Most of us never think twice about cabinet latches—until one stops working. That little “click” when a door shuts is easy to ignore, but it’s what keeps equipment safe, doors aligned, and daily routines moving without a hitch.

At Fornd, we’ve spent years fine-tuning that click. Our latches aren’t just pieces of hardware; they’re tested against real-world standards like IP65 and NEMA 4/4X, built from stainless steel, zinc alloys, and reinforced plastics to survive vibration, moisture, and even salt air.

In this article, we’ll walk through what a quarter-turn latch really is and how it works, highlight the differences between cam lock door latches and quarter-turn designs. We’ll also touch on what variations suppliers offer—materials, grip ranges, and security levels—and why bulk buyers often turn to Fornd for latches.

What Is a Cabinet Latch?

A latch is the part of a cabinet that keeps the door shut until you decide to open it. Unlike hinges, which provide motion, latches provide security and stability. In industrial settings, this becomes critical: a latch is what prevents a heavy machine door from popping open under vibration, or a server rack from shifting when someone leans against it. A good latch feels effortless to operate but strong enough to inspire confidence.

What Types of Latches Does Fornd Offer?

Fornd has spent years developing latches designed specifically for industrial cabinets, server racks, and enclosures. Below are four representative products from our catalog. Each one is engineered with durability, safety, and usability in mind.

Product | Type | Image | Description | Link |

Push-to-Close Latch B-1701-10-2P | Push Button |

| Snap-close latch with optional key lock. Made from PA66+30%GF plastic, tested to UL94-HB for flame resistance. Reliable for tool cabinets and electrical panels. | |

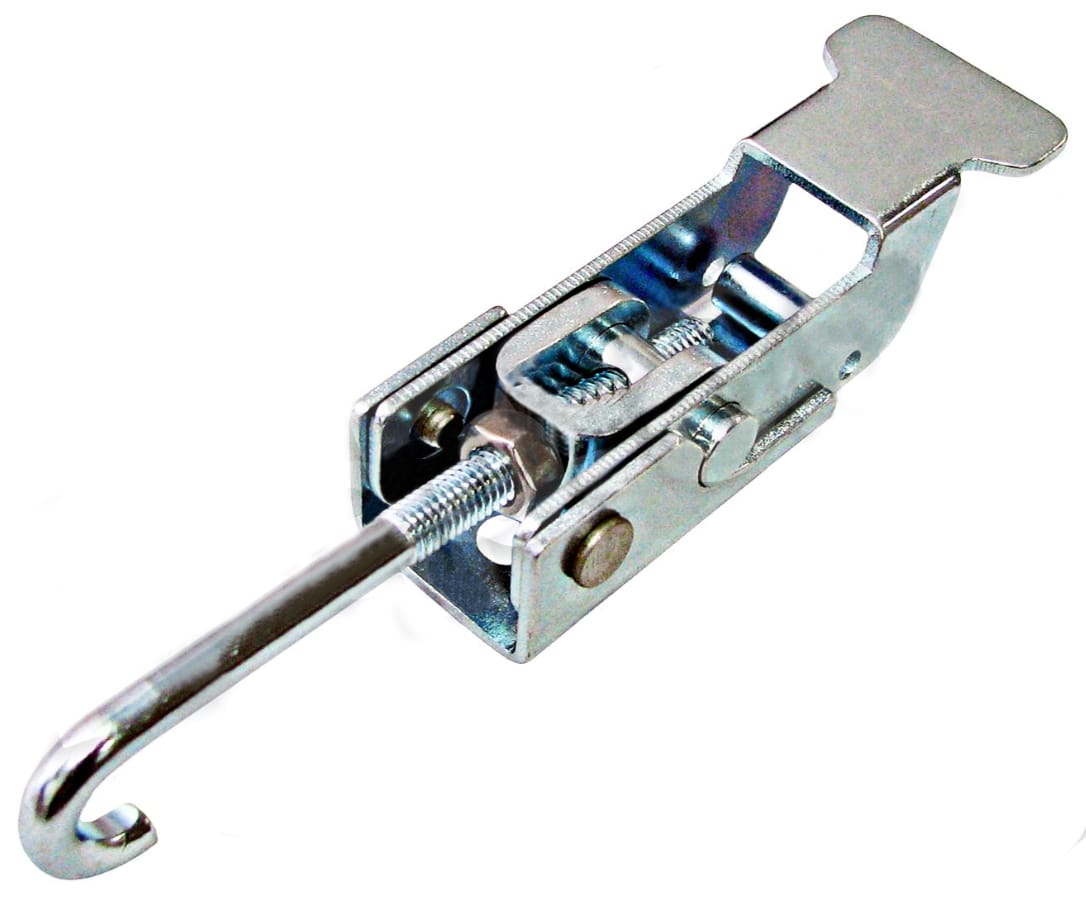

D1-1441-120-A1 | Cam Latch |

| A simple quarter-turn latch that you twist to lock or unlock. Made in stainless steel or zinc alloy, it’s sealed tight against dust and rain (IP65), which is why you see it so often on telecom enclosures. | |

Snap-Fit |

| Lightweight plastic latch that presses into place. Corrosion-resistant and cycle-tested for repeated use, max load 90 N. | ||

| Recessed Handle |

| Latch with integrated pull handle that sits flush with the panel. Made from stainless or polycarbonate. Compact and discreet. |

Where Are High-Quality Latches Essential?

Industrial latches show up in more everyday places than most people realize. Whenever a door or panel has to stay shut until you choose to open it, the latch is doing quiet but important work. Here are a few key spots:

Server Racks and Data Centers

Network gear can’t afford surprises. A quarter-turn cam latch with IP65 sealing keeps racks closed tight, so dust and vibration don’t mess with uptime.

Heavy Machinery Panels

Machine doors need to stay locked while equipment is running. Fornd’s compression and push-button latches make sure panels stay put and workers stay safe.

Construction Site Cabinets

Job site storage takes a beating—dust, bumps, and rough handling every day. Powder-coated zinc-alloy latches hold up to that abuse without constant replacements.

Outdoor Telecom Boxes

Rain, dust, and even tampering are daily risks for outdoor enclosures. Stainless steel and coated latches tested to NEMA 4/4X standards keep those boxes sealed and secure.

What Features Define a Reliable Industrial Latch?

Not all latches are built the same. What sets an industrial-grade latch apart are the choices in material, finish, and how it’s tested for the real world.

Material Strength

We use stainless steel, zinc alloy, and reinforced plastics like PA66+30%GF. These stand up to rust and impact far better than cheap stamped steel.

Material | Why It Matters |

Stainless Steel (304 / 316) | Stays strong even in rain or salty air. 316 is the heavy-duty pick for marine use. |

Zinc Alloy (Zamak 3 / 5) | Tough and versatile. With coating, it resists wear and still looks polished. |

Aluminum Alloy | Light but sturdy. Good for cabinets where weight matters. |

PA66 + 30% GF (Reinforced Nylon) | Plastic boosted with glass fiber—lightweight, stiff, and impact-resistant. |

Polycarbonate (PC) | A tough plastic that holds up to knocks and drops. Often used in flush-pull or snap-in latches where you need strength without adding weight. |

Surface Treatment

Powder coating, anodizing, and polishing aren’t just for looks—they keep the latch from wearing out too soon. In salt-spray tests, Fornd latches last over 500 hours, showing they can handle rough, corrosive environments.

Sealing and Vibration Resistance

Our cam and compression latches are tested to NEMA 4/4X, which means they keep out dust and water and don’t loosen even when the whole cabinet shakes.

Endurance Testing

Push-to-close and quarter-turn latches are run through more than 50,000 open/close cycles, meeting the durability marks you’d expect from UL-tested hardware.

These aren’t just lab stats—they’re the reason a Fornd latch won’t quit on you the day you need it most.

Why Choose Fornd for High-Quality Latches?

Picking latches might feel like a small decision, but if they fail, you’ll notice right away. That’s why a lot of teams stick with Fornd—we’ve built our reputation on making sure the little things don’t let the big things down.

Built to Global Standards

Every latch gets pushed through UL and NEMA testing. In plain terms, that means it won’t rust out in the rain, rattle loose when machines shake, or give up after a few years outdoors.

Easy to Customize

Not every project fits an off-the-shelf part. Need a latch in stainless steel instead of zinc? Or a different finish so it matches your enclosures? We’ll tweak the details so it actually works for your setup.

Engineering Support That Saves Time

Instead of shipping a mystery box, we share CAD files and samples upfront. That way your team can test the feel, the fit, and make changes before the order goes big.

Delivery Without Headaches

We’ve got global shipping sorted, so you don’t have to sit around wondering if your order is stuck halfway across the world. Lead times are shorter, and boxes show up when you need them.

Already Trusted in the Field

Fornd latches are out there right now—on telecom racks, heavy machinery, and construction gear. They’re the kind of parts people forget about because they just keep working, cycle after cycle.

Your cabinets deserve hardware that works the first time, and the thousandth time. With Fornd, that’s exactly what you get.

FAQs

What Are the Main Types of Latches?

The big three are quarter-turn, compression, and push-to-close. Quarter-turns are the everyday cabinet choice, compression latches seal tighter, and push-to-close ones are for quick access.

How Do Norfolk and Suffolk Latches Differ?

They’re old-style door latches: Norfolk has a thumb lever and backplate, while Suffolk is a simpler one-piece. Fornd focuses more on industrial latches than these traditional types.

What Is a Plastic Latch?

Basically, it’s a latch made from strong plastic instead of metal. They don’t rust, they’re light, and they’re handy for indoor cabinets or places where weight matters.

Should I Get a 3-Inch or 4-Inch Latch?

Think simple: thinner, lighter doors usually do fine with 3-inch. If the door is heavier or thicker, go with 4-inch so it feels solid and doesn’t wiggle.