Fornd is a leading provider of high-quality industrial hinges, specializing in solutions that cater to the demanding needs of various industrial sectors. As essential mechanical elements, hinges provide pivotal motion control and adaptability across a wide range of applications, from heavy industrial equipment to commercial door systems. The structural and operational diversity of hinges is tailored to meet distinct load-bearing capacities, exposure to environmental stressors, and design preferences. The optimal selection of hinge configurations enhances operational reliability, prolongs service life, and ensures cohesive compatibility with a project's architectural and functional objectives.

Butt Hinges: The Industrial Workhorse

Butt Hinges: The Industrial Workhorse

Butt Hinges: The Industrial Workhorse

Butt hinges are what you refer to as versatile hardware that has two rectangular plates joined at the center by means of a pin. They are made of steel, brass, or stainless steel, and they are installed within mortises- the holes that are cut into the edge of the door and frame at industrial settings. Heavy-duty versions with ball-bearing action are preferable to highly trafficked entrances such as in a stockroom where there is much damage that can occur with the entrance mechanism. In such environments, stainless steel and galvanized versions offer excellent rust protection when placed in the exterior commercial facility.

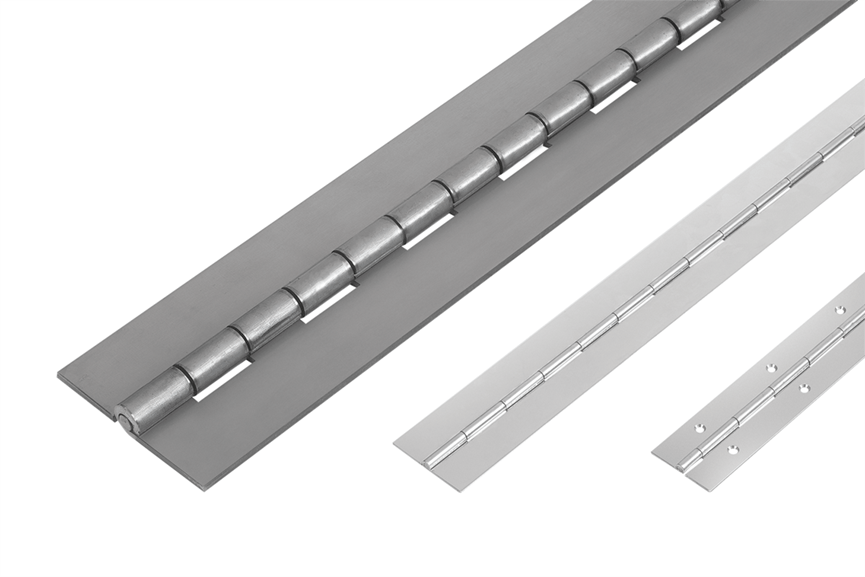

Piano Hinges: Long-Span Solutions

Piano Hinges: Long-Span Solutions

Piano Hinges: Long-Span Solutions

Continuous hinges, also known as piano hinges, span the full length of an interface to distribute mechanical loads uniformly. Constructed from materials like steel, aluminum, or brass, their monolithic construction delivers structural reinforcement for applications such as hinged lids on industrial machinery, collapsible work surfaces in assembly lines, and storage containers in warehouses. In aerospace engineering, these hinges anchor access panels on aircraft and fortify military-grade enclosures against rigorous use.

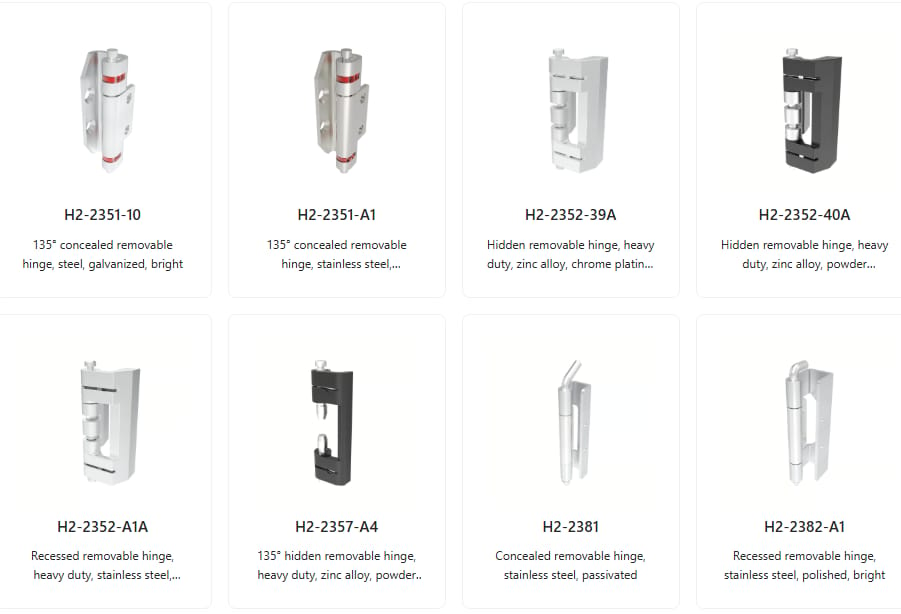

Concealed Hinges: Sleek and Functional for Industrial Design

Concealed Hinges: Sleek and Functional for Industrial Design

Concealed Hinges: Sleek and Functional for Industrial Design

Although more often than not associated with contemporary cabinetry design, concealed hinges can be adapted for use in industrial applications where a streamlined appearance is preferred. These hinges are fixed within the interior of the door and frame so that when the door is closed, they are visually imperceptible. Micro-adjustment screws present in these hinges allow for calibrations at a millimeter level, making it possible for the edges of doors to align perfectly with adjacent surfaces in sensitive industrial environments.

Fornd hinges are designed to make doors and panels functional but, more importantly, to give you a high-quality sensory and performance experience that will serve you throughout the life of your application, and beyond.

Pivot Hinges: Rotational Freedom for Large Assemblies

Pivot hinges allow the movement of doors by means of an axial mechanism maintained from top and bottom ends the most appropriate practical for large, very heavy door assemblies in conditions such as industrial. This includes monumental factory entrances, glass curtain walls for commercial offices, and even large access doors for equipment. This type of step away from using the central pivot pin can only lower the mechanical wear as well as tear, providing a relatively rugged option for places that would expose it to frequent operation.

Strap Hinges: Rustic Strength for Heavy Doors

Strap hinges have long, decorative leaves that extend beyond the pivot point and are typically further embellished with ornamentation. These were historically made from wrought iron, and are very much associated with barn doors, gates, or other heavy wooden structures often found within industrial landscapes. Their extended surface area helps to distribute weight more effectively, thus making them very suitable for heavy wooden doors or shutters in a warehouse or factory. The contemporary-type versions are of stainless steel or powder-coated and are meant for use in industrial installations that are beachfront; the two concepts, durability, and aesthetics, are combined.

Spring Hinges: Self-Closing Convenience for Safety

Spring hinges comprise hinges with a spring mechanism integrated in them, which automatically causes the door to close itself after being opened. They are essential in industrial environments where safety is paramount, such as fire doors or gates that require self-closing to comply with safety standards. Heavy-duty spring hinges are expected to be very reliable in these applications, with tension adjustments made to suit the weight of the door.

Flag Hinges: Versatile and Removable for Industrial Access

Flag hinges, also known as lift-off hinges, have a unique design concept with one leaf resembling a flag that permits quick lifting of the door off the pin. This is crucial for industrial use, such as having provisions for machine access panels or removable equipment covers. In industrial units, this applies to sliding barn doors or portable workbenches to offer quick disassembly. Stainless steel flag hinges also find wide application in marine industrial installations because of their resistance to corrosion due to saline water.

Overlay Hinges: Adjustable Fit for Industrial Cabinetry

Overlay hinges are meant for cabinetry where the doors overlay a part of the frame. They are commonly used in industrial kitchens, bathrooms, and storage units. Full, half, or inset overlay configurations cater to different door thicknesses and styles. Soft-close versions improve user experience, while heavy-duty models support larger pantry doors or entertainment units in industrial settings.

Case Hinges: Precision for Small Industrial Spaces

Case hinges are commonly applied to boxes, briefcases, or instrument cases in industrial environments. They are normally slim and precise in dimensions, making them ideal when there is a constraint to work with minimum space. In the case of luxury luggage or musical instrument cases used in the entertainment industry, they would normally have brass or nickel-plated finishes, which are extremely corrosion-resistant and attractive. They are also applied in the electronics industry to secure a laptop screen or any folding device stand in industrial workstations.

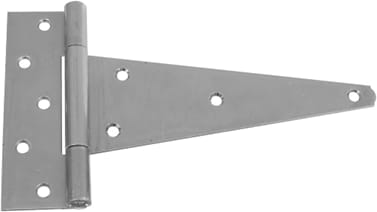

T-Hinges: Heavy-Duty Stability for Industrial Structures

T-hinges derive their name from their T-shaped design, with one long vertical leaf and a shorter horizontal leaf. They are a go-to for sheds, barn doors, and gates in industrial settings, where their robust construction handles heavy loads and harsh weather. Galvanized steel or powder-coated finishes prevent rust, ensuring longevity in outdoor industrial environments. Their simple installation and affordability make them a practical choice for agricultural or utility buildings.

Specialty Hinges: Niche Solutions for Unique Challenges

Specialty hinges address unique challenges in industrial applications. Hospital Hinges, for instance, are designed with a recessed profile to prevent snagging bedding or clothing, making them ideal for healthcare facilities. Butterfly Roof Hinges allow sections of roofs to open for ventilation in greenhouses or industrial buildings. Invisible Hinges for glass doors use adhesive or clamps, eliminating visible hardware for a floating aesthetic in modern industrial designs. Friction Hinges hold positions at any angle, perfect for laptop screens or adjustable monitor arms in industrial workstations.

Material Considerations for Industrial Hinges

The material choice significantly impacts how well a hinge will perform over time in industrial settings. Stainless steel does well in high humidity or high corrosion settings, such as marine industrial locations. Brass is cost-effective and still very resistant to corrosion, suitable for either interior industrial doors or furniture. Zinc alloys cover all indoor industrial uses and are quite inexpensive, while carbon steel is coated and more than capable of supporting industrial loads. Where temperatures are very high, high-temperature alloys prevent distortions in ovens, furnaces, and other industrial heat sources.

Installation and Maintenance Tips for Industrial Hinges

Proper installation ensures that hinges function optimally in industrial environments. Mortising hinges into wood prevents misalignment, while using pilot holes in metal avoids stripping screws. Lubricating pins with silicone spray reduces friction and squeaking. For outdoor industrial hinges, periodic cleaning and applying anti-corrosion coatings extend lifespan. Replacing worn hinges promptly prevents door sagging or structural stress, ensuring the smooth operation of industrial equipment and machinery.

Innovations in Hinge Design for Industrial Applications

Fornd stays at the forefront of hinge innovation, offering smart hinges with embedded sensors that monitor door position or usage patterns, integrating seamlessly with home and industrial automation systems. 3D-printed hinges enable custom geometries for prototyping or bespoke industrial furniture. Eco-friendly hinges made from recycled metals or biodegradable composites align with sustainable design trends in modern industrial settings.

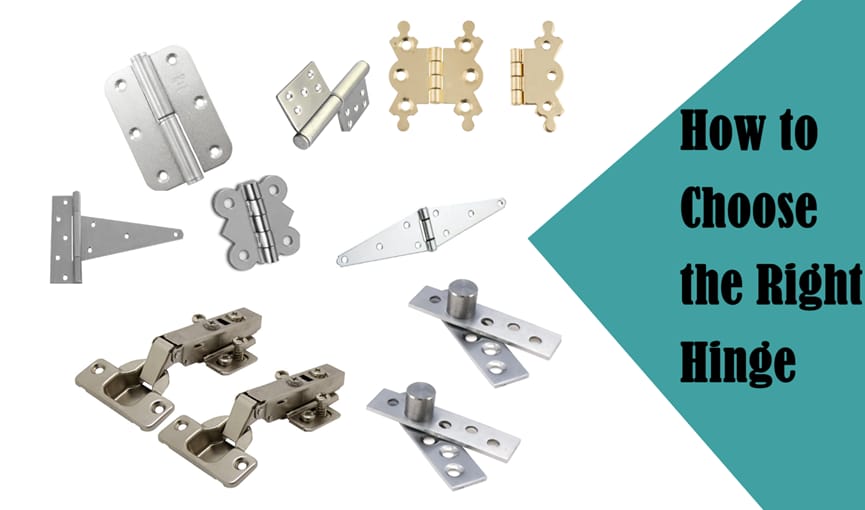

Choosing the Right Hinge for Your Applications

The selection of hinges for industrial applications is based on the load, environmental exposure, frequency of use, and aesthetic goals. Understanding the types of hinges and their advantages will ensure that users select solutions that are both functional and long-lasting, transforming static industrial objects into dynamic, user-friendly solutions. Hinges may be small, but their role in enabling movement and stability in industrial environments is monumental.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.