Choosing the right cylinder is very important for industrial uses. A cylinder is the main part of a lock. It is the part where you put the key. These locks are used on many things, like cabinets, telecom equipment, cars, and other big machines. A good lock keeps things safe. A bad lock can cause problems. Fornd is a company in China that makes excellent industrial locks, bolts, hinges, and handles. They help industries find the best parts for their needs. This guide will help you understand how to pick the right cylinder for your job.

Reading this article, you will learn about the different kinds of cylinders and the materials they are made from. This helps you choose a lock that will last a long time and explains how to measure for a new cylinder so it fits perfectly. It also talks about security. This is important, so you can protect your equipment. If you work in an industry that uses cabinets, special vehicles, or any kind of industrial equipment, this information will be very useful. It will help you make a smart choice and avoid problems later.

Which Cylinder Types Are Frequently Used?

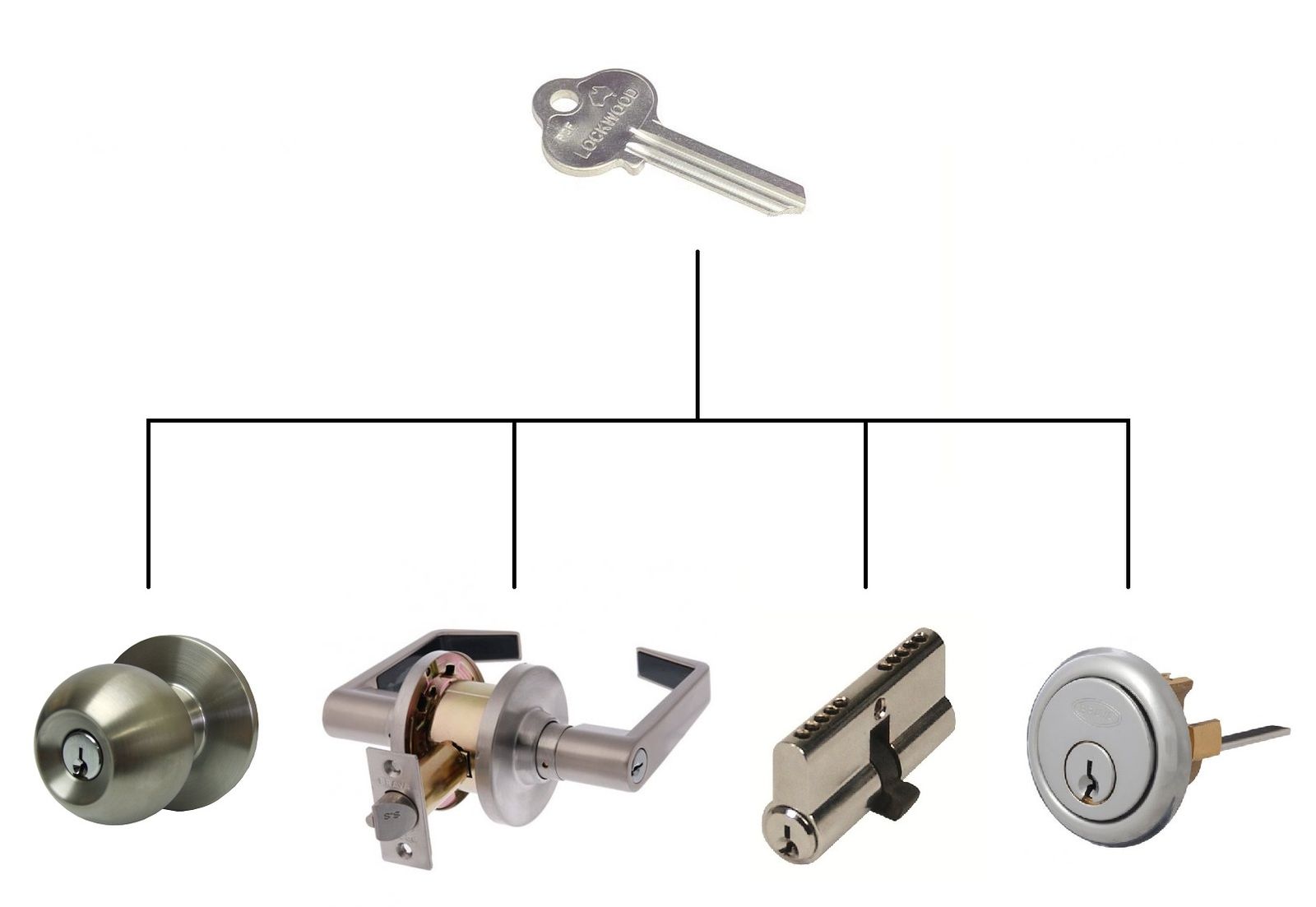

First, you need to know what kind of cylinder you need. There are many types for industrial uses.

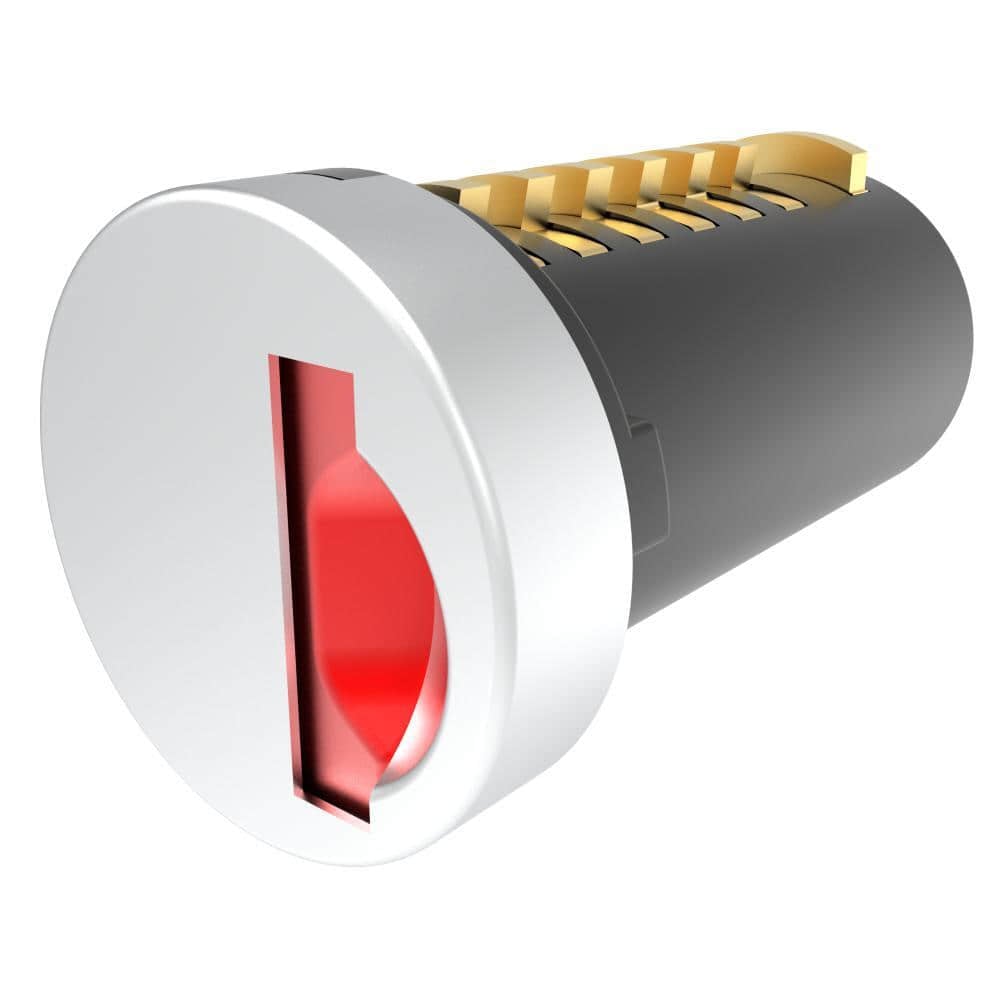

Cam Lock

A very common type is the cam lock. A cam lock has a small metal plate, the cam, at the back. When you turn the key, the cam turns and locks or unlocks a door or panel. These are good for metal furniture, electrical boxes, and display cases.

Disc Tumbler Lock

Another type is the disc tumbler lock. These locks use small, flat discs inside. The correct key lines up the discs so the lock can turn. They are strong and work well in different weather. This makes them good for outdoor cabinets or storage lockers.

Radial Pin Tumbler (RPT) Lock

Radial pin tumbler (RPT) locks offer more security. They use pins arranged in a circle. You need a special tube-shaped key to open them. These are harder for people to pick. So, they are used for things like vending machines or equipment that needs extra protection.

Multi-Point Locking Systems

For the highest security, there are multi-point locking systems. These systems lock a door at several points all at once. A single cylinder controls all the locking points. Fornd makes advanced multi-point locking systems that are great for large doors on industrial buildings or secure data centers. You need to think about what you are locking. Then you can choose the right type of cylinder for the job.

What Material is Best For Your Application?

Next, think about the material of the cylinder. The material affects how strong the lock is and how long it lasts. At Fornd, we often make cylinders using five types of materials: zinc alloy, stainless steel, brass, PA66+30%GF, and steel. Here is a table of each material's features.

Material | Features |

Stainless Steel | Highly durable, rust-resistant; ideal for outdoor or high-moisture environments. |

Brass | Corrosion-resistant, durable, easy to machine; commonly used for internal lock components. |

PA66+30%GF | Lightweight, rust-proof, and does not conduct electricity. |

Zinc Alloy | Lightweight, low-cost, moldable; suitable for light-duty indoor use. |

Steel | Very strong, often hardened; used for lock bodies; provides high resistance to drilling and physical attack. |

How Do You Get The Right Size?

Getting the right size is very important for the lock to work well. If the cylinder is the wrong size, it will not fit or it will not be secure. You must take precise measurements. Here are a few things to consider when you make the decision.

Barrel Length

The most important measurement is the barrel length, also called the housing height. This is the length of the cylinder part that goes through the door or panel. To find this length, you need to measure the thickness of your door or panel. The cylinder needs to be long enough to go through the hole and have enough space for the nut on the back to hold it tight.

The Diameter Of The Hole

The diameter of the hole where the lock will be installed must also be measured. Most industrial panels have standard hole sizes, but it is always good to check. The cylinder must fit snugly in the hole. Some holes are round, and some have flat sides, called a "double-D" shape, which helps stop the lock from spinning.

Cam Size & Shape

For cam locks, you also need to choose the right cam size and shape. The cam is the arm that does the locking. Its length is measured from the center of the cylinder to the tip of the cam. You need to know the distance from the front of the door to the point where the cam will touch the frame. This ensures the door will be held shut tightly.

What Level Of Security Is Necessary?

Not all applications need the same amount of protection, so you must think about the level of security you need.

Keyed Alike

Think about who needs to open the lock. You can choose different keying options. "Keyed alike" means one key can open a whole set of locks. This is useful when one person needs to access many cabinets. While "Keyed differently" means every lock has its own unique key. This is for situations where different people should only access specific things.

Anti-pick and Anti-drill

There are security features that stop people from breaking the lock. Anti-pick features use special pins that make it hard for someone to use tools to open the lock. Anti-drill plates are made of hardened steel. They protect the cylinder from being destroyed by a drill.

How To Choose Lock Cylinders For Different Applications?

Lock cylinders are also common in offices and stores. They secure documents in filing cabinets. They protect valuable items in glass display cases. They are also used on personal lockers in schools or gyms. These locks provide basic security and keep personal items safe.

Cabinets

Lock cylinders are very important for industrial and electrical cabinets. These cabinets often hold sensitive electronics or dangerous equipment. A good lock cylinder keeps unauthorized people out. They provide security for these important systems like server racks, electrical control panels, and telecommunication boxes. For example, a simple and reliable cabinet lock cylinder like the Fornd 9345 Cabinet lock lock core is used in many of these cabinets to keep them secure.

Vehicles

You can also find lock cylinders on vehicles. They are not just for car doors. They are used to secure items on the outside of a car or truck. For example, truck toolboxes need strong locks to protect expensive tools. Car roof racks also use special lock cylinders. These locks stop people from stealing the rack or the items attached to it, like skis or bikes. The Fornd 9341 Car luggage rack lock cylinder is a good example of a lock made just for this purpose.

Outdoor

Some lock cylinders must work outside. They are exposed to rain, snow, and dust. So they need to be made from special materials. These locks protect public utility boxes, outdoor payment kiosks, and machinery. The material must resist rust and corrosion. Stainless steel is a great choice for this. A lock like the Fornd 9302 Cabinet lock is perfect for these harsh environments because it will not rust and will keep working for a long time.

Conclusion

Picking the right cylinder is important. It affects how safe and how well your industrial equipment works. Each step in choosing the right cylinder is important to find the perfect fit. Making the right choice keeps your equipment safe and working well.

Fornd understands this. As a professional manufacturer of industrial locks, bolts, hinges, and handles, we offer a wide range of high-quality products for many industries. If you have any questions or need a special solution for your business, do not wait. Contact Fornd today at https://fornd.com/contact. Our team is ready to help you with advice, quotes, and samples, so you get what you need.

FAQ

What is a cam lock and where can it be used?

A cam lock has a small arm (the cam) that turns to lock a door or panel. They are very common for industrial cabinets, electrical boxes, and vehicle storage compartments.

Can I get help if I am not sure which cylinder to choose?

Yes. Professional suppliers like Fornd have expert teams that can help you. They can give you advice and guide you to the perfect lock solution for your specific industry needs.

What is the most important measurement when choosing a cylinder?

The barrel length is most important. It must match the thickness of your door or panel, so the lock fits correctly.