It Easy |

Certifications | No drama at customs, safe to sell worldwide | ISO 9001 / IATF 16949, CE, RoHS |

Production Capacity | You don’t have to juggle five suppliers | 30,000 m² plant, 6 latch lines |

Customization | Products look like your brand, not generic | Logo stamping & packaging in 7 days |

Lead Time & MOQ | Easy to plan stock without nasty surprises | 3-week lead time, 200 pcs MOQ |

Which Fornd Latches Should You Know?

Here are some of Fornd’s latch products, designed for different industries and needs:

Image | Product Code | Product Name | Key Features | Link |

| F-1644-A1 | Over-Center Draw Latch (Self-Locking) | Stainless steel, self-locking over-center feel; clean finish (passivated); medium size for cases/panels | https://fornd.com/product/97-over-center-series-latches-f-1644-a1 |

| F-1645-57-10 | Under-Center Adjustable Draw Latch | Steel, adjustable grip, padlock-friendly; exposed mount; bright galvanized for durability | https://fornd.com/product/91-under-center-series-latches-f-1645-57-10 |

| F-1716-640 | Flexible Draw Latch | Glass-filled nylon (tough + light), concealed mount; good for coolers/cases; UL/REACH listed | |

| C8-1570-30 | Compression Latch (L-Handle) | 7 mm compression stroke; cuts rattle; anti-shock over-center; up to IP66 for dust/water | https://fornd.com/product/compression-locks-with-handles-c8-1570-30 |

| A-1446-100-30 | Sealed Lever/Thumb-Press Compression Latch | Streamlined look; pulls door tight to reduce wear; sealed design for exposed installs | |

| F-1901-412 | Push-to-Close Slide Latch (Snap-In) | Small, ABS, snaps into a single rectangular cutout; easy slide-to-open | |

| B-1519-20-40 | Paddle Latch (Flush-Mount Cup) | Lift the paddle to open; push-to-close; stainless + powder coat, large size

|

What Proof Backs Fornd’s Reliability?

Fornd doesn’t just talk about quality. They have numbers and records that back it up.

They own 14 patents. These cover latch designs and improvements. It shows they are building their own ideas, not just copying.

Their products pass CE and RoHS. Some models are also tested to ASTM and ANSI standards. That means they work in Europe, the US, and anywhere that asks for strict checks.

The lab results are solid. A sealed lever latch can handle 445 N of load. It can keep out dust and water up to IP66. That is the difference between a latch that rattles and one that survives outside for years.

Delivery is reliable. SGS audited them and confirmed 100% on-time shipments for three years straight.

And it is not only paperwork. Big clients already trust Fornd. Their Products are shipped to more than 70 countries.

FAQs

Are Latches The Same As Locks?

Nope. A latch’s job is just to keep something shut. A lock is what actually keeps people out. Think of a latch as “holding closed” and a lock as “blocking access.”

Can Latches Be Used Outdoors?

Yes. Go with stainless steel or compression latches if you’re dealing with rain, dust, or vibration. They’re built tougher and last longer outside.

What MOQ And Lead Time Can I Expect?

It’s pretty simple: MOQ is 200 pcs, and standard lead time is about 3 weeks. If you need your own logo or packaging, that can be sorted in just a week.

Can I Request A Custom Latch?

Of course. Fornd supports CAD drawings, prototyping, and custom packaging. That way you don’t have to settle for “generic”—you get exactly what fits your product.

Ready to move forward? Becoming a Fornd latch distributor is fast and straightforward. Just email info@fornd.com today, claim your 10% sample credit, and line up your first container shipment within 25 days.