This article is created by Fornd, drawing on our years of experience in industrial lock design and engineering.

What defines a heavy duty door hinge manufacturer in today’s market?

A heavy duty door hinge manufacturer is a producer capable of designing, machining, finishing, and verifying hinges that reliably carry high static and dynamic loads in industrial environments. In practice, that means: (1) documented load rating (per hinge and per door leaf), (2) cycle life validation at rated torque, (3) corrosion resistance (salt-spray hours), (4) environmental sealing where applicable (e.g., IP for integrated components), and (5) consistent dimensional tolerances for repeatable fit.

At Fornd, we classify “heavy duty” as hinges supporting doors or panels ≥ 50 kg (110 lb) and up to 300+ kg (660+ lb), frequently operating under vibration, dust, humidity, or chemical exposure. Manufacturers in this segment must control metallurgy, heat treatment, surface finishing, and assembly processes to maintain performance across the hinge’s life.

How do heavy duty hinges standards shape manufacturer quality?

Industry standards provide shared definitions and test methods so buyers can compare manufacturers fairly. While product categories differ by region, buyers commonly reference:

EN 1935 for single-axis hinges on doors (Europe)—focus on durability classes, load, corrosion, and safety.

ANSI/BHMA A156 series (North America)—hinge performance, dimensions, finishes, and strength requirements.

UL fire door assemblies where hinges are part of fire-rated openings; hinges may need to be listed for use with rated doors.

ISO/ASTM salt-spray (e.g., ASTM B117) for corrosion performance; hours correlate to expected environmental robustness.

A qualified manufacturer will map each hinge series to applicable standards and provide DoC (Declaration of Conformity), test reports, and, for regulated markets, listing or evaluation letters.

How should buyers evaluate a hinges factory’s materials and finishes?

Start with base metals and treatments, because they determine load capacity, wear, and corrosion:

Materials:

Stainless steel (e.g., 304/1.4301; 316/1.4401)—excellent corrosion resistance; 316 preferred for marine/chemical.

Carbon steel (e.g., Q235/A36) + heat treatment—high strength at reasonable cost; requires protective finish.

Alloy steel—used for pins/knuckles needing higher hardness and fatigue strength.

Aluminum (e.g., 6061-T6)—good for weight-sensitive doors; lower wear resistance unless hard-anodized.

Finishes:

Electro-galvanizing / zinc-nickel—economical corrosion protection; look for ≥ 240–480 h neutral salt spray.

Powder coating—adds aesthetic and environmental protection; check coating thickness (e.g., 60–100 μm).

Passivation / pickling for stainless—restores chromium oxide layer after machining/welding.

Hard anodizing (for aluminum)—improves surface hardness and wear.

Fornd’s engineering guidance: match material and finish to the worst-case environment, not the average. For example, if a hinge is installed near washdown zones, treat it as wet/chemical even if it sees only weekly cleaning.

What corrosion resistance and environmental ratings matter for heavy duty hinges?

Corrosion benchmarks often use neutral salt-spray (NSS) hours as a quick comparative indicator. Typical thresholds for industrial hinges are ≥ 240 h for mild exterior use, ≥ 480–720 h for aggressive outdoor/chemical splash, and ≥ 1,000 h for severe marine exposure when using zinc-nickel or stainless solutions. If your application includes high humidity plus temperature cycling, ask the manufacturer about cyclic corrosion tests (e.g., alternating salt fog and dry phases) and crevice corrosion considerations at knuckles and fastener interfaces.

If the hinge integrates bearings or seals, consider IP ratings for the assembly (e.g., IP54 to IP66). Remember: IP tests cover dust/water ingress resistance; they do not directly indicate corrosion capacity.

How do hinges manufacturers prove load rating, torque, and cycle life?

A credible hinges manufacturer will publish static load rating (maximum supported door weight) and dynamic performance measured as cycle life (open/close cycles) at a specified door mass and offset moment. The key is test realism:

Load model: includes door mass (kg/lb), center-of-gravity offset from the hinge axis (mm/in), and the number of hinges used (often 2–4).

Torque: derived from door weight × offset. Manufacturers should specify torque at the pin/bearing and hinge leaf fasteners.

Cycle life: validated at rated load—e.g., 200,000–1,000,000 cycles depending on class and application.

Vibration: for machinery panels, hinges may be validated to vibration spectra to check loosening and wear.

At Fornd, our rigs simulate realistic door geometry (e.g., 900 mm × 2,100 mm / 35.4 in × 82.7 in) and hinge spacing to capture actual moment arms and stress, not just simple vertical loading.

What test methods should a heavy duty hinges supplier provide?

Request a methods package with your quotation:

Dimensional inspection—leaf thickness tolerance (e.g., ±0.1 mm / ±0.004 in), pin diameter tolerance (e.g., h9), flatness/parallelism.

Metallurgy—material certificates (e.g., EN/ASTM grade), hardness of pin/knuckle (HRC/HV), weld procedure specs if applicable.

Mechanical—static load test to failure (with safety factor), cycle test with stroke angle (e.g., 0–105°), cycle speed, lubrication, and inspection intervals.

Corrosion—NSS hours to first red rust and to base metal attack; coating thickness checks (μm).

Environmental—temperature range (e.g., −40 to +80 °C / −40 to +176 °F), any IP test records.

Traceability—lot coding, PPAP/FAIR availability for OEM programs.

How do hinges manufacturer options compare on TCO and warranty?

Total cost of ownership (TCO) includes purchase price + installation + maintenance + failure risk. Two hinges with the same catalog rating can diverge on real-world TCO due to coating durability, pin wear, or hole pattern tolerance (which affects field replacement time). Warranty terms reveal confidence: look for 12–36 months coverage tied to rated duty, with exclusions clearly stated for misuse or unapproved environments.

What’s the difference between a hinges factory, manufacturer, and supplier?

Hinges factory:refers to an entity with its own production facilities (stamping/forging, CNC machining, heat treatment, surface treatment, and assembly).

Hinges manufacturer:This entity not only manufactures but also maintains R&D, testing, and quality systems (such as ISO 9001/14001), enabling engineering changes and conformance control.

Hinges supplier:This broadly defines a supplier, potentially a brand owner, trader, or distributor. Their value lies in inventory and delivery, but their quality and traceability must be verified directly back to the manufacturing source.

Fornd, as a manufacturer, provides end-to-end control from material selection and testing to assembly, and can also perform engineering modifications based on customer drawings.

How to select a heavy duty hinges manufacturer step by step?

Step 1 — Define the load case

State door mass (kg/lb), width/height (mm/in), center-of-gravity offset, and hinges count/spacing. Provide CAD or a dimensioned drawing.

Step 2 — Specify environment

Indoor vs. outdoor, chemical splash, marine air, washdown, operating temperature range, vibration.

Step 3 — Select material/finish

Choose stainless (304/316), coated carbon steel, or aluminum with suitable finish. Align with corrosion target (e.g., 480 h NSS).

Step 4 — Choose hinge type

Butt hinge, lift-off hinge, continuous/piano, concealed/torque hinge, weld-on, or heavy strap hinges—based on the door design and serviceability.

Step 5 — Define performance tests

Set minimum cycle life (e.g., ≥ 300,000 cycles @ rated load), torque margins, and any environmental/IP tests.

Step 6 — Request documentation

Ask for drawings with tolerances, test reports, certificates, and PPAP/FAIR if needed.

Step 7 — Pilot run & PPAP

Run a small batch to confirm fit/finish in your assembly; collect dimensional and performance data.

Step 8 — Finalize warranty & TCO

Align warranty to duty cycle and confirm spare policy (pins, bushings, or replacement hinges).

What specifications and drawings should be included in RFQ for heavy duty hinges?

Include a concise RFQ data set:

Bill of Requirements (BoR): Door mass & size; expected cycles/year; hinge count; max opening angle.

Dimensional drawing: Leaf length/width/thickness; knuckle diameter & pitch; hole pattern (P.C.D., hole Ø, countersink/counterbore depth); tolerances.

Material & finish: e.g., 316 SS, bead-blasted, passivated; or Q235 with Zn-Ni ≥ 12 μm + powder coat 80 μm.

Performance: Load rating target (e.g., 150 kg / 330 lb per door with 3 hinges); cycle life ≥ 500,000.

Corrosion & environment: NSS ≥ 720 h; operating −30 to +70 °C (−22 to +158 °F).

Compliance: EN/ANSI/UL applicability.

Packaging & labeling: individual bag, desiccant, lot code.

Inspection: Cpk targets for pin Ø and leaf thickness; sampling plan (e.g., ISO 2859-1).

Specifications Table(Example)

Table 1. Heavy Duty Hinge Specifications (example values)

Specification | Value | Test method / Standard |

|---|---|---|

Material / Finish | 316 stainless; passivated; Ra ≤ 1.6 μm | ASTM A240 (material), ISO 1302 (roughness) |

Dimensions & Tolerances | Leaf t = 6.0 ±0.1 mm (0.236 ±0.004 in); Pin Ø = 10 h9 | ISO 286-2 |

Corrosion resistance | ≥ 720 h NSS to first red rust | ASTM B117 |

Mechanical performance | Load rating 150 kg (330 lb) per door with 3 hinges; Angle 0–110° | Internal rig / EN 1935 guidance |

Cycle life | ≥ 500,000 cycles @ rated load | Manufacturer method (documented) |

Environmental rating | −30 to +70 °C (−22 to +158 °F); optional IP54 | IEC 60529 (IP) |

Compliance & Certification | EN 1935 class (as applicable); ANSI/BHMA reference; UL compatibility note | Standard-specific |

What does Fornd offer compared with other suppliers’ products?

We adhere to objective neutrality and verifiable indicators in our comparisons. The following table shows example levels (different series may vary):

Table 2. Comparison Matrix — Fornd vs other suppliers’ products

Criterion | Fornd (representative series) | Other suppliers’ products (typical) | What this means for buyers |

|---|---|---|---|

Salt-spray resistance (hours) | 720–1,000 h NSS (stainless or Zn-Ni) | 240–480 h NSS | Longer service in coastal/chemical atmospheres |

Operating temperature | −40 to +80 °C (−40 to +176 °F) | −20 to +60 °C (−4 to +140 °F) | Wider envelope reduces special variants |

Cycle life (times) | 300,000–1,000,000 at rated load | 100,000–300,000 | Lower maintenance and downtime |

IP rating (if sealed) | Up to IP66 for sealed designs | IP44–IP54 common | Better washdown resistance |

Torque / Tensile spec | Published torque curves & pin hardness | Single static rating only | Predictable design; easier FEA matching |

Certifications | EN/ANSI mapping; UL usage notes | General claims, limited mapping | Faster compliance review |

Lead time (typical) | 4–6 weeks standard; expedite options | 6–10 weeks | Better project agility |

Warranty terms | 24–36 months conditional | 12–18 months | Lower lifecycle risk |

TCO (maintenance frequency) | Annual inspection; 2–3 year pin/bushing check | Semi-annual recommended | Lower service overhead |

Note: The above is a general comparison example. Specific values are subject to project specifications and test reports.

What use cases fit heavy duty door hinges and how to avoid over/under-spec?

Use cases:industrial enclosures, machine guarding doors, cold-room doors, utility/plant rooms, freight lifts service doors, outdoor cabinets, marine hatches.

Avoid under-spec:don’t ignore door width and CG offset—two doors with the same weight can impose very different moments on the hinge.

Avoid over-spec:oversized stainless hinges may add cost and installation complexity; sometimes Zn-Ni carbon steel with proper sealing is sufficient.

How to install and maintain heavy duty hinges? (Checklist)

Installation checklist

Verify door mass (kg/lb) and hinge count (2/3/4) vs. rating.

Confirm hole pattern and fastener grade; torque to spec (e.g., M8 class 8.8: 25–28 N·m).

Shim for alignment; ensure parallelism between leaves within 0.3 mm (0.012 in) over leaf length.

Apply manufacturer-approved lubricant to pin/bearing if design requires.

Perform a 50–100 cycle shakedown; re-torque fasteners.

Maintenance checklist

Quarterly visual inspection in harsh environments; semi-annual in mild.

Check play at the knuckle; compare to baseline (e.g., max radial clearance +0.2 mm / 0.008 in growth).

Inspect coating for blistering/red rust; touch-up coating or replace if base metal exposed.

Replace bushings/pins per schedule (e.g., 2–3 years in high-duty cycles) or if noise/wobble exceeds limits.

RFQ/QA Templates (copy-ready)

Drawing bundle:2D PDF + STEP with GD&T; note leaf flatness ≤ 0.2 mm (0.008 in); hole position ±0.1 mm (±0.004 in).

Test plan:cycles @ load, NSS hours, environmental temperature sweep.

Quality:ISO 9001; lot traceability; FAIR for first batch; Cpk ≥ 1.33 on pin Ø.

FAQ: heavy duty door hinge manufacturers, hinges factory, hinges supplier

Q1: How many hinges should I use for a 120 kg (265 lb) door?

A1: Commonly three hinges: one at 180–200 mm (7.1–7.9 in) from the top, one from the bottom, and one centered. Validate against the manufacturer’s load chart because door width and CG offset may require a fourth hinge.

Q2: What’s the minimum salt-spray rating for outdoor coastal use?

A2: Target ≥ 720 h NSS or specify 316 stainless with passivation. For direct marine exposure, consider additional sealing and periodic washdowns.

Q3: Can I replace a carbon steel hinge with stainless without re-machining holes?

A3: Usually yes if the hole pattern matches; check leaf thickness and knuckle pitch—stainless designs can have different clearances.

Q4: How do I read EN 1935 classes?

A4: The standard assigns categories based on durability, mass, corrosion, and safety. Ask the manufacturer how your hinge’s test results map to the class relevant to your door mass and usage.

Q5: What warranty terms are reasonable for heavy duty hinges?

A5: 24–36 months conditional on rated duty and environment is typical for industrial heavy duty hinges; ensure misuse exclusions are explicit.

Fornd Heavy-Duty Door Hinges

Product | Image

| Type | Link

|

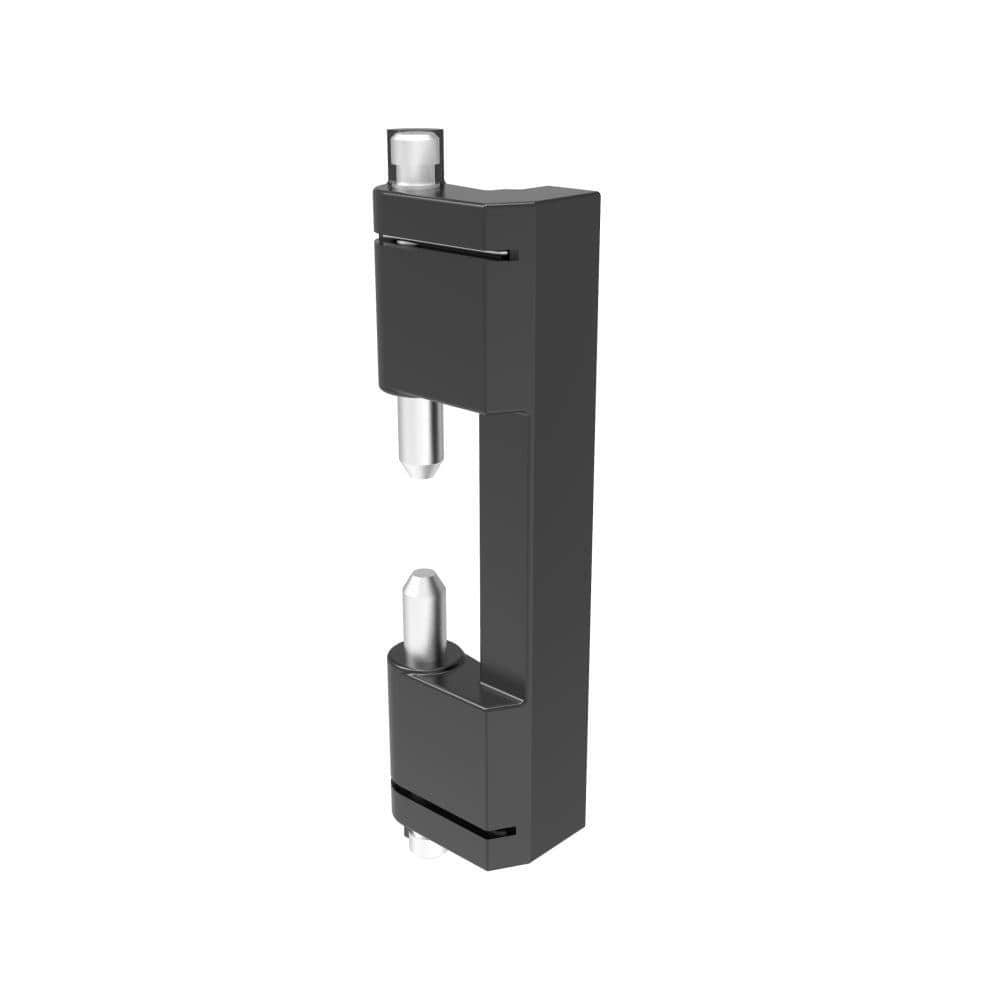

H2-2360-A4

|

| 135° hidden removable hinge, heavy duty, zinc alloy, powder coating, black

| https://fornd.com/product/corner-door-removable-hinges-h2-2360-a4

|

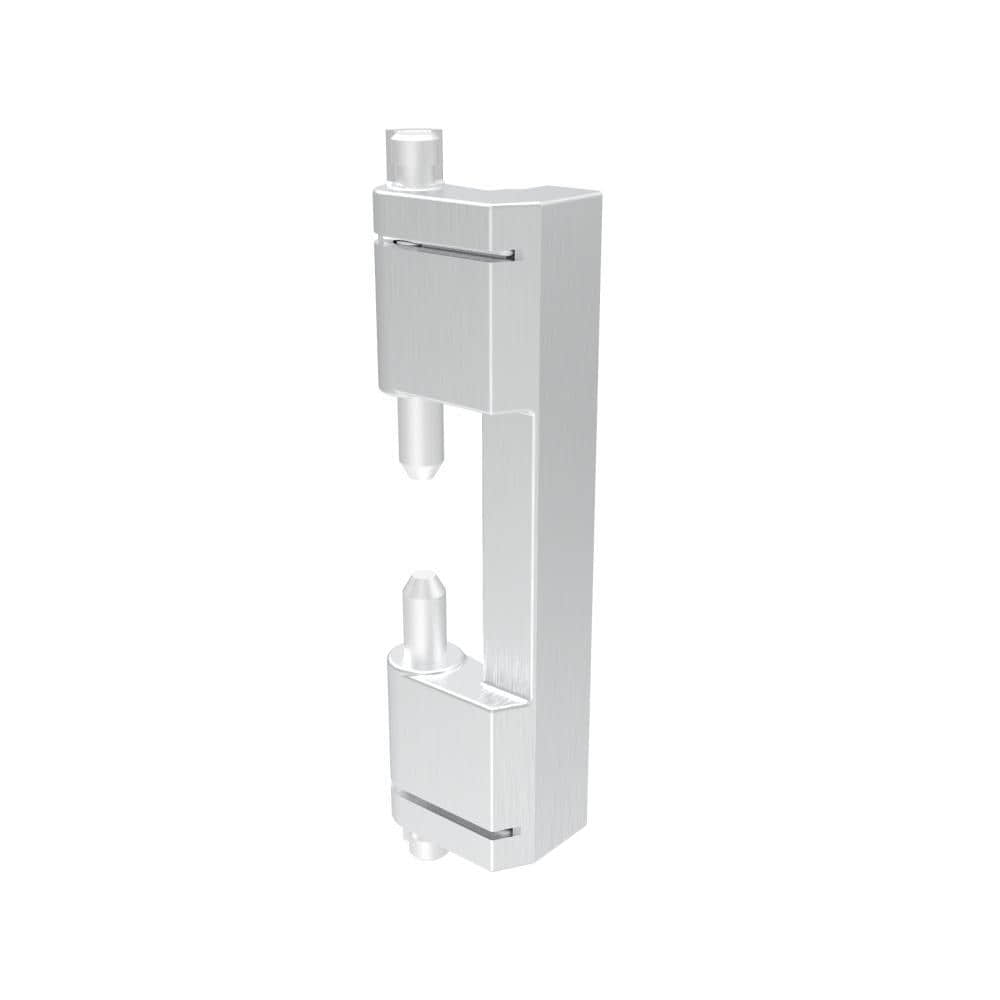

H2-2352-A1

|

| 135° recessed removable hinge, heavy duty, stainless steel, polished, bright | https://fornd.com/product/corner-door-removable-hinges-h2-2352-a1 |

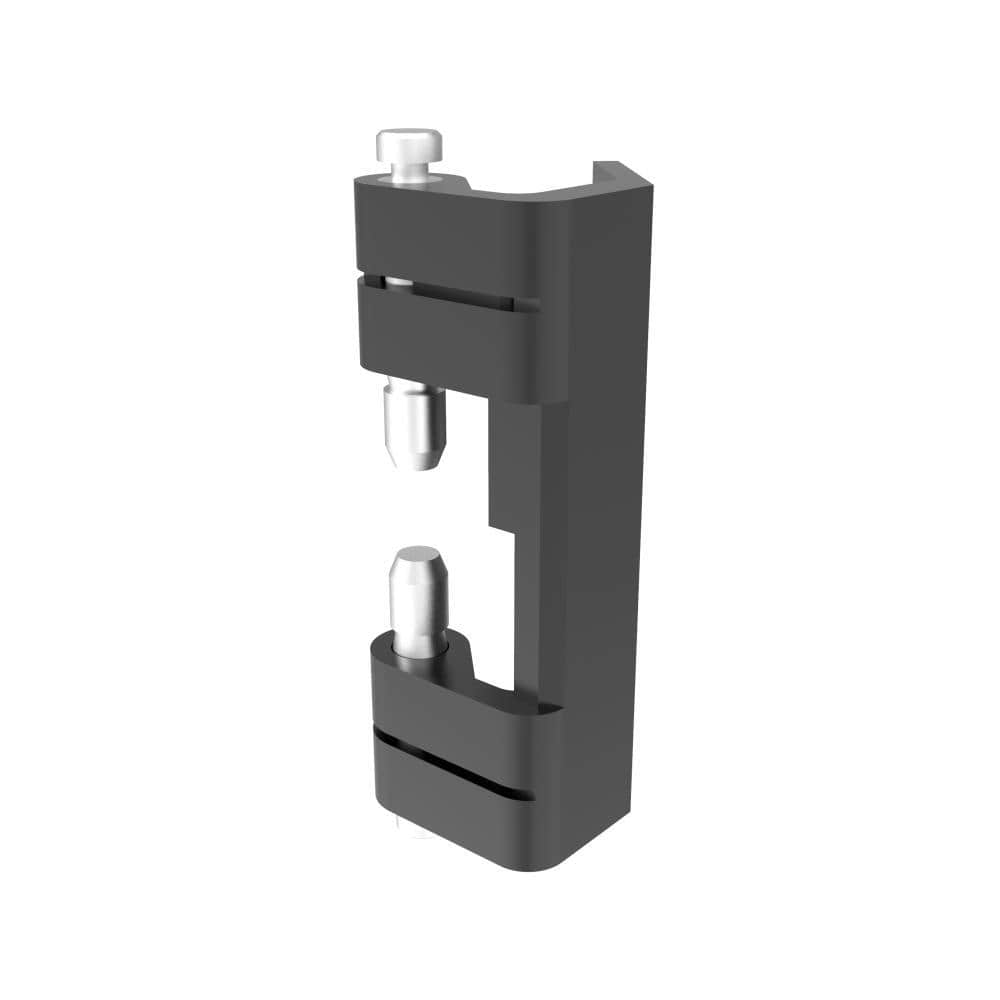

H2-2355-A4

|

| 135° hidden removable hinge, heavy duty, zinc alloy, powder coating, black | https://fornd.com/product/corner-door-removable-hinges-h2-2355-a4 |

Summary

Selecting a heavy duty door hinge manufacturer is about verifying engineering, not just browsing catalogs. By aligning materials, corrosion targets, load/torque models, and cycle life with real-world conditions—and by requesting documented test methods and certifications—buyers reduce risk and lifecycle cost. At Fornd, we combine materials engineering, realistic endurance testing, and controlled manufacturing to deliver heavy duty hinges that fit demanding environments without over-specifying. If you have a drawing or a target load case, share it with our engineering team to receive a data-driven recommendation, pilot samples, and a clear validation plan.

Next steps:Send your RFQ package (drawing + load case + environment) to Fornd engineering for a quick manufacturability review and an indicative lead time.

References:

EN 1935 — Single-axis hinges for doors

ANSI/BHMA A156 Series — Builders Hardware—Hinges

UL Fire Door Assemblies — Hardware Usage Guidance

ASTM B117 — Standard Practice for Operating Salt Spray (Fog) Apparatus

ISO 286-2 — ISO system of limits and fits

IEC 60529 — Degrees of protection (IP Code)