Most people don’t think about latches—until the day a door won’t close, a box leaks in the rain, or an enclosure starts rattling from vibration. That’s when you realize this small piece of hardware decides whether the inside stays safe or exposed.

Fornd has built its reputation around making compression latches that solve exactly those problems. Designed for real-world use, they combine the strength of a cam latch with a built-in sealing action that keeps dust, water, and noise out. From electrical enclosures to telecom cabinets and industrial machines, Fornd’s compression latches are engineered to protect equipment and cut down on maintenance.

In this guide, we’ll break down what compression latches are, how they work, the benefits they bring, what to check before buying, and where Fornd’s own lineup fits in. By the end, you’ll know which latch makes sense for your next project—and how to get it.

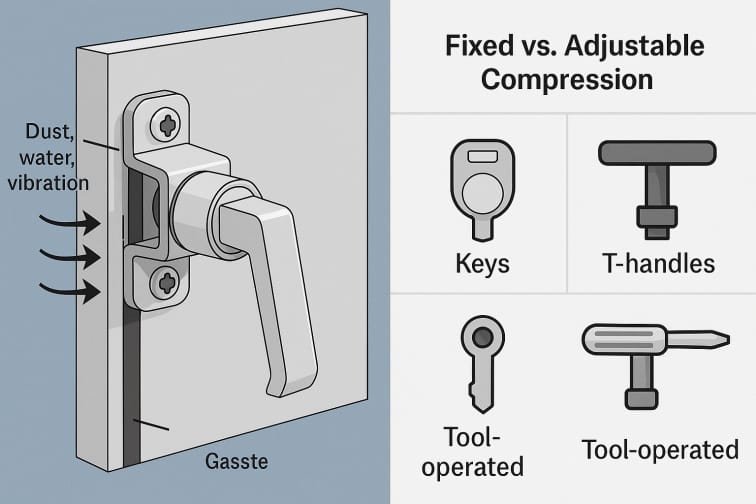

What Is a Compression Latch?

At first glance, a compression latch looks a lot like a regular cam latch—a base, a cam arm, and something you turn (a key, a handle, or a lever). But the real difference shows up when you close it. Instead of just catching behind a strike plate, the latch actually pulls the door in against a gasket. That squeeze is what creates the seal, keeping out dust, water, and even vibration. It’s why you’ll see compression latches on electrical boxes, telecom cabinets, HVAC units, and other gear that really can’t afford to get wet or shake loose.

Fixed vs. Adjustable Compression

• Fixed Compression – These are the “no-fuss” option. The depth and pressure are already set, so you just install them and they seal the same way every time. Great when all your panels are uniform and you don’t want to fiddle with adjustments.

• Adjustable Compression – More flexible. You can tweak the grip if the gasket wears down or if panels aren’t uniform. A lifesaver when tolerances aren’t perfect, since it saves you from constant rework.

How You Open Them

Compression latches come with different “handles,” depending on the job:

• Keys (tubular, flat, or hex) when you need security.

• T-handles or knobs for easy, frequent access.

• Tool-operated versions for restricted areas where only trained staff should get in.

Why Use Compression Latches Instead of Regular Cam Latches?

So here’s the big question: why not just stick with regular cam latches? They’re cheaper and everywhere, right? The answer is in the details.

Better Seal Against Dust and Moisture

A cam latch will keep the door shut, sure—but it doesn’t press the door tight against the gasket. A compression latch does. That squeeze makes all the difference: IP65+ level sealing that keeps out rain, dust, and anything else that tries to sneak in. Think telecom cabinets during a storm or outdoor electrical boxes—you’ll want that extra protection.

Quieter and Stronger Under Vibration

Machines, HVAC units, even generators—they all shake. A regular latch lets panels buzz and rattle, which gets annoying and wears things down. Compression latches push the gasket under pressure, so it absorbs vibration. That means less noise, less fatigue, and doors that don’t work themselves loose.

More Security Options

Need to keep hands out? Many compression latches come with built-in locks, padlock tabs, or tool-only access. That way, only the right people can get inside sensitive enclosures.

Still Easy to Install

Here’s the nice part: they don’t take a rocket scientist to fit. Most mount in the same way as cam latches—a cutout, some screws or rivets, and you’re done in 10–15 minutes. Adjustable models are even better for long-term use, since you can tighten them up when the gasket wears down instead of replacing the whole setup.

What To Consider Before Choosing One?

Before you pick a compression latch, it helps to think through where it will be used, how often it will be opened, and what kind of conditions it has to survive.

Application Requirements

Factor | Why It Matters | Real-World Pick |

Vibration Levels | If the box is sitting on a generator or gets jolted around in transport, a weak latch will rattle loose fast. | Go for a heavy-duty fixed or adjustable compression latch that holds tight. |

Panel Tolerances | Not every panel is perfectly even, and gaskets flatten with time. Without some wiggle room, the seal won’t last. | Adjustable compression latch with extra grip range keeps things sealed longer. |

Frequency of Access | A door you open every day needs to be easy on your hands. If it’s rarely touched, security can come first. | T-handle latch for daily use; keyed design if it’s mostly locked away. |

Panel Size & Weight | Big, heavy doors put real stress on hardware. A small latch alone won’t cut it. | Reinforced compression latch or even a multi-point setup for extra hold. |

Sealing Requirements | Sometimes it’s just dust; other times, it’s driving rain or washdowns. The latch makes a difference. | Stainless steel latch with a proven IP65+ rating. |

Safety / Security Level | If random people might try to get in, you need more than a twist-and-pull. | Keyed, padlock-ready, or tool-only compression latch to keep access controlled. |

Environment

The environment often makes or breaks a latch. Outdoor enclosures face rain, UV, and salt spray, which calls for stainless steel or powder-coated zinc alloy. In labs or factories with chemical exposure, chrome-plated or stainless designs resist corrosion better. For extreme hot–cold cycles, you’ll want robust finishes and durable gaskets so the latch won’t crack or loosen after just one season.

Installation Factors

Getting the cutout right is non-negotiable. Too large, and the latch won’t seat securely; too small, and you’ll struggle to mount it at all. Always double-check panel thickness against the spec sheet to avoid misfits. Accessories like dust caps, finger pulls, and spacers can also make the install cleaner and extend the latch’s lifespan.

Keys, Handles, and User Access

The way people open and close an enclosure shapes which latch works best. If you just need something simple, a flat key is the most familiar option. For extra security, tubular keys make it harder to tamper with. In restricted areas, tool-operated versions make sure only trained staff can get in. And if multiple people are using the same cabinet every day, adding a T-handle or even a padlock tab can make life easier without giving up safety.

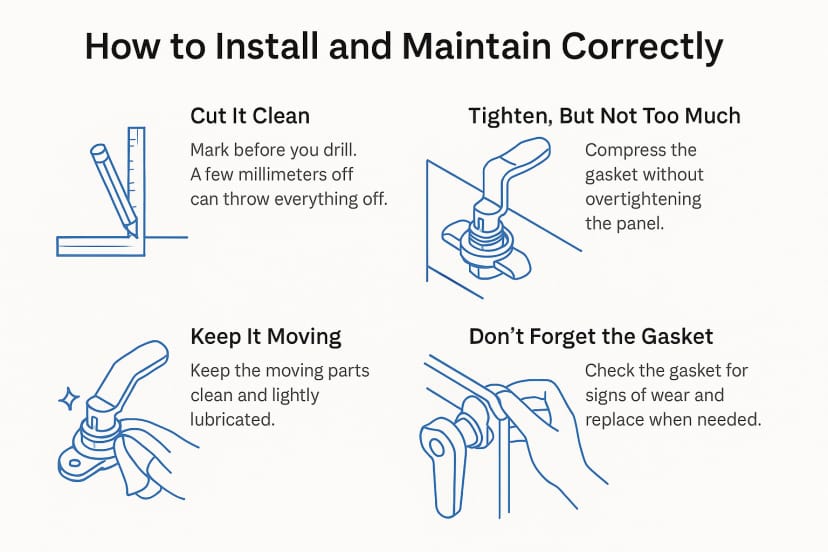

How To Install And Maintain Correctly

Step 1: Cut It Clean

Don’t just grab a drill and hope for the best. Take a pencil, mark it out, maybe even tape the spot first. A couple millimeters off and suddenly the latch doesn’t catch right. If there’s a template in the box—use it. Saves you from a lot of swearing later.

Step 2: Tighten, But Not Too Much

This is where most people mess up. You want the gasket snug, pressed just enough to seal. Too loose and water sneaks in; too tight and you crush the panel or kill the gasket before its time. Go for that “firm handshake” feel, not a death grip.

Step 3: Keep It Moving

Dust, salt, grease—hinges and latches pick it all up. Every once in a while, wipe it down and give it a tiny shot of lube. Takes a minute, and you’ll keep it turning smooth instead of grinding or squeaking.

Step 4: Don’t Forget the Gasket

Even tough gaskets get tired. They flatten out slowly, like an old pair of sneakers. Adjustable compression latches help you stretch their life, but don’t wait for leaks to show—check them now and then and swap them out when they look worn.

Fornd Product Spotlight

Fornd designs compression latches that balance durability, compliance, and ease of use. Here are a few real examples:

Product Image | Product Code | Name & Material | Key Features | Link |

| D3-1312-001 | Compression Cam Lock (Brass, Chrome-Plated) | 200 key variations, IP54, UL FTTA2/FTTA8 | |

| D3-1800-01 | Combination Compression Lock (Zinc Alloy/ABS) | 4-digit code + manager key, keyless access | https://fornd.com/product/combination-lock-d3-1800-01

|

| C8-1560-110-A1 | L-Handle Compression Latch (Stainless Steel) | Fixed spacing, K333 key, polished finish, outdoor-ready | https://fornd.com/product/compression-locks-with-handles-c8-1560-110-a1 |

| C1-1631-01-A1 | Compression Latch, Slotted Drive (Stainless Steel) | Adjustable pitch, compact footprint | |

| C8-1572-300-A1L | Heavy-Duty Lift & Turn Compression Latch (Stainless) | Large T-handle, adjustable, brushed finish | https://fornd.com/product/compression-locks-with-handles-c8-1572-300-a1l |

| C2-1403-147 | Railway-Standard Compression Lock (Stainless) | 7/8 mm square, fixed, passivated |

All Fornd compression latches undergo ISO 9001 quality checks, ASTM B117 salt spray testing, and CE/RoHS compliance audits—so they’re ready for export and installation worldwide.

FAQs

Does Panel Thickness Really Matter?

It does. If the panel is too thin or too thick for the latch’s spec, the gasket won’t seal right. Adjustable latches are handy here—they let you tweak the fit so everything stays tight.

Are Compression Latches Hard To Install?

Not at all. If you’ve got the right cutout and basic tools, they go in pretty quickly. Adjustable ones just add a small step to fine-tune the grip, but nothing complicated.

Can Compression Latches Be Used Outdoors?

Yes—just pick the right material. Stainless steel or powder-coated zinc alloy models are built to handle rain, humidity, and even sunlight without rusting out.

What’s The Difference Between Fixed And Adjustable Types?

Fixed latches give you a quick, consistent seal—great for simple jobs. Adjustable latches let you fine-tune the grip over time, which is perfect if gaskets wear down or panels aren’t all the same thickness.

Ready to upgrade your enclosures? Explore https://fornd.com/ to get compression latch collection and order today.