Many different industrial environments feature mechanical devices known as cabinet latches holding panels, enclosures, and access points. Choosing the right latch ensures good closing, vibration resistance, and effective access from telecom boxes and electrical cabinets to heavy equipment doors. Especially for the industries of machinery, transportation, communications, and energy, Fornd provides a large selection of cabinet latches. This book looks at most common trends, performance issues, and choosing strategies to guide your decisions.

Common Types of Cabinet Latches

• Cam Latches

Cam latches engage behind the panel frame using a rotating arm, quarter-turn motion securing access. Made from zinc or stainless steel, Fornd offers basic, tool, or knob-actuated styles. They find application in HVAC cabinets, electrical enclosures, and simple machinery access doors.

• Compression Latches

Compression latches mix mechanical closure with gasket compression, good for dust and water sealing. Fornd's models abound in adjustable grip ranges and vibration resistance. Often seen in outdoor telecom cabinets, transport boxes, and climate-exposed equipment enclosures.

• Push-to-Close Latches

Push-to-close latches snap shut with light pressure; they do not call for rotation. Available in corrosion-resistant materials, Fornd's models use either magnetic retention or spring-loaded action. These latches fit indoor panels, toolboxes, and lightweight sections needing quick, one-handed closure with minimum effort.

• Draw Latches

Draw latches tightly together under tension by means of a lever and loop mechanism. Strong closure is maintained by Fornd's adjustable models even in cases of panel flex or shift. Battery housings, mobile gear enclosures, and industrial containers all feature them often.

• Quarter-Turn Latches

Quarter-turn latches locking with a 90-degree turn provide fast access and consistent closure. Fornd several sized sloped, hex, or triangle-head designs. These fit utility cabinets, server racks, and any space with limited clearance and frequent access.

• T-Handle Latches

T-handle latches with their great torque and leverage fit heavy doors and rough access points. Fornd offers solid metal shaft models both locked and non-locked. Industrial machine covers, transport lockers, and generator enclosures all find use for them.

• L-Handle Latches

With a more compact grip than T-handles, L-handles provide revolving action. Among Fornd's models are internal and external mounting choices, some with cam or rod integration. In mechanical service compartments, mid-sized panels, and modular switchgear they are rather popular.

• Magnetic Latches

For closure without mechanical contact, magnetic latches depend on embedded magnets. Indoor uses like test stations, light equipment covers, or cabinet doors where soft closure and simplicity of use are critical findnd's polymer versions are perfect.

• Slam Latches

Perfect for quick, tool-free access, slam latches automatically when a door closes. Fornd's slam latches provide dependable locking for mobile equipment doors, storage bins, and vehicle panels as well as withstand repeated impact.

• Paddle Latches

Paddle latches use a wide, flat lever that’s easy to grip, even with gloves. Fornd’s models include flush-mount types with optional key locks. Commonly seen on tool compartments, vehicle storage, and agricultural machinery doors where access speed matters.

• Multi-Point Latches

Multi-point latches provide even pressure along tall or wide doors through rod-actuated systems. Fornd designs these for use with T- or L-handles in large cabinets, telecom shelters, and generator housings. They’re essential when a single latch won't hold the door evenly.

• Tool-Operated Latches

These latches open only with specialized tools—such as triangle keys or Allen wrenches—offering basic security without keyed systems. Fornd’s tool-operated models are used in test equipment, utility boxes, and restricted enclosures where unauthorized access must be discouraged.

Key Performance Considerations

Built to remain secure under movement, fornd latches use spring-loaded cams and anti-rattle elements for vibration resistance. In demanding environments, gasket supported compression designs guarantee sealing against dust and moisture. Strength and durability are added by materials including reinforced polymers, zinc alloy, and stainless steel with either chrome or powder coatings. Fornd provides flush and surface-mounted models to fit different space needs.

How to Choose the Right Latch

Step 1: Identify Door Requirements

Review panel weight, size, and anticipated access frequency. Lightweight panels may use magnetic forms; heavy doors need compression or paddle latches.

Step 2: Assess Security Needs

Select tool- or key-operated latches for limited access. Go with slam or push-to-close techniques if quick access is crucial.

Step 3: Match Environmental Exposure

Outside use calls for corrosion resistance. Fornd advises in marine or dusty zones stainless or treated zinc latches.

Step 4: Confirm Mounting Constraints

Find whether specific designs are limited by surface space or door thickness. Where little projection is required, use flush-mount.

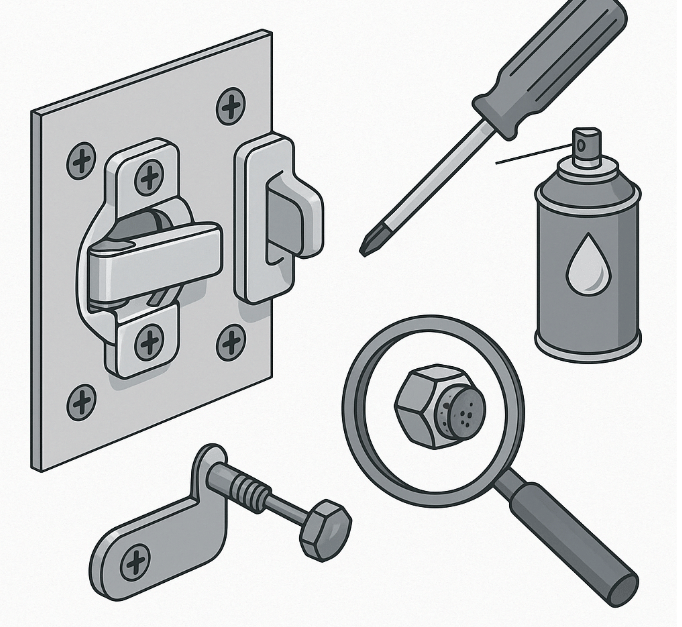

Installation & Maintenance Tips

Exactly line the keeper and latch. Choose fasteners suitable for the panel material and latch. Spray silicone grease on moving parts to help them last. Occasional check for loosened or corroding fittings Early replacement of old units helps to avoid access issues.

About Fornd

Designs and manufacturers industrial-grade cabinet latches, handles, hinges, and locking systems for demanding environments. Worldwide manufacturing equipment, power control boxes, transit systems, and telecom shelters rely on our products. With a wide range of products, sample support, and engineering customizing, Fornd helps customers guarantee consistent enclosure access in all sectors. Invest more at fornd.com.