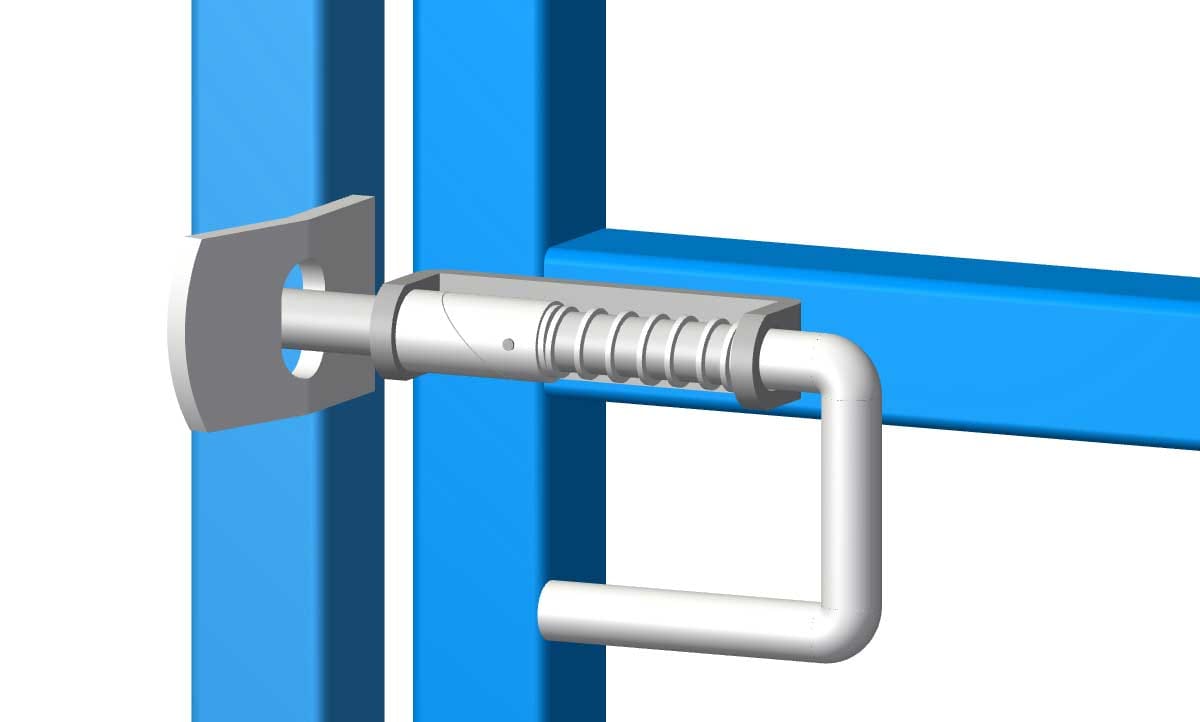

Slam latches, or push-to-close latches fasten doors, panels, or covers very quickly and securely. A bolt or pin, which is spring-loaded, is integral to the design of these latches. When the door is slammed, the bolt comes into direct contact with a matching catch or striker plate screwed onto the frame. It is this impact that compresses an internal spring. The bolt is held back until it can slide over the striking surface. Having passed the first step, that is, aligning with an opening or recess in the striker plate, the bolt flies in with stored spring energy into this space, making a latching action that is automatic and secure, and there is no need for manual operation.

For the best performance, buy slam latches from top manufacturers like Fornd. They lead in industrial access hardware and offer various slam latches and parts. More information can be found here:

After you choose a good supplier, you must install the slam latch right. This guide will help you with the installation.

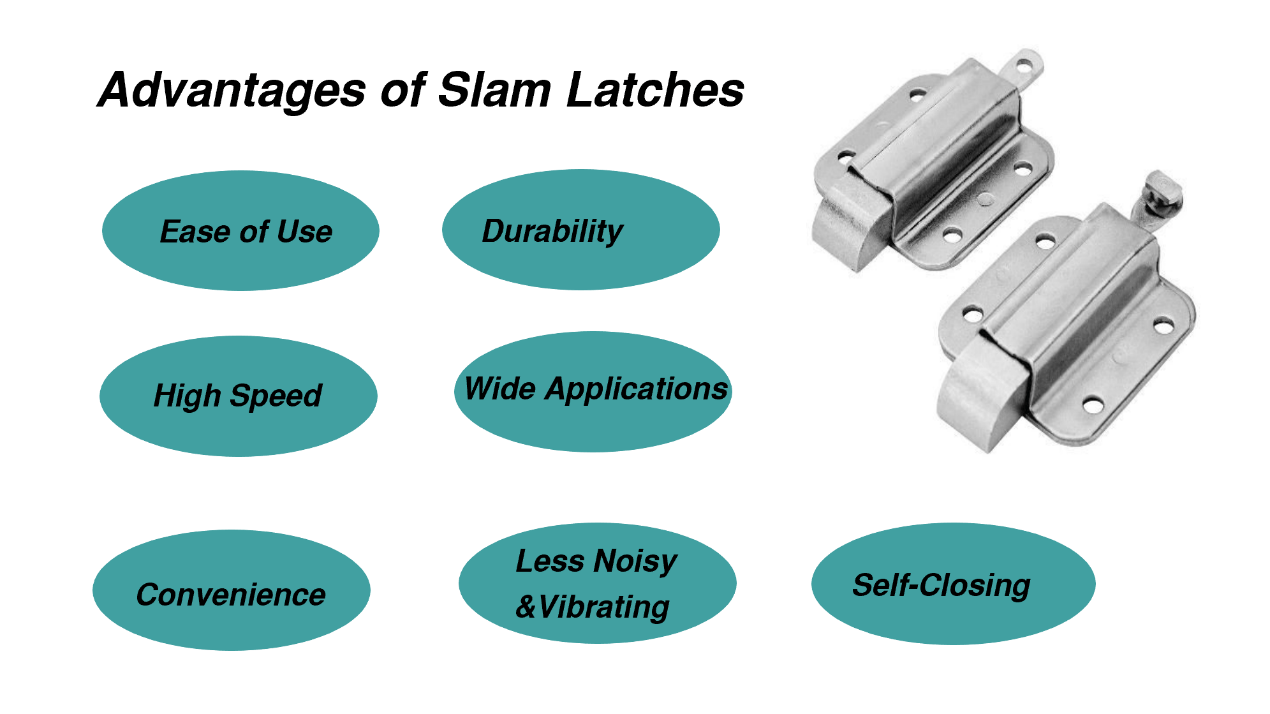

Advantages of Slam Latches:

Ease of Use: With a simple push-to-close operation, then it eliminates complicated locking mechanisms, making slam latches accessible for users of all ages. Its intuitive design requires little training, cutting the time for new users, which is most applicable in facilities or environments wherein there are multiple users.

Speed: Allows rapid closing and securing of doors or cabinets, which saves a lot of time on securing enclosures. This is most ideal for time-critical areas such as healthcare facilities, commercial kitchens, or industrial settings, where quick access and secure closure will have an impact on workflow productivity as well as on safety protocols.

Convenience: There is no manual effort required to open it, so the hands of the users are free to carry their items and do something else simultaneously. This feature becomes very useful when a user is carrying materials; he has to carry out multiple tasks at the same time or in an environment where proper contamination control is being maintained and the minimization of touchpoints is necessary.

Durability: Mostly meant for regular and intense use, with strong materials and reinforced parts that can bear thousands of operation cycles. The spring-loaded mechanisms are made to keep tension for a long time, and many types have a finish that keeps away rust to preserve function in harsh environments, leading to a longer life of use compared to common latches.

Wide Applications: It can apply to many applications and how it mounts, ranging from industrial cabinets to residential furniture. Coming in many sizes, materials, and designs to cover a range of door thicknesses, weights it can support, and different aesthetic requirements. Most slam latches can be mounted in the vertical or horizontal direction and adjust to both flush and overlay doors, making them ideal for a wide range of projects in many different types of industries.

Less Noisy and Vibrating: Some styles aid cut down on rattling through parts made with precision and included dampening aspects. Better versions include rubber or silicone cushions that soak up closing shock forces, stopping the spread of vibrations all over and making a quieter working place. This sound decrease is very useful in places where noise matters, like libraries, hospitals, or offices.

Self-Closing: The door automatically closes itself, thus making sure that enclosures will not stay half-opened because of any neglect on the part of the user. It hence adds security by not letting unauthorized people enter inside, preserves energy by retaining the climate control, and helps keep the safety norms in places where the rule is to keep the doors closed when not in use. Self-closing also helps increase the life of the adjacent equipment since it will keep it safe from environmental impurities by not letting them enter, as well as from changes in temperature.

How to Install a Slam Latch?

Installing a slam latch properly ensures reliable operation and longevity. Here's a comprehensive guide to help you through the process:

Materials & Tools Needed

· Slam latch kit (latch mechanism, strike plate, and mounting hardware)

· Electric drill with appropriate drill bits

· Screwdriver (Phillips or flathead, depending on hardware)

· Pencil or marker

· Measuring tape or ruler

· Level

· Center punch (optional)

· File (optional)

· Safety glasses

Step-by-Step Installation Guide

Step 1: Preparation

Pre-installation examination to determine the position of the latch for optimal closing of the door and alignment with the frame and also prepare the surface where the latch is to be installed.

Step 2: Marking the Position

Shut the door to show the true striking point of the bolt on the frame, then measure and mark the middle point for the latch on the edge, using a level to make all alignment marks straight.

Step 3: Drilling the Latch Hole

Choose a drill bit that matches the diameter of your latch mechanism, put on safety glasses, drill a pilot hole first and then gradually increase the size to the size needed, and drill into the edge of the door so that it is perpendicular.

Step 4: Installing the Latch Mechanism

Install the latch body into the drilled hole, flush the faceplate with the door edge, mark screw holes through it, drill pilot holes for screws, and then secure it by screwing in the screws provided ensuring a flush fit.

Shut the door until it hits the frame, note where the bolt touches, draw the shape of the plate, cut a small hollow for the plate if needed, make the hole for the bolt, and then put on the plate using the screws given.

Step 5: Installing the Strike Plate

Close the door until the latch contacts the frame, mark the impact position of the latch bolt, trace the outline of the strike plate at this point, chisel out a shallow recess for the strike plate if needed, drill the bolt hole, and then mount the strike plate with the provided screws.

Step 6: Testing and Adjustments

After installation, thoroughly test the slam latch by opening and closing the door multiple times, ensuring the latch engages smoothly and requires minimal force. Listen carefully to the distinct "click" sound that indicates proper engagement. If the latch doesn't engage cleanly, make necessary adjustments to the strike plate's position. Should you notice any catching or resistance during operation, carefully file down any rough edges on the latch or strike plate to ensure a seamless and reliable closing action.

Step 7: Final Check

To achieve the right functioning life, carefully screw all screws of the door mechanism. Then, firmly check that the latch engages securely and always with each try to close the door. Confirm that the door opens easily and without much effort when using the given handle or knob. Finally, check the maker's guide and put a little right lubricant on any suggested moving part to keep it working well.

Maintenance Tips of Slam Latches

Regular Cleaning: Dust, dirt, and debris can accumulate within the latch mechanism, hindering smooth operation. Periodically wipe down the exterior of the latch and the striker plate with a clean, dry cloth. For more stubborn buildup, a slightly damp cloth can be used, ensuring it's dried thoroughly afterward.

Lubrication: Friction can cause wear as well as stiffness in the operation of a moving part. Apply a small amount of suitable oil to the bolt of the lock, the points at which it pivots, and all other parts that move. Use a silicone spray or dry graphite type of lubricant since these will not hold dust as much as the oily ones. Follow the suggestions of the manufacturer for the ideal type of lubricant for your particular latch. Apply every few months, or when it seems to be needed if it is stiff or noisy.

Check and Tighten Screws: Because of the vibrations and all, the mounting screws on both the latch and the striker plate can become loose over time. It is necessary to check these screws often and tighten them as required so that the latch will stay put and stay aligned properly. If the screws are loose, then it will not align properly and will not engage as required.

Inspect for Wear and Damage: Check the latch body, bolt, spring, and striker plate from time to time for wearing, corroding, or damage. Check for bent or broken parts, excessive rust, or cracks, in the bolt. If any of these is noted, damaged parts should be replaced, or the entire latch assembly if needed to retain security and operability.

Ensure Proper Alignment: Proper alignment of latch bolt and striker plate for reliable operation. Shift in door or frame alignment may cause misalignment over a period. Check on regular basis that latch bolt smoothly and without any hindrance enters striker plate. If it does not, then remove mounting screws of striker plate, reposition it as needed, and then securely tighten screws.

Address Stiffness or Binding: In case you notice that the latch has become stiff or sticks during operations if it binds, do not force it open. First, clean the mechanism and then lubricate it. Check whether some dirt has caused the stiffness, and if the latch is still binding, inspect it for any obstructions or damage that may have occurred. Trying to force open a stiff latch can result in its breaking.

Follow Manufacturer's Instructions: Always refer to the specific maintenance guidelines provided by the slam latch manufacturer. They may have recommendations tailored to the materials and design of their product.

Regular Testing: Periodically open and close the door or panel to ensure the slam latch engages and releases smoothly and securely. This regular testing can help identify potential issues before they become major problems.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.