This guide combines our hands-on industry experience with search intent insights, giving buyers practical direction and clarity.

What Are Industrial Fasteners and Why Are They So Critical?

Fasteners are the invisible backbone of modern engineering. From skyscrapers to smartphones, nearly everything we rely on is held together by some form of fastener.

In automotive manufacturing, they secure engines, chassis, and interiors.

In construction, structural bolts and anchors guarantee building integrity.

In aerospace, nickel-alloy fasteners withstand extreme stress and temperature.

In medical and defense, biocompatible and tamper-resistant designs protect lives.

We’ve seen firsthand how poor-quality fasteners can compromise entire systems. For instance, during one of our client audits, a batch of low-grade bolts failed under vibration within 48 hours — a costly mistake that could have been avoided by sourcing certified fasteners.

What Are the Main Types of Fasteners?

Industrial fasteners fall into two primary groups:

Threaded fasteners: bolts, screws, studs, and nuts. These allow secure, removable joints and are essential for applications requiring regular maintenance.

Non-threaded fasteners: rivets, pins, retaining rings. These provide permanent or semi-permanent connections in structural and high-vibration applications.

➡ Key difference: If you need flexibility and disassembly, choose threaded. If permanence and strength are priorities, go with non-threaded.

Which Materials Are Most Common in Fastener Manufacturing?

The choice of material determines strength, durability, and environmental resistance:

Steel: cost-effective, strong, widely used in construction and machinery.

Stainless Steel: high corrosion resistance, ideal for marine, food, and medical industries.

Brass & Bronze: durable, conductive, and decorative — common in plumbing and electrical applications.

Titanium: lightweight and ultra-strong, favored in aerospace and defense.

Plastics: non-conductive, corrosion-resistant, suitable for electronics and lightweight assemblies.

👉 Example: In our testing facility, stainless steel fasteners survived 500+ hours of salt spray exposure, while untreated steel began rusting within 24 hours.

How Do Manufacturers Ensure Quality and Standards?

Fasteners must meet strict certifications to be trusted in critical industries:

ISO 9001 — quality management

ASME/ASTM — material and performance standards

SAE Grades — mechanical properties for automotive fasteners

Mil-Spec — U.S. military requirements for defense-grade fasteners

We always recommend asking suppliers for material traceability reports and testing data. A reliable manufacturer won’t hesitate to provide these.

Who Are the Leading Fastener Manufacturers in China?

China has become a global hub for fastener production, supplying both standard and high-precision parts. Based on market reputation and client feedback, these are notable suppliers:

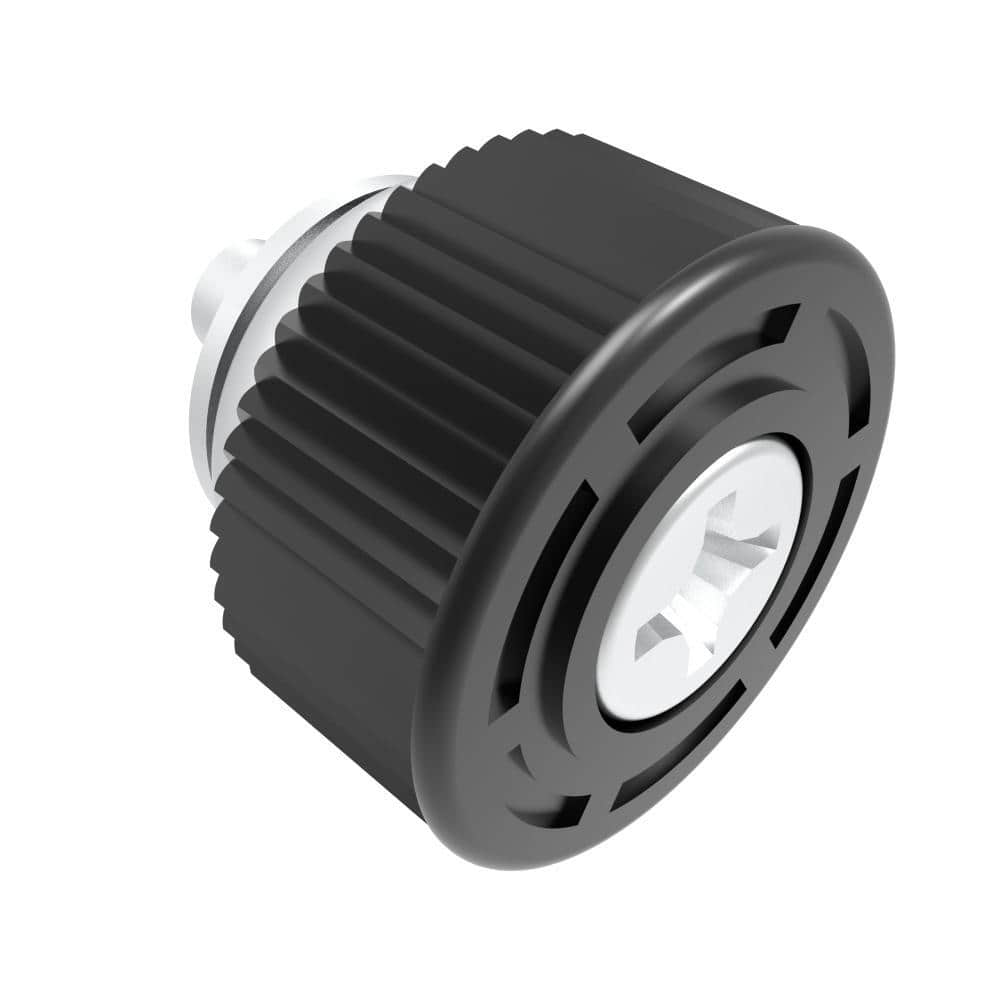

Fornd — Bolts, nuts, washers, screws, machining/stamping parts. Fornd is a fastener manufacturer, providing wholesale and customized fastener services.

We specialize in high-performance, durable locks with rapid production and delivery.

Our warehouse holds thousands of standard and custom locks in stock.

Jiaxing Qimu Trading Co., Ltd.

HISENER Industrial Co., Ltd.

Ningbo Fastenwell Metal Technology Co., Ltd.

Tong Ming Enterprise Co., Ltd.

Aozhan Industrial Co., Ltd.

Prince Fastener Manufacturing Co., Ltd.

When we benchmarked Chinese suppliers, we found lead time and QC processes vary greatly. Some deliver within 15–20 days, while others need 45+. Always confirm timelines upfront.

How Should You Choose the Right Fastener Supplier?

Before placing an order, ask suppliers:

Do they hold ISO/ASTM/SAE certifications?

Can they support custom design and provide engineering assistance?

What’s their production capacity and lead time?

Do they offer after-sales support and logistics solutions?

We recommend shortlisting 3–4 suppliers, requesting sample batches, and performing torque, corrosion, and fatigue tests before finalizing contracts.

What Are the Key Applications of Industrial Fasteners?

Fasteners play a pivotal role in:

Automotive: securing high-vibration components

Aerospace: lightweight alloys for flight safety

Construction: beams, panels, and heavy-load structures

Electronics: miniature screws for circuit boards

Medical devices: biocompatible and sterilizable components

Renewable energy: turbines, solar frames, hydro installations

Wherever strength and reliability matter, fasteners are the foundation.

Why Choosing the Right Fastener Supplier?

The OEM lock manufacturer or supplier you choose will affect how reliable, useful, and safe a product is, as well as how well it meets industry standards. The right business partner can make locks that can handle vibration during heavy shipping, suggest materials that won't rust in marine environments, and make sure that big manufacturing runs always have enough of them.

About Fornd

Fornd is a leading lock manufacturer and supplier in China. We specialize in high-performance, durable locks with rapid production and delivery. Our warehouse holds thousands of standard and custom locks in stock. If you can’t locate what you need, please contact our sales team—we’ll promptly source the right product for your application. Welcome to place your order!