Hinge for Doors with Adjacent Cabinets 180° | External Hinges Review

Industrial doors are not glamorous, but when they jam, every technician notices. In machine enclosures and control cabinets, the humble hinge determines how smoothly maintenance happens—or how frustrating it becomes. A 180° external hinge might sound like a small detail, yet it’s what allows full access when two cabinet doors sit side by side.

Choosing the right hinge means balancing material strength, corrosion resistance, and installation ease. Stainless steel or die-cast alloys each perform differently under vibration, dust, or salt air. In this review, we’ll look at how 180° external hinges are built, what separates a reliable one from a weak link, and why they matter in industrial design.

Along the way, we’ll reference several current models, including Fornd’s stainless-steel EXH-180 series, to illustrate how modern engineering refines an old, mechanical idea.

What Is a 180° External Hinge and How Does It Work?

Basic Function

A 180° external hinge is designed to let enclosure doors open completely flat—flush with the cabinet wall—so technicians can access every component without obstruction.

Unlike internal hinges hidden inside the frame, external hinges mount on the outer surface of the enclosure, which provides a wider swing angle and easier door removal for adjacent-panel layouts.

How It Works?

In control panels or machine enclosures, doors often sit right next to each other. A 180° hinge lets one door open fully without hitting the next.

It uses a simple offset hinge line. The pin sits between two leaves with just enough spacing to clear the frame.

When the door turns, that gap lets it swing past the edge and rest flat. No scraping, no force—just a direct, mechanical movement built for everyday work.

What Materials Are Hinges Made of?

Body and Leaves

Most 180° hinges start with metal, but the type says a lot about where they’ll survive.

• Stainless steel (AISI 304 / 316) is a workhorse. It shrugs off rain, dust, and salt, which is why you see it on outdoor cabinets or along the coast.

• Zinc die-cast versions are cheaper and lighter. They’re fine for indoor panels, though they’ll age faster if the air is humid.

• Aluminum (6061-T6) sits somewhere in between—rigid, low-weight, easy to handle when a door needs to come off quickly.

Pin and Bushing System

That quiet, clean swing comes from the core mechanics.

• A hardened steel pin takes the weight and keeps the door aligned after thousands of opens.

• Around it, a PA6-GF30 bushing absorbs shock and cuts friction, so the movement feels solid instead of squeaky.

• Some higher-end models add a self-lubricating sleeve, which keeps everything smooth even if no one remembers to oil it.

Surface Finish and Coating

Finishing is where most cheap hinges fail first.

• Passivation or electropolish on stainless steel makes the surface denser and slows down corrosion.

• Powder-coated or chrome-plated zinc holds up better against grease and fingerprints.

• Anodized aluminum builds a hard skin that resists scratches.

Every good hinge should still pass the ISO 9227 salt-spray test—at least 48 to 72 hours without rust. If it doesn’t, it’s not built for real work. Fornd does well in this.

How Strong and Reliable Is It in Daily Operation?

Load Capacity and Fatigue

A standard 180° industrial hinge handles door weights of 15 – 25 kg per hinge, depending on the panel size.

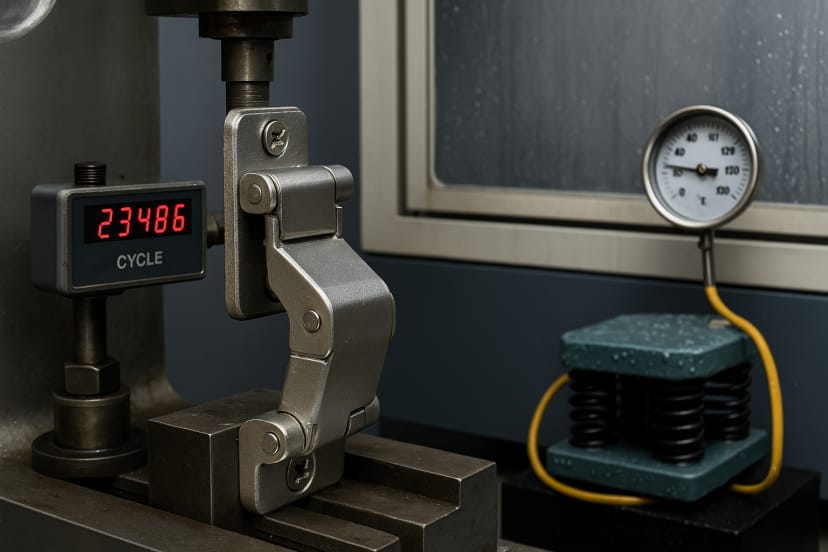

During mechanical endurance testing, most premium models exceed 20,000 open/close cycles without significant wear. The bearing design and pin hardness determine how long the hinge retains alignment.

Environmental Resistance

Industrial tests follow ASTM B117 for salt-spray exposure and DIN EN 60068-2-52 for vibration and humidity.

Under these conditions, a well-sealed hinge keeps its mechanical tolerance and corrosion resistance after prolonged exposure.

Temperature and Stability

Many stainless models withstand temperatures up to 150 °C, suitable for machinery enclosures with heat buildup.

For cold-storage or offshore applications, rubber gaskets or silicone washers are recommended to maintain seal pressure and reduce metal fatigue.

Where Can This Hinge Be Used in Industrial Settings?

Control and Electrical Cabinets

You’ll find these hinges first in control panels—places where doors often sit side by side.

Switchgear systems, automation racks, PLC enclosures… all need a door that opens fully so a technician can reach wiring and sensors without dismounting the panel.

A 180° hinge makes that simple; no scraping, no half-open frustration.

Machine Enclosures and Equipment Racks

On production floors, machines are packed close together. An external hinge lets a heavy steel door swing clear, giving mechanics room to check belts or replace filters without bumping the next unit.

The lift-off design also helps: one quick motion, the door’s off—perfect for servicing robotics cells or CNC housings.

Outdoor and Harsh Environments

Outside, the rules change. Cabinets on wind farms, solar inverter boxes, or roadside control stations face heat, dust, and salt.

That’s where stainless-steel 316 hinges earn their keep. They don’t seize up after a few storms.

You’ll see them on maritime power units, petrochemical site panels, and even public transport signal boxes, where corrosion kills cheap hardware fast.

Fornd’s version uses reinforced bushings to hold alignment even when humidity, vibration, and salt all hit at once.

Is It Easy to Install and Maintain?

Mounting and Alignment

Most 180° hinges use M5 or M6 screws and follow standard 25 mm or 40 mm center-to-center hole patterns, making them compatible with modular enclosure systems (like Rittal or Schneider).

Installation usually takes less than 10 minutes per hinge using basic hand tools.

Adjustability and Replacement

The lift-off function—where the door can be detached by removing lower screws—greatly simplifies service operations.

Technicians can replace hinges without dismantling the entire cabinet frame, saving downtime in field maintenance.

Maintenance Tips

Here are some useful maintenance tips for users.

Action | Key Point |

Lubricate every 6 months | A thin film of oil keeps the pin from biting or locking up, especially outdoors. |

Tighten screws once a year | Vibration loosens fasteners faster than you think. Tighten before the door sags. |

Wash with mild detergent | Wipe off salt and dust before they start pitting the metal. |

Treat small rust spots early | Don’t wait—clean, dry, and seal them. It stops corrosion from spreading. |

Check bushings for play | If the door starts to rattle, the nylon’s worn. Replace it before the hinge cuts into metal. |

Keep a spare set ready | Hinges fail in pairs. When one goes, the next one’s not far behind. |

How Does Fornd’s 180° External Hinge Perform

Image | Model | Materials | Key Features | Product Link |

| H2-2316-40 | Zinc Alloy, Powder Coated (Black) | Corner external hinge; compact; allows full 180° door rotation | |

| H2-2316-46 | Zinc Alloy, Powder Coated (Green) | Corner external hinge; quick install; 180° rotation | |

| H1-2231-40 | Zinc Alloy, Powder Coated (Black) | Corner external hinge; embedded-mount; 180° rotation | |

| H1-2230-40 | Zinc Alloy, Powder Coated (Black) | Corner external hinge; compact; 180° rotation |

If you operate in coastal, offshore, or chemical-plant environments, the EXH-180 Series offers a robust, maintenance-friendly alternative that aligns with IEC 60529 (IP protection) and RoHS compliance. Ready to compare specs? Browse Fornd’s hinges here: https://fornd.com/.

What Makes A 180° External Hinge Different?

It mounts outside the frame, clears adjacent doors, and lets the panel open flat for full access.

Can I Retrofit It On Existing Cabinets?

Usually yes—if your frame uses 25/40 mm hole patterns and there’s edge clearance for the leaf.

How Long Will It Last Outdoors?

Depends on material/finish. SS316 + proper coating resists salt and humidity far longer than zinc die-cast.

Do I Need Special Tools To Install One?

No. A drill, driver, and torque check are enough. Just match screw size and hole spacing before you buy.