The Anatomy of a Lock and How Locks Work

Essential parts of industrial enclosures, locks control access and guarantee the security of telecom, electrical, and transportation equipment. Knowing how a lock operates—inside and outside—helps facility managers and engineers decide which replacement, maintenance, or selection is best. Leading supplier of industrial locking systems, Fornd provides a large selection of lock types catered to specific operating requirements. This book dissects the architecture of a lock and clarifies the mechanics of some of the most often used systems.

Basic Anatomy of a Lock

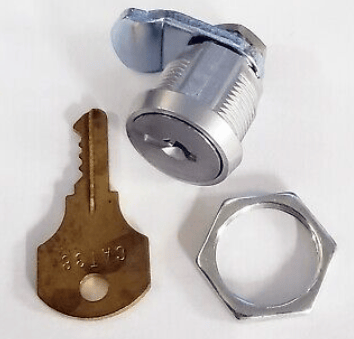

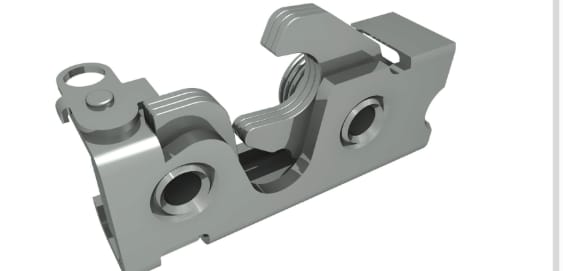

Shelter (Shell)

Within a lock, the housing serves as the structural outer shell shielding and supporting mechanism for every moving component. Using either stainless steel housings or precision-cast zinc alloy ensures durability against mechanical stress, corrosion, and outside force in outdoor cabinets or industrial enclosures.

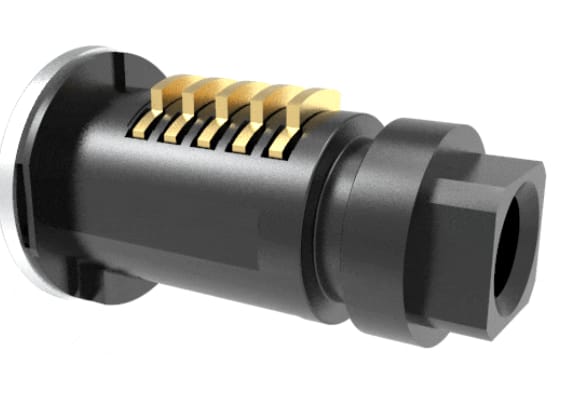

Plug (Core)

The plug is the rotating inner cylinder in which the key is inserted. The right key will move naturally to operate the locking mechanism. High tolerances machined on Fornd's plugs provide consistent operation and fit with both master key and keyed-alike systems.

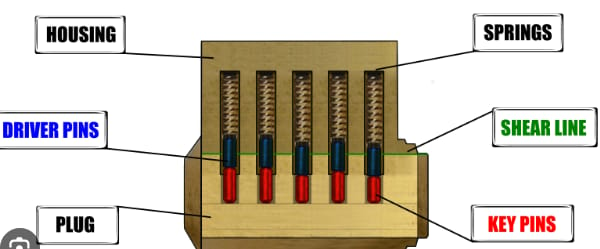

Pines and springs

Unless precisely aligned, varying-length key pins and spring-loaded driver pins in pin tumbler systems block the plug from turning. Over long cycles, anti-pick features, stainless-steel springs, and hardened pins help fornd cylinders resist damage and maintain integrity.

Driver Pins

Drivers pins pass tension between the springs and the key pins. Their relevance lies in properly orienting the shear line. Fornd uses heat-treated steel drivers in its high-security cylinders together with anti-bump geometries to reduce handling vulnerabilities.

Shear Line

The exact gap between the plug and housing where aligned pins allow rotation is the shear line. Bad alignment lets the lock jam. Tight machining tolerances from Fornd guarantee consistent and repeatable shear lines even after long-term usage.

Sidebar

When discs or pins are not in the correct position, a sidebar—a mausa secondary locking element—engages. It gives more defense against lock-picking. Fornd makes use of this function in disc tumblers and dimple key models to raise forced entry resistance.

Disc Tumbler Locks, or Disc Stack

Some locks use rotating discs lined by a flat key instead of pins. Once in line, a sidebar closes. In dusty, wet, or vibration-sensitive environments like field cabinets or telecom enclosures, Fornd's disc cylinders shine.

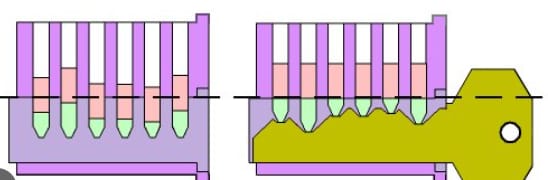

How Locks Work

Although most locks have the same basic function—securing access—they run under different mechanical systems. The key in a basic pin tumbler system raises every pin stack to the exact height required to produce a clean shear line. The plug moves the cam or tailpiece to disengage the latch once aligned.

Rotating discs in disc tumbler locks must align their side slots such that a sidebar can retract and plug rotation can result. Ideal for demanding environments, these systems are more dirt- and vibration-tolerant.

Rotary latches capture a striker by mechanical pawl that rotates inward and holds it tightly until released by a cable, push-button, or handle. This internal geometry allows small, shock-resistant locks in machinery housings and vehicle compartments.

Electronic locks run in place of conventional keys using sensors or programmed logic. Advanced control in secure installations comes from a signal from a keypad, RFID, or network controller releasing the latch from a motor or solenoid.

Lock Design Variations for Performance Environments

System of Modular Locking

Fast replacement of cores is made possible by modular locks without compromising the whole housing. Ideal for telecom panels or fleet maintenance where security levels or key access may vary over time, Fornd supports field re-coring via quick-change designs.

Shock and Vibration Control

Industrial locks have to withstand vehicle or machinery vibrations. In high-movement environments, Fornd provides vibration-resistant cylinders and rotary latches with spring-loaded cams and anti-rattle components to prevent loosening or inadvertent disengagement.

Tool-Defined Access

Keyless but limited access is absolutely vital in public-facing enclosures. Using triangle, double-bit, or Allen-style heads, Fornd's tool-operated locks guarantee only authorised staff with the right tools can open equipment panels or test stations.

Integration of Surface Design

Flush-mount locks lower snag hazards and remove protrusions. By designing recessed cylinders and integrated cam systems that sit level with enclosures, Fornd improves both safety and aesthetics in cleanrooms, car interiors, or small projects.

Fornd's Material and Design Innovations

Fornd selects materials based on planned use and location. Stainless steel of marine grade handles the corrosion and moisture of outdoor designs. Zinc alloy indoor panels provide consistent strength at a reasonable price. For sites calling for lightweight materials or insulation, Fornd develops reinforced polymers. Under demanding conditions, surface finishes including powder coating and nickel plating increase wear resistance and extend service life.

About Fornd

It offers industrial-grade locks, hinges, latches, and enclosure hardware in trust. From public infrastructure, power cabinets, telecom shelters, industrial equipment, drives our lock cylinders and rotaries for a high-duty use. By means of flexible customizing, fast prototyping, and sample support, Fornd guarantees OEMs and integers consistent enclosure access. Visit fornd.com to find further information.