For the locking of significant industrial enclosures, the most suitable lock type depends on the frequency of access, environmental exposure, and required security level. The expert recommends a compression latch for sealed or high-vibration enclosures, a multi-point swing handle for large doors requiring even pressure, and a heavy-duty cam lock for general-purpose access control.

This article is a step-by-step guide to walk you through these decisions. We'll explore real lock mechanisms, material science, and industry standards (IP/NEMA). You'll find comparison charts, installation considerations like grip range, and expert recommendations based on our experience as a manufacturer to allow you to select a lock that offers both security and operational integrity.

Why Does the Wrong Cabinet Lock Put Safety, Compliance, and Performance at Risk?

Choosing an industrial cabinet lock is more than just about stopping people from getting in. It's a key decision that affects how well your equipment works, keeps people safe, and follows the rules.

A wrong lock can cause major problems. For example, if a lock doesn't seal properly, dust can get into an electrical cabinet and cause a fire. Similarly, if a lock doesn't create a tight seal, water can get in and damage sensitive equipment, like 5G technology.

The right lock also helps things run smoothly. It lets maintenance workers get in easily when they need to, but keeps others out.

Ultimately, the lock is a vital part of the entire cabinet's design. It affects everything from preventing rattles in vehicles to keeping things sterile in medical cabinets.

Which Lock Types Match Which Industrial Cabinets?

There is no single "best" lock because different jobs need different locks. The right choice always depends on what you are using it for. A lock for an indoor server room will be different from a lock for an outdoor utility box.

You should consider:

Does it need to keep out dust and water? Does it need to resist shaking and vibration? How often will it be opened? How secure does it need to be? Knowing what you need is the first step to choosing the right lock.

Why Are Cam Locks the Fast, Cheap, All-Round Choice?

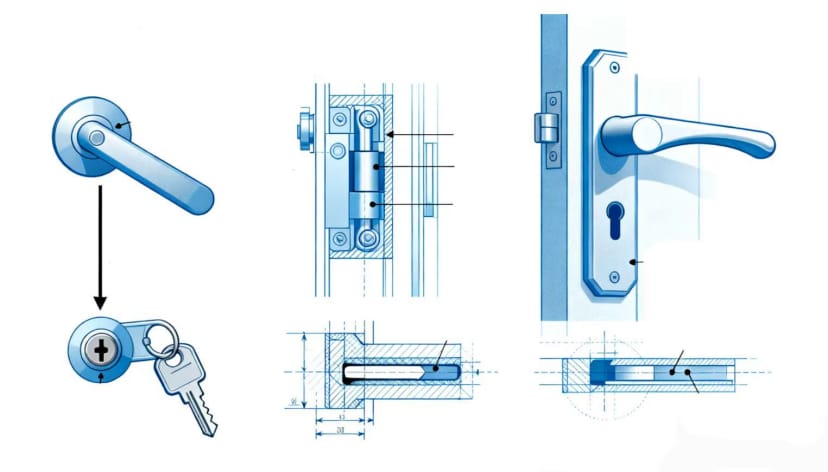

Cam locks are very popular because they are simple, reliable, and not expensive. They work when a key turns a small arm (a "cam") that swings behind the cabinet frame to lock the door.

They are flexible because they come in many different sizes, key types, and arm shapes to fit various doors. They are a great choice for general use, like on toolboxes and indoor access panels, where you just need to restrict casual access but do not need high security or a weather-tight seal.

When Should You Use Compression Latches?

You should use a compression latch whenever you need to keep out dust and water or prevent rattling from vibration.

Unlike a standard cam lock, a compression latch works in two steps:

It turns the arm to lock the door. It then pulls the door in tightly against a seal. This pulling action creates a firm, weather-proof seal and stops the door from shaking loose on things that vibrate a lot, such as RVs, specialty vehicles, or generator boxes.

You can look for more Compression Latches at https://fornd.com/category/stainless-steel-compression-latches-locks-for-doors.

What Makes Swing Handles Ideal for Server Racks and Electrical Cabinets?

Swing handles are optimum for larger and heavier doors like server racks, data centers, and large industrial control cabinets. Their primary advantage is mechanical advantage and ergonomics. The large, lever-type handle can open a multi-point latching system easily, where rods extend out of the central mechanism to latch the door top and bottom. This matters with regard to tall doors because it gives an even seal and does not warp the door.

From a manufacturing perspective, we make swing handles modular in design. Please kick it for more details https://fornd.com/product-category/handles/. They are made to be used with different locking inserts (from low-level tool-access to high-security keying) and are often provided in locking and non-locking versions for different levels of access in the same building. This combination of robust, multi-point protection with simple operation makes them the standard for application where both security and rapid access need to be achieved.

Lock Type | Primary Application | Key Advantages | Fornd's Recommendation |

Cam Lock | General-purpose enclosures, toolboxes, small access panels. | Simple, cost-effective, versatile, easy to install. | Indoor panels not requiring environmental sealing. |

Compression Latch | Electrical cabinets, HVAC units, RVs, marine applications. | Excellent sealing (IP/NEMA), vibration resistance, eliminates rattling. | Any enclosure with a gasket requiring protection from dust, water, or vibration. |

Swing Handle | Server racks, data centers, large industrial control cabinets. | Ergonomic, operates multi-point systems, suitable for heavy doors. | Tall or large doors where even sealing and robust security are paramount. |

Pawl Latch | Quick-access panels, small compartments. | Extremely simple, fast operation, economical. | Applications where speed of access is more important than security. |

What Key Factors Should Influence Your Lock Selection?

Apart from choosing the basic mechanism, several other aspects must be reviewed in order to ensure the lock functions as desired over its entire service life. These details are where the majority of projects fall through. A lock is not a solitary element but part of a system, and its material, dimensions, and conformance to standards must be carefully matched against the job. Omitting these details will compromise the integrity of the entire enclosure. At Fornd, we help you find the perfect lock by looking at three main things:

The Material: We check what the lock is made of to make sure it is strong enough for the job.

The Environment: We see how well it needs to protect against things like dust and water.

The Fit: We make sure the lock is the right size and shape to fit your cabinet perfectly.

How Does Material and Finish Affect Durability and Corrosion Resistance?

Material selection is important, especially for cabinets that will be exposed to moisture, chemicals, or saltwater. The durability and reliability of the lock are controlled by the base material and finish.

For common household applications, a zinc alloy with a chrome or black powder coating is usually the best compromise of toughness and cost. However, under more demanding conditions, we use higher grade materials. For out-of-door telecom cabinets or sewage treatment plants, 304 stainless steel provides superior corrosion resistance. In marine applications or where there is exposure to harsh chemicals, 316 stainless steel is the better option because it contains more molybdenum, giving better chlorides resistance.

Experience indicates that the finish is equally vital. An effectively applied powder coat can give thousands of hours of salt spray resistance, but if chipped, the underlying material is exposed. For the most severe applications, a stainless steel hardening is thus often the best bet.

What Do IP and NEMA Ratings Actually Protect Against?

IP and NEMA ratings are standards that tell you how well a cabinet protects what's inside from things like dust and water. It's very important to understand these ratings when choosing locks for important equipment.

IP Ratings

An IP rating has two numbers. The first number is for protection against solids (like dust), and the second number is for protection against liquids (like water). For example, an IP65-rated lock is completely dust-proof and can handle being sprayed with water.

NEMA Ratings

NEMA ratings are mostly used in North America. They are similar to IP ratings but can also include protection against rust and ice. A NEMA 4 rating is good for outdoor use.

How Do You Ensure Mechanical Compatibility and Easy Installation?

Mechanical fit is the final but key component of the puzzle. An incompatible lock will result in installation delays, security compromise, or a poor seal. The most important dimension to measure is the "grip range." It is the distance from the locking surface inside of the lock to where the cam or pawl bites into the frame. It should be equal to the thickness of your door plus the frame.

At Fornd, we provide detailed 2D and 3D CAD models for our entire range of products, allowing engineers to test fit digitally before ordering. Panel cut-out or hole preparation is another consideration of great significance.

You can find more hinges on the website: https://fornd.com/category/hinges.

How Can Fornd's Solutions Address Specific Industry Challenges?

Our work at Fornd is not just making parts, but engineering solutions for rare, occasionally challenging, industry issues. By working in close consultation with our customers from a wide variety of industries, we have gained a keen understanding of their specific operating conditions.

This gives us the capacity to recommend and modify hardware that not only guards an enclosure but also maximizes its performance and life. Whether it's for the latest 5G gear or off-road four-wheelers, our approach is to examine the issue and provide a proven, reliable piece of equipment.

You can learn more about locks and accessories suitable for different scenarios through the lock categories presented on the Fornd website, thereby ensuring your safety. Contact us now at info@fornd.com, or make a phone call at (+86)19533933853 to make your selection and request samples.

FAQs

What is the most secure type of industrial cabinet lock?

The safest kind is usually a multi-point lock. This type of lock secures the door in severalplaces (like the top, middle, and bottom). This makes it much harder to force open than a lockthat only secures one spot. For the best security, it should be paired with a high-security key.

What is the difference between a cam lock and a compression latch?

A cam lock is simple: you turn a key, and an arm moves to lock the door. it's one action. Acompression latch has two actions: first, the arm moves into place, and second, it pulls thedoor in tightly. This creates a tighter seal.

How do l find the right "grip range" for my cabinet lock?

The "grip range" is the thickness that the lock is designed to fit. To find the right one, youneed to measure the thickness of vour door or panel where the lock will be installed. Mostcompanies, including Fornd, offer locks with adjustable grips or different latch sizes to fitvarious thicknesses.