Heavy-duty rotary latches undergo classification and certification that adhere to rigorous industry standards to ensure, or at least strive to ensure, that these latches perform adequately in situations that are, let’s say, demanding. Now, these standards set forth minimum requirements for load capacity, cycle durability, and environmental resistance, not to mention safety compliance.

ASTM International Standards

· ASTM F3003: Standard specification for performance of mechanisms in rotary latches, establishing minimum load ratings above 2,500 lbs (1,134 kg) for heavy-duty classification.

· ASTM B117: Salt spray (fog) testing requirement of 1,000+ hours without functional degradation for corrosion resistance certification.

· ASTM E330: Performance test for structural strength under wind loading conditions (applicable for outdoor installations).

BHMA (Builders Hardware Manufacturers Association) Certifications

ANSI/BHMA A156.25: Grade 1 certification signifies the highest tier of heavy-duty architectural hardware, demanding exceptional durability and performance. To achieve this, hardware must endure a minimum of 250,000 operational cycles without failure, withstand an impact resistance of 50 ft-lbf (68 J) without deformation or functional loss, and sustain a pull strength of at least 1,800 lbs (816 kg) for 30 seconds.

Industry-Specific Standards

· SAE J839: Automotive passenger car component qualification (20G acceleration force resistance)

· MIL-DTL-38999: Military specification for harsh environment connectors and hardware

· EN 12642 XL: European standard for cargo securing devices in commercial vehicles

· ISO 27955/FMVSS 206: Automotive cargo retention component requirements

Testing Protocols for Heavy Duty Classification

Cycle Testing: Minimum 100,000 complete operational cycles without lubrication or adjustment

Load Testing: Static load capacity of 2,500+ lbs (1,134+ kg), dynamic load capacity of 1,200+ lbs (544+ kg)

It is built to survive harsh environmental conditions, to be at the peak of its performance anywhere on Earth at temperatures from -40°F to +185°F (-40°C to +85°C). Good humidity immunity, operating all the way up to 85-95% relative humidity for more than 1,000 hours, and exceptional UV exposure resistance equivalent to more than five years of constant outdoor exposure speak very loud for it to be used in demanding and varied environments.

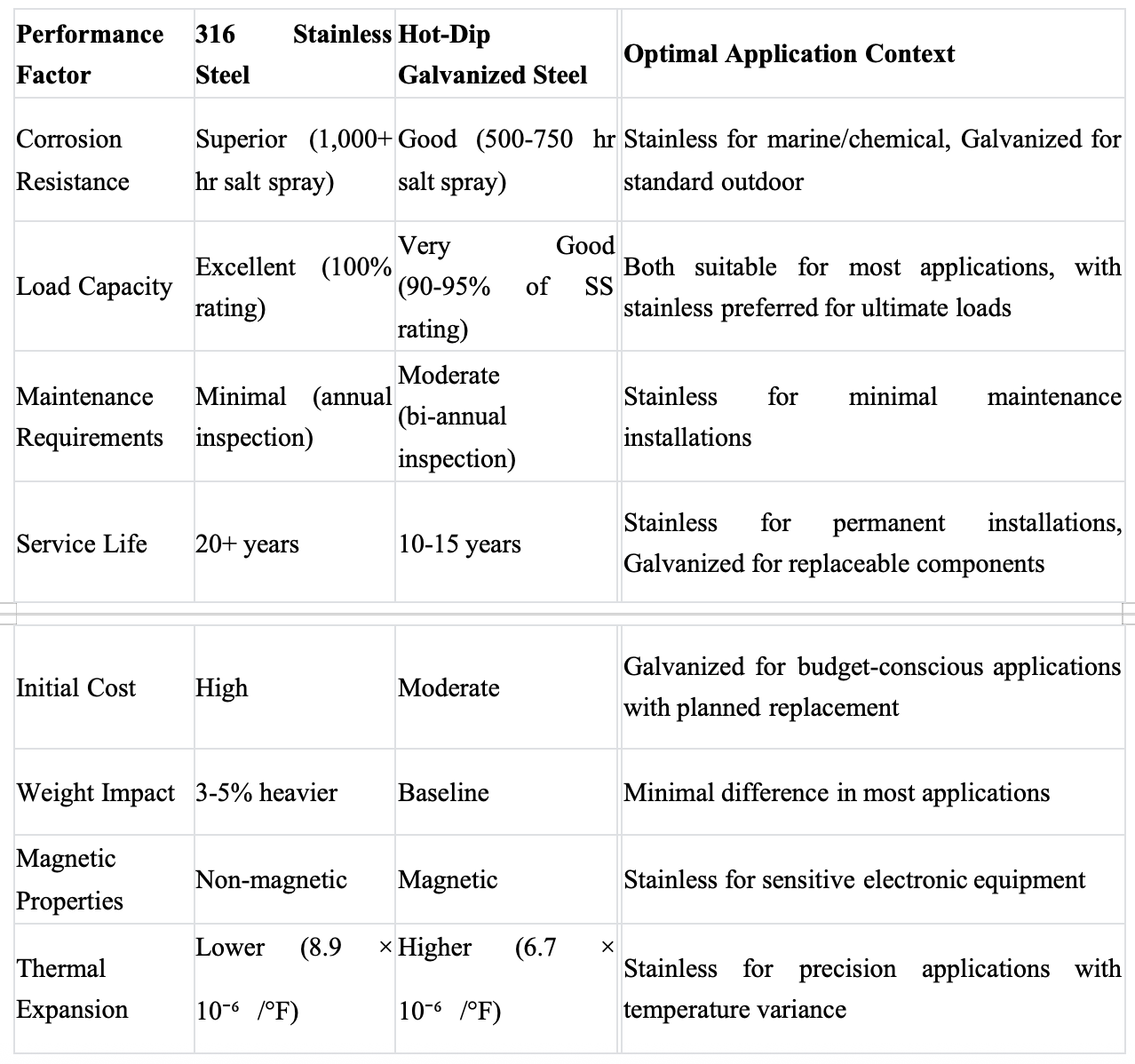

316 Stainless Steel Characteristics

Composition: Iron with 16-18% of chromium, 10-14% nickel, and 2-3% molybdenum content is ideal for use in very aggressive marine environments as it offers excellent corrosion resistance, especially against chlorides. It has very comparable strong performance in the chemical exposure field, therefore standing up to diverse and rugged industrial applications. Non-magnetic capabilities keep off ferrous attraction hence a clean environment without any chances of interfacing with sensitive equipment.

Mechanical Properties:

· Tensile Strength: 75,000 psi (517 MPa)

· Yield Strength: 30,000 psi (207 MPa)

· Hardness: 79 HRB (Rockwell B)

Temperature Performance:

· Service temperature range: -320°F to 1600°F (-196°C to 870°C)

· Maintains integrity in cryogenic applications

Weight Efficiency: Density of 0.289 lb/in³ (8.0 g/cm³)

Cost Factor: 2.5-3.5× higher than galvanized steel

Environmental Impact: Highly recyclable with 60%+ recycled content typical in manufacturing

Hot-Dip Galvanized Steel Characteristics

Composition: Base steel with zinc coating of 3.0-3.9 mils (76-99 μm). In standard atmospheric conditions, this material gives good corrosion protection primarily through sacrificial protection, where the zinc coating corrodes prior to the underlying steel. Coating life is usually defined as the time to first maintenance and is in the range of 25 to 30 years for most environments, therefore offering a long life for durability plus protection against rust.

Mechanical Properties:

· Tensile Strength: 58,000 psi (400 MPa)

· Yield Strength: 36,000 psi (248 MPa)

· Hardness: 67 HRB (Rockwell B)

Temperature Performance:

· Service temperature range: -40°F to 392°F (-40°C to 200°C)

· Zinc coating begins to degrade above 392°F (200°C)

Weight Efficiency: Density of 0.284 lb/in³ (7.85 g/cm³)

Cost Factor: Reference baseline (1.0×)

Environmental Impact: Recyclable with coating requiring separation in the recycling process

Heavy-Duty Rotary Latch Applications

Ten Major Applications of Heavy-Duty Latches

Marine Shipping Containers

Offering a solution to demanding applications in need of robust security and durability would require performance to very high levels. To be able to take that kind of treatment and stack abuse and tampering attempts to secure high-value cargo, it must resist oceanic corrosion, which means salt spray and humidity, and maintain its structural integrity. An installation that is optimum would be one where the construction is 316 stainless steel with a reinforced strike plate and a lever pad-lockable. Further to this, the system must be able to meet the load capacity requirement, which is a static load of more than 5000 lbs, and comply with ISO 1496 container hardware. Making this hardware certified to give reliable performance in such a challenging environment.

Fornd provides the shipbuilding industry with reliable and efficient hardware and positioning solutions, designed to optimize ship performance, safety, and customer business operations

Military Vehicles

To ensure reliable operation in the most challenging scenarios, this system must adhere to stringent performance requirements. It must function flawlessly across extreme environmental variations, from desert heat to arctic cold, and withstand ballistic impacts and explosive force vibrations. A critical feature is its positive locking mechanism, coupled with an emergency override capability for rapid access. The optimal configuration involves hot-dip galvanized steel enhanced with a powder coating for additional protection. The system must meet a load capacity requirement of 3,500+ lbs (1,588+ kg) with 10G acceleration resistance, and achieve MIL-STD-810H certification, guaranteeing its resilience in accordance with rigorous environmental engineering standards.

Military Vehicles

Military Vehicles

Offshore Oil Drilling Platforms

For applications exposed to the harsh realities of offshore environments, performance requirements are exceptionally demanding. The system must withstand constant exposure to seawater and petroleum products while maintaining functionality despite continuous platform vibration. Reliable operation within hazardous area classifications is also essential. An optimal configuration features 316 stainless steel combined with ATEX-certified non-sparking components. A load capacity exceeding 4,000+ lbs (1,814+ kg) with integrated vibration dampening is necessary. Crucially, the system must achieve certification under NORSOK M-501 coating system 7A/ISO 12944-9, guaranteeing its durability and reliability in these challenging conditions.

Offshore Oil Drilling Platforms

Offshore Oil Drilling Platforms

Heavy Construction Equipment

In the demanding environment of construction and heavy equipment, performance requirements are geared towards extreme resilience. The system must endure constant exposure to concrete dust, dirt, and aggressive construction chemicals, while also tolerating extreme impact and vibration during operation. Crucially, it must provide quick access for maintenance while securely protecting valuable internal components. An optimal configuration utilizes hot-dip galvanized steel, augmented with urethane vibration isolators to mitigate shock. The system must meet a load capacity requirement of 3,000+ lbs (1,361+ kg), with a robust shock loading capability. Finally, it must achieve certification under SAE J1166, ensuring compliance with standards for earth-moving machinery access systems.

Heavy Construction Equipment

Heavy Construction Equipment

Rail Transport Applications

For railroad applications, performance requirements prioritize durability and safety under severe conditions. The system must withstand continuous high-frequency vibration and maintain its integrity throughout extreme temperature variations. Critically, it must prevent accidental opening during transit, ensuring cargo and personnel safety. An optimal configuration employs hot-dip galvanized steel, enhanced with a secondary locking feature for added security. The system must meet a load capacity requirement of 2,800+ lbs (1,270+ kg) while withstanding 100G shock resistance. Certification to AAR S-5510 requirements for railroad equipment is essential, guaranteeing compliance with industry-specific standards.

Rail Transport Applications

Rail Transport Applications

Fornd has an extensive product range meant to enhance travel comfort and passenger safety while improving cabin safety and operator efficiency. The products cater to a broad spectrum of applications for the train interior and exterior. As one of the key OEMs for rolling stock and a trusted supplier for decades to Tier 1 suppliers, Fornd is intimately acquainted with the very special demands made of the rail industry.

Power Generation Facilities

In industrial settings where electromagnetic interference (EMF) and chemical exposure are prevalent, specific performance requirements are critical. The system must function reliably in high-EMF environments and withstand exposure to a range of industrial chemicals. A crucial safety feature is the provision of a positive indication of secured status, ensuring adherence to safety protocols. An optimal configuration utilizes 316 stainless steel, enhanced with a visual status indicator for quick confirmation of engagement. The system must meet a load capacity requirement of 2,500+ lbs (1,134+ kg) and incorporate electrical bonding capabilities. Certification to IEEE 1547 electrical equipment standards is essential, ensuring compliance with relevant safety and performance criteria.

Power Generation Facilities

Power Generation Facilities

Agricultural Equipment

Performance targets of applications in an agricultural setting have to take into account the general and specific requirements of fertilizers, crop protection products, dust, and off-road operation. The equipment should be made out of components that have good corrosion resistance properties to the aforestated chemicals. It should also have general resistance to dust and most static dirty conditions in control and measuring equipment and machines. The machinery should have high resistance to aggressive environmental impacts. A suitable construction for this would be hot-dip galvanized steel, which should have a mechanism that seals tight against penetration of the medium. The system should have a loading condition of more than 2,500 lbs and dust excluders easily. The system should be certified under ASABE AD26322 agricultural equipment standards.

Emergency Service Vehicles

In an emergency response vehicle, the first requirements are for the system to provide quick and safe access to equipment under extreme conditions. In practice, this would mean a quick access system and equipment retention that performs under high-speed driving and quick cornering conditions. Reliable operation is achieved in all climatic conditions. Optimum material is 316 stainless steel incorporated with an expedited emergency release feature. Two thousand five hundred pounds (1,134 kg) load capacity plus 8G acceleration resistance will also be met. The application has to be certified to NFPA 1901 automotive fire apparatus standards since this entails some very particular safety and performance standards for emergency vehicle applications.

Emergency Service Vehicles

Mining Equipment

The requirements for performance in mining and ore processing applications are super challenging due to tough conditions: the system must be very resistant to abrasive and mineral dusty environments and handle very high shock loads in minerals processing. It also needs to be extremely reliable in high humidity and potentially explosive environments. Preferably, all steelwork should be hot-dip galvanized and also coated with suitable protective coatings for increased service life. The equipment is required to take a load of not less than 3,500 lbs (1,588 kg) and also incorporate shock-absorbing capability for sustaining the effects of heavy machinery. Machinery must be supplied according to AS/NZS 4024.1 safety of machinery standards. All mining and other industrial machinery must be supplied with very stringent safety standards.

Mining Equipment

Mining Equipment

Industrial Food Processing Equipment

For food processing and pharmaceutical applications, performance requirements are centered on hygiene and resistance to rigorous cleaning. The system must meet stringent sanitation requirements for food contact applications and withstand high-pressure washdown cleaning procedures. Its most crucial aspect is to resist the action of cleaning chemicals and food acids, the optimal configuration is a 316 stainless steel with electropolished finish since it has a smooth and cleanable surface. The system must support a load capacity of 2,500+ lbs (1,134+ kg) under washdown conditions.

Certification to 3-A Sanitary Standards, NSF/ANSI 51 for food equipment materials, or equivalent standards is essential, ensuring compliance with strict hygiene and safety regulations for food and pharmaceutical processing.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.