The Material and Usage Range of Hing

Take a look at the cover of the production line or test bench: Every moving part is rotated by hinges. If the hinges are stretched, rusted or worn out, or even only the width of a single hair, the door will sag, the protective cover will fall off, the calibration will deviate, and downtime will begin. Therefore, in fields such as industrial manufacturing, building doors and Windows, and precision equipment, hinges, as key connecting components, their performance directly affects the reliability and service life of the entire system.

This guide mainly shares with you the common materials of hinges and their application scope, and recommends Fornd, a professional hinge manufacturer, which provides global customers with hinge solutions ranging from standard parts to customized ones.

What Is a Hinge?

A hinge is a mechanical device that allows two components to rotate relatively around a common axis. The structure of a hinge consists of a hinge plate, a coil tube, a hinge shaft, a bearing system and installation holes. Hinges can achieve basic rotational functions and also undertake important tasks such as load transmission, motion control and environmental sealing.

You can browse Fornd's overall introduction to hinges: https://fornd.com/blog/article/types-of-hinges-and-where-to-use-them

What Are The Common Materials For Hinges?

Each material has its own set of advantages, whether it is corrosion resistance, toughness, or simply ease of use.

Steel Hinge

Steel hinges are the main force among hinges. If something that can bear a large amount of weight is needed, steel hinges usually can handle this task. Cold-rolled steel is a very common material because it has a good, uniform thickness and a smoother surface.

Stainless Steel Hinge

If you are concerned about rusting or want durability, stainless steel hinges will take you to the next level. They are the first choice for places with high humidity or frequent weather. The polished appearance is not prone to damage. The high chromium in stainless steel can prevent rusting and loss of luster.

Brass Hinge

People like their classic appearance and the fact that they are not prone to rust. Brass does not lose much luster and does not require a lot of maintenance.

This metal is extremely soft, so in daily life, it is often seen that brass has more complex or decorative designs than some other materials. But they are not as strong as steel or stainless steel. However, if one is more concerned about the appearance of the hardware, brass is unparalleled.

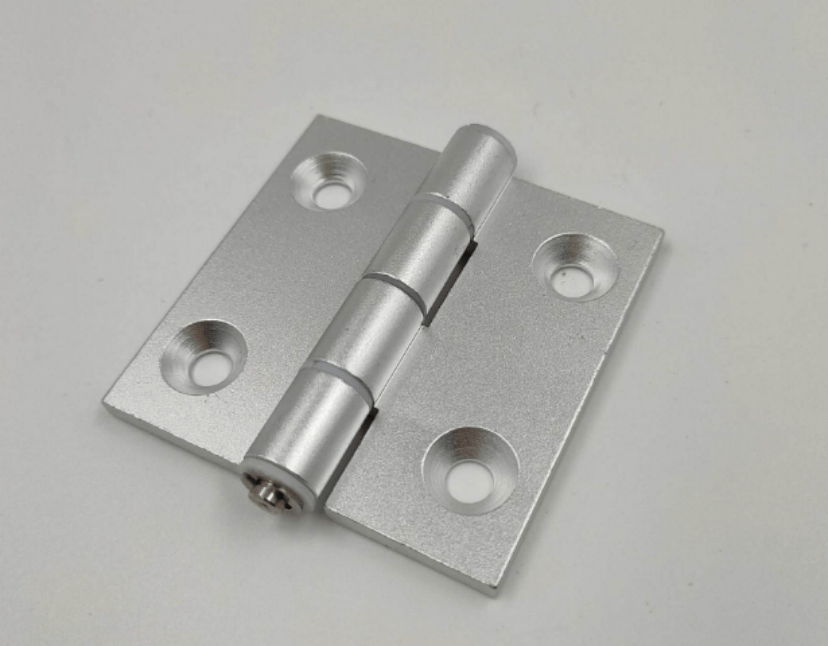

Aluminum Alloy Hinge

Aluminum alloy hinges are lightweight and rust-proof, making them a reliable choice when it is necessary to keep them light, such as for Windows, small doors or the shells of electronic devices. Aluminum is naturally antioxidant, so it usually does not require additional coatings. Besides, they are easy to process, so they come in various shapes and sizes.

Hidden Hinges and Composite Materials

If you are in pursuit of a clean and modern appearance, hidden hinges are the best choice. Commonly found in newer cabinets and flush doors, it is made of high-strength metals such as stainless steel and is sometimes used in combination with engineering plastics to achieve quieter and smoother movement.

Some more advanced hidden hinges use glass-filled nylon or similar composite materials as moving parts. These materials are extremely tough and can be bent over and over again without breaking, making them very suitable for frequently used continuous hinges or piano hinges.

Composite hinges also help hide screws and install hardware. If designed properly, these materials can even protect the internal structure from dust and wear.

Welded Hinges and Heavy-Duty Hinges

For gates, industrial doors or heavy machinery, welding and heavy-duty hinges are almost the only way out. They are made of materials such as cold-rolled or stainless steel and can withstand heavy weights without loosening.

Good coatings (such as galvanizing or powder coating) can prevent these hinges from rusting, which is particularly important for outdoor use. In addition, heavy-duty hinges are usually designed to be easy to adjust and maintain, so you can keep them working smoothly even if they are hit.

Fornd provide hinge material is complete, you can custom selection: https://fornd.com/category/hinges

In What Fields are Hinges Applied?

Nowadays, the application fields of hinges are very diverse.

The Field of Industrial Manufacturing

Whether it is control cabinets, distribution boxes and other equipment cabinets, or inspection doors of heavy machinery, or high-frequency operation production lines, they all require hinges with specific performance to ensure the stable operation of the equipment.

Application of Building Doors and Windows

The construction industry has equally strict requirements for hinges. Fireproof doors and anti-theft doors in commercial fields require special hinges to ensure safety performance. Interior doors should not only pursue a quiet effect but also take into account their aesthetic appeal. Special doors and windows, such as explosion-proof doors and radiation protection doors, put forward higher technical requirements for hinges.

Transportation Equipment

The performance requirements for hinges in the transportation sector are particularly unique. Rail transit requires hinges that can withstand continuous vibration and fatigue tests. Under the trend of lightweighting in the automotive industry, hinges still need to maintain sufficient strength and so on...

And Fornd series is suitable for high speed rail car coat hook and a variety of hinge, to any fixed screen, handrail, the Angle head and drop-down desktop, improve the convenience and security of the user: https://fornd.com/solution/6

Precision Equipment

The application of hinges is more precise. Medical equipment requires that the hinge materials meet the special requirements of a sterile environment. The hinges of experimental instruments need to have characteristics such as anti-magnetic and anti-static. The aerospace field has set the highest standards for the reliability of hinges in extreme environments.

How To Install Hinges?

Fitting a hinge is mostly about patience, sharp pencils, and letting the screws do the work—not your shoulder.

• Mark the spot: Stand the door on its edge and nick the frame with a pencil where you want the hinge knuckle to land. Do the same on the door itself. A square keeps the lines plumb so the barrel won’t bind later.

• Start the screws: Drill a pilot bit one size smaller than the screw shank, right on your pencil tick. The hole only needs to go as deep as the screw length; it stops the wood from splitting and pulls the hinge leaf dead flat.

• Hang the first leaf: Lay the leaf in place, drive one screw until it’s snug, then check the line again. If the leaf moved, back the screw out a quarter-turn and tap the hinge with a block of scrap until it lines up. Add the rest of the screws.

• Bring the two halves together: With the first leaf tight, swing the second leaf over and mark its holes on the opposite surface. Drill pilots, start one screw, test the swing. If the door rubs, loosen that single screw, nudge the leaf a hair, and drive it home again.

• Final swing test: Open and close the door slowly. You should hear nothing but the click of the latch. If there’s a squeak, back out one screw, touch the hole with a candle stub for dry lubrication, and drive it back in. Done.

How To Solve Common Hinge Problems And Part Failures?

During long-term use, hinges will encounter problems to a greater or lesser extent. Understanding common problems and their causes can help eliminate faults and find effective solutions.

• Squeaking: The common squeaking sound problem of hinges is caused by insufficient lubrication or friction due to rust. Applying silicone spray to the pins and steering knuckles usually solves this problem.

• Loose hinges: The screws that fix the hinge leaves lose their sealing property, causing the door to sag and close improperly. The first step involves tightening the screws. Peeling screw holes require longer or thicker screws, as well as wood glue and toothpicks to fill the holes or slightly reposition the hinges.

• Rust and corrosion: Hinges made of standard steel will rust and corrode when in contact with moisture. A wire brush can be used to remove light rust, and applying an anti-rust agent helps protect the surface. The most effective remedy for severe rust is to replace the hinges with stainless steel or other corrosion-resistant materials.

• Damaged or bent parts: When hinge components (such as pins and leaves) are subjected to excessive force and wear, they will be damaged. In this case, the entire hinge needs to be replaced. Check the maximum load capacity of the hinge to avoid these types of faults.

About Fornd

Fornd offers a variety of hinges in different types and materials, which can be adapted to a wide range of application scenarios and scopes. With a complete product line and professional manufacturing techniques, we are committed to precisely matching hardware accessories for customers to achieve efficient installation and long-term reliable use.

The complete product technology database, online selection calculation tools, and engineering application case references can be obtained by visiting Fornd 's official website https://fornd.com/. If you need professional technical support, please send an email to info@fornd.com. We will provide you with free sample testing, personalized solution design and installation guidance services, etc.

FAQs

What is a hinge and how does it work?

What is a hinge? As a mechanical device, a hinge is a mechanical apparatus that connects two objects and allows them to rotate relatively. It has certain flexibility and durability.

Can aluminum hinges carry heavy doors?

Only if the load is light. For doors over 40 kg switch to steel or stainless versions to avoid sagging.

Are brass hinges purely decorative?

They add vintage appeal and resist corrosion, yet their lower strength limits them to interior or low-load doors.