In industrial operations, with the roar of machines, precision is of vital importance. The simplest component is often overlooked - industrial hinges. The selection of hinges in any industrial application will significantly affect the performance, safety and service life of the entire system. A suitable hinge must be durable, reliable and suitable for the specific requirements of its operating environment.

In this hinge guide, we will analyze industrial hinges from core structures to wide applications, and explore their diverse types from multiple perspectives to help enterprises make informed decisions when choosing hinges that suit their specific industrial needs. However, when we turn the discussion to the topic of the quality and reliability of hinges, one brand inevitably stands out: Fornd - a brand synonymous with reliability, innovation and durability.

What Is the Structure of the Hinge?

A hinge, essentially, is a mechanical bearing used to connect components in a movable way. Usually, hinges only allow for a limited Angle of rotation between them.

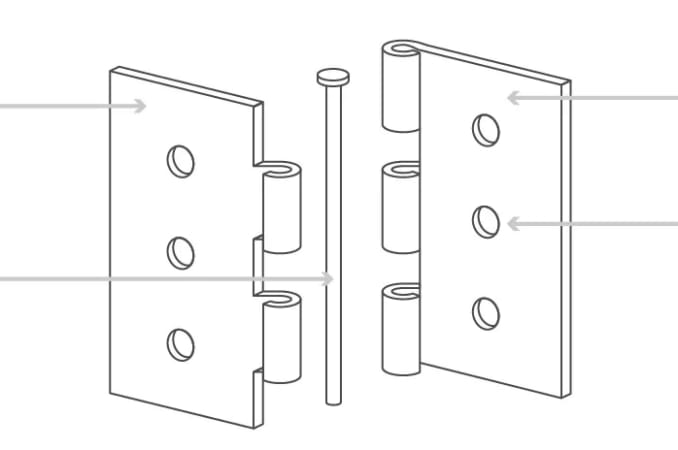

Before delving into the different types of hinges, we need to have a simple understanding of the basic structure of hinges. Hinges are mainly composed of the following components:

• Sheet: Two flat plates attached to the stationary part and the moving part. The size, thickness of the blades and the number of screw holes determine the load-bearing capacity and stability of the hinge.

• Ear roll: That is, the hollow cylinder formed when the pages interlock. Generally speaking, more ear curls have a higher load-bearing capacity and reduce the stress on the pins.

• Pin: A solid rod inserted into the ear to connect the plates and form a rotating shaft.

• Bearings: The common metal-to-metal interface between the pin and the ear will rub and wear excessively. Bearings are added to industrial hinges to reduce friction and make rotation smoother.

What Types of Industrial Hinges Are There?

Industrial applications require various types of hinges. It is far from sufficient to classify hinges based on a single characteristic. The following is a detailed breakdown from different perspectives to guide your choice. You can also browse Fornd's introduction to hinge types: https://fornd.com/blog/article/types-of-hinges-and-where-to-use-them

Classified by structure and design

1. Continuous hinge

Continuous hinges are also known as piano hinges because their leaf and ear structures are continuous and of the same length as the connected components (doors, panels).

This type of hinge is suitable for heavy-duty applications and effectively prevents sagging by evenly distributing the load and stress throughout the entire length. For instance, it is particularly suitable for heavy-duty doors, large inspection panels, aircraft inspection ports and long-side doors of automated equipment, etc.

2. Belt hinge

The notable feature of this hinge is that it has blades longer than the ear section, providing a huge surface area for fastening.

The design of the belt-type hinge distributes the load to a larger area, making it highly suitable for scenarios such as heavy-duty warehouse doors and farm barn doors that need to bear significant weight and stress.

Classify by function and operational characteristics

1. Detachable hinge:

The detachable hinge design enables the door or panel to move by "lifting", allowing for quick disassembly or installation without any tools.

For situations such as large electrical control cabinets and HVAC units that require frequent and rapid access to the interior of the equipment for maintenance, replacement or cleaning, detachable hinges are an ideal choice.

2. Friction hinges

The built-in resistance mechanism of the friction hinge ensures that a stable and consistent force can be provided at any position within its range of motion.

This type of hinge is typically used in situations that require precise positioning, such as industrial control panels and engine hoods of heavy equipment, etc.

3. Spring hinge

It is equipped with a built-in spring device that can provide an automatic shut-off function.

Spring hinges can ensure that the door closes automatically when unattended. Therefore, it is commonly found in industrial doors and passage doors where there are requirements for safety, hygiene or environmental control.

Classify by installation method

1. Welded hinge

The design of the welded hinge is that the blades are attached to the metal frame and the door by welding to form a permanent and durable connection.

It is the preferred choice for heavy machinery, steel security doors, electrically welded boxes, transportation equipment and outdoor heavy facilities, where hinges bear huge loads and harsh conditions.

2. Bolt-fixed hinges

It can be installed by bolts and nuts without welding, thus being easy to install, disassemble, adjust and replace on site.

The function mentioned above provides an ideal solution for situations where flexibility is required but welding cannot be carried out.

What Role Do Hinges Play in Industrial Applications?

The wide variety of industrial hinge types shows that the right hinge is crucial in countless industries.

Facts have proved that hinges are not merely mechanical connectors, but core functional components that ensure the efficient operation, convenient maintenance and safe operation of industrial equipment. Its value and role run through the entire life cycle of industrial equipment:

• Function realization: It provides flexible opening and closing of the equipment panel or door body, offering convenience for daily operation and maintenance.

• Safety protection: As a physical protective barrier, it is responsible for safeguarding precision components to prevent situations such as misoperation, dust intrusion, and unauthorized access, significantly enhancing safety.

• Durability and adaptability: For harsh working conditions such as vibration, corrosion, and temperature differences, industrial hinges provide reliable support, ensuring the service life of equipment over a long period.

• Performance optimization: Through designs such as heat insulation, sealing, and load-bearing capacity, energy consumption is reduced, stability is maintained, and operational smoothness and work efficiency are enhanced.

Similarly, Fornd also provided a detailed introduction to the application of industrial hinges, which you can refer to: https://fornd.com/blog/article/industrial-hinge-types-guide-where-to-use-them

About Fornd

Don't let hinges with insufficient specifications become the weakest link in your operation. The cost of a malfunction will far exceed the cost of investing in a high-quality component. Therefore, we suggest that you should invest in industrial hinges of high quality and reliability. This is equivalent to investing in the long-term stable operation of the entire system and the lowest total cost of ownership.

Fornd, a leading manufacturer with profound technological accumulation and strict quality control, offers a full range of industrial hinge solutions. The Fornd website is available at https://fornd.com/,contact the engineering support team to obtain expert consultation for your specific application.

FAQ

What is an industrial hinge?

Industrial hinges are connecting devices that allow connected components, such as doors or Windows, to swing.

How does a hinge work?

Hinges allow two components to open and close at an Angle to each other, which is restricted by the hinge structure and installation conditions.

What are stainless steel industrial hinges?

Stainless steel industrial hinges are designed for harsh environments where durability and corrosion resistance are crucial factors. These hinges are made of high-quality stainless steel and are highly suitable for outdoor or coastal applications.