Most of us don’t think much about the small locks we use every day. The one on the mailbox, the cabinet in the office, the meter box on the side of the building—they all use the same quiet piece of hardware: a barrel lock. It’s not flashy, but it does the simple job of keeping things shut and safe.

Fornd makes these locks for real-world use. Their barrel locks come in different sizes and finishes, built to handle everything from indoor furniture to outdoor utility boxes. The idea is straightforward: make a lock that lasts, whether it faces daily handling or harsh weather.

In this guide, we’ll walk through what a barrel lock is, the main types you’ll come across, and the places they’re most often used. We’ll also look at the key points to consider before buying, and where Fornd’s products fit into the bigger picture.

What Exactly Is a Barrel Lock?

A barrel lock, or lock cylinder, is the small piece in a lock that actually decides whether your key works. You put the key in, turn it, and if everything matches, the lock gives way.

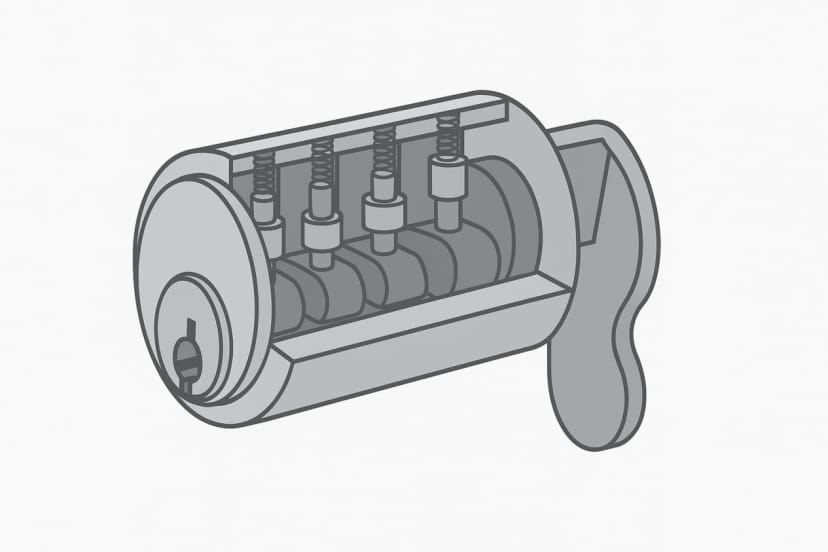

Inside, the setup is not complicated, but it’s precise.

The round body is the shell, holding the mechanism together.

The keyway is the slot—its shape alone decides what kind of key can even go in.

The plug sits inside, ready to rotate, but only when the small pins or discs line up with the cuts on your key.

Tiny springs keep those pins pushed down until the right key lifts them into place.

It’s a simple chain of actions: wrong key, nothing moves; right key, the pieces line up and the plug turns. That’s all it takes to keep a cabinet closed, or a meter box sealed day after day.

What Types of Barrel Locks Are There?

Here are common kinds you’ll find, and where they tend to shine:

Type | How it Works | Common Use |

Pin-Tumbler | The “normal” kind most people know. The key lifts pins to the right spots, then it turns. | Everyday doors |

Disc Detainer | Works with rotating discs instead of pins. Much harder to pick. | Utility boxes, higher-security cabinets |

Wafer Cylinder | Uses thin wafers. Cheap to make and easy to use, but not very strong. | Mailboxes |

Tubular / Radial | Needs a round key with notches around it. Small and neat. | Vending machines, bikes, tool locks |

High-Security / Restricted | Has extras like anti-drill parts or special keyways. Hard to copy keys. | Places where security and key control matter |

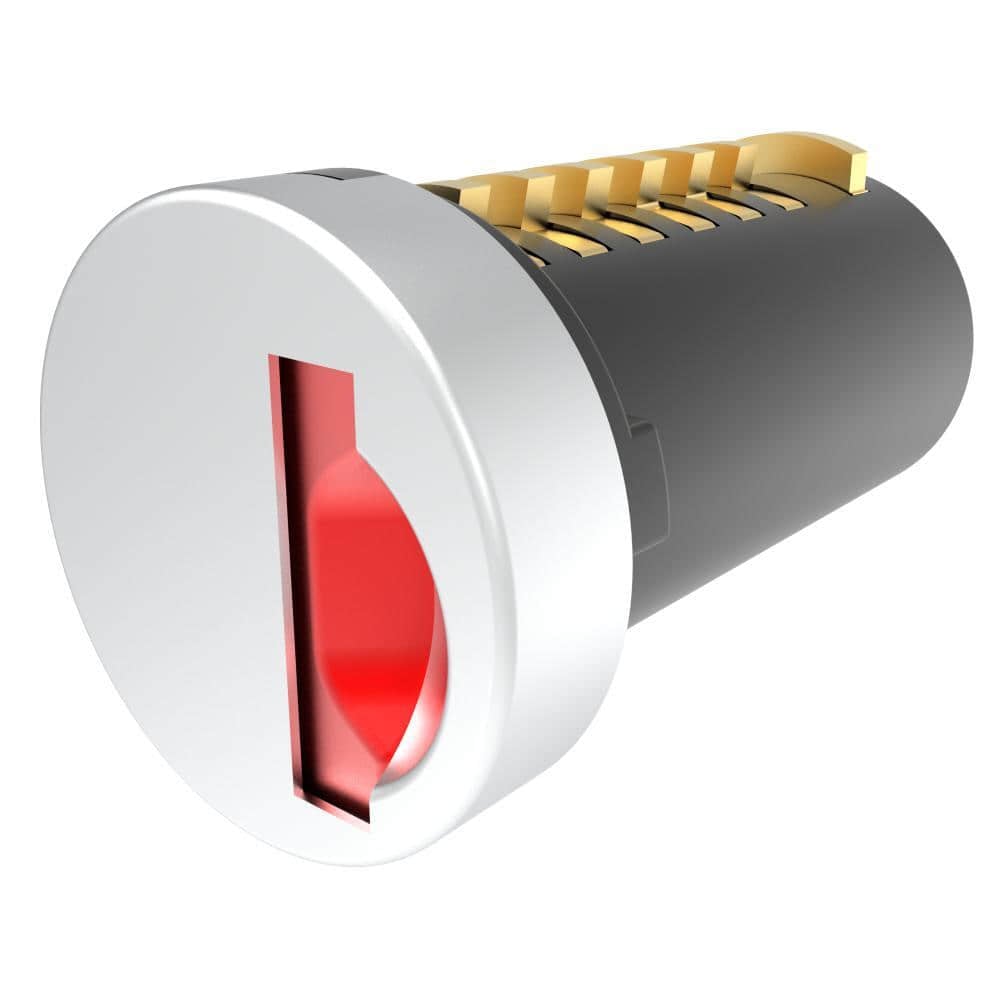

Fornd’s Barrel Lock Examples

Here are some Fornd lock cylinders that show how they cover types in real life. Helps you see features up close.

Image | Code | Material / Finish | Key / Core Style | Quick Notes | Link |

| 9302 | Stainless steel, passivation | Crescent-style core (“5 marbles”) | Stainless build for harsher environments; customizable key combinations. | |

| 9346 | Zinc-alloy body; electro-zinc-nickel; stainless cover; brass blade | Keyed core | Balanced cost vs. corrosion resistance; common cabinet core. | |

| 9347 | Zinc-alloy body; electro-zinc-nickel; stainless cover; brass blade | CH751 key locking | CH751 ecosystem; easy service in fleets/facilities. | |

| 9345 | Zinc-alloy body; electric galvanizing; stainless cover; brass blade | Keyed core | Budget-friendly indoor choice; multiple key combos supported. |

Where Are Barrel Locks Used?

People use barrel locks in lots of everyday and heavy duty places:

Utility and Meter Boxes

Barrel locks are always used on power, gas, and some water meter boxes. They don’t need to look fancy—what matters is that they stay tough and only let the right people open the panel when service is needed.

Vehicles and Transport Units

Trucks, trailers, and RV storage doors rely on barrel locks too. Roads shake, vehicles rattle, but these locks hold firm. Close them once and they stay put, even on long trips.

Vending and Service Machines

From vending machines to ticket kiosks, these units are out in public all day. A barrel lock acts as the first line of defense, keeping cash, stock, or parts safe from tampering.

Lockers and Mail Systems

Mailboxes and public lockers often use barrel locks because they can handle constant daily use. They open quickly when needed, yet still give people confidence that their things are secure.

What Factors Influence Choice and Performance?

Material and Corrosion Resistance

• Brass — Feels steady in the hand and usually works smoothly with keys. It can start to look dull or spotty if the air is damp for too long.

• Stainless Steel — This one just shrugs off rain and even sea air. It does the job outside without fuss. The only catch is it’s heavier and costs more.

• Zinc Alloy — People go for it because it’s cheap and easy to shape. The downside is, once the shiny plating gets scratched, it can wear down fast.

• Aluminum — Super light, quick to install, no rust problems. But it dents or bends if you try it on a heavy panel.

• Steel with coating — strong and feels tough. Still, once the coating chips, rust shows up quicker than you’d like.

Size, Barrel Length, and Keyway Fit

The barrel has to match the panel thickness, and the keyway must work with your key set. A mismatch means the lock won’t sit right or the key won’t turn smoothly.

Resistance to Picking, Drilling, and Tampering

High-security barrel locks add small tricks that slow people down. It can be extra pins that block simple picks, hardened parts that make drilling harder, or a keyway shape that only fits the right blank. These won’t make a lock unbreakable, but they turn a quick job into a tough one.

Environmental Resilience

Locks often face dust, moisture, and big swings in temperature. If a lock jams or rusts, security doesn’t matter. Picking the right finish or gasket can make the difference.

Key Control and Replacement Cost

Restricted keyways and master systems give better control but cost more. Losing a restricted key means paying extra and waiting longer for a replacement.

How Do Barrel Locks Compare to Alternatives?

Barrel locks are compact, relatively secure, and replaceable without changing the whole lock body. But other types like cam locks, mortise locks, or electronic cylinders may offer:

Lock Type | Why People Use It | Where It Works Best | What to Keep in Mind |

Barrel Lock | Small, neat, and easy to swap without touching the whole lock. Gives decent security in a compact form. | Utility boxes, vending machines, lockers, meter panels. | Not as strong as mortise, not as “smart” as electronic. |

Cam Lock | Simple and cheap. Just turn the cam arm to keep the door shut. | Display cases, cabinets, other light-duty spots. | Very low on security. Easy to bypass if someone tries. |

Mortise Lock | Bigger build, thicker bolt, and strong leverage. | Building doors, gates, heavy-duty enclosures. | Needs more space, harder to install, not a quick swap. |

Electronic Cylinder | Can unlock with a fob, keypad, or even a full system. Can track who opened it. | Smart lockers, high-end access control, secure enclosures. | Needs power and wiring, more expensive, can be tricky outdoors. |

FAQs

What’s the Difference Between a Barrel Lock and Cam Lock?

A barrel lock is just the cylinder where your key turns. A cam lock is the part that actually turns the cam (the back bit) after the key. Barrel is about key/lock internals; cam is about what moves after.

Can Barrel Locks Be Shared Among Many Doors?

Yes—if they’re master-keyed or keyed alike. But you usually lose some security or increase cost. If you share keys, pick restricted keyways.

Do I Need Special Tools to Measure Barrel Length / Keyway?

Not much. Measure panel thickness and make sure the barrel isn’t too long or protruding. Compare keyway types. If in doubt, send a photo to the supplier or use a template.

How Long Do Barrel Locks Usually Last Outdoors?

It depends hugely on material and finish. A stainless or well-plated lock can go years. Cheap zinc or unprotected alloy will degrade fast, especially in rain or salty air.

It's time to go to Fornd’s Cabinet Lock Cylinder or Stainless-Steel Industrial Locks pages. Visit https://fornd.com/product now and order what you want.