The medical equipment industry operates in a very demanding environment when it comes to precision, reliability, and the upholding of safety standards. Though it may sound basic, the locks and hinges used in an industrial setting are key elements that directly play into how a piece of medical apparatus is as regards functionality, security, and even longevity. The industrial hardware greatly contrasts with the common household hardware since it largely conforms to very rigid safety regulations and can sustain frequent heavy-duty operations, as well as corrosion and even tamper-proof. This engineered specialty makes guaranteed consistent performance and safety to the high degree required in critical medical applications.

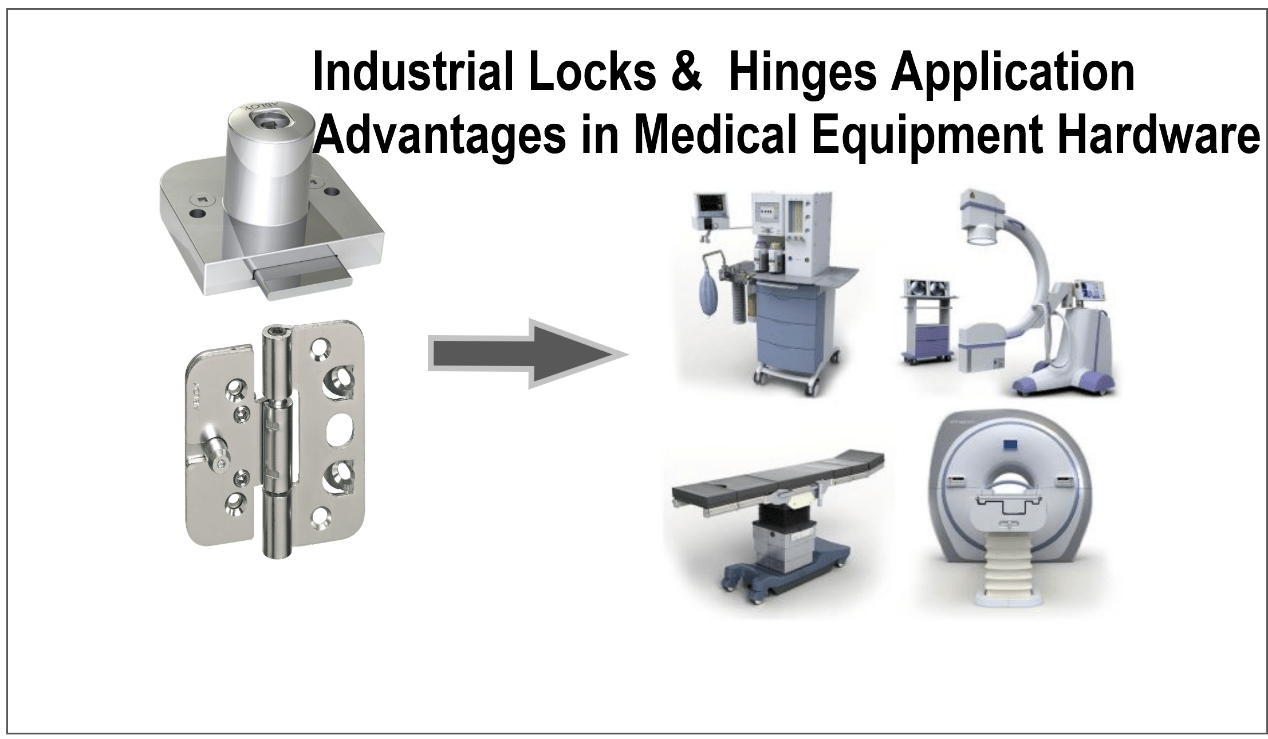

Applications for Medical Equipment Hardware

Industrial locks and hinges find widespread application across various medical equipment categories:

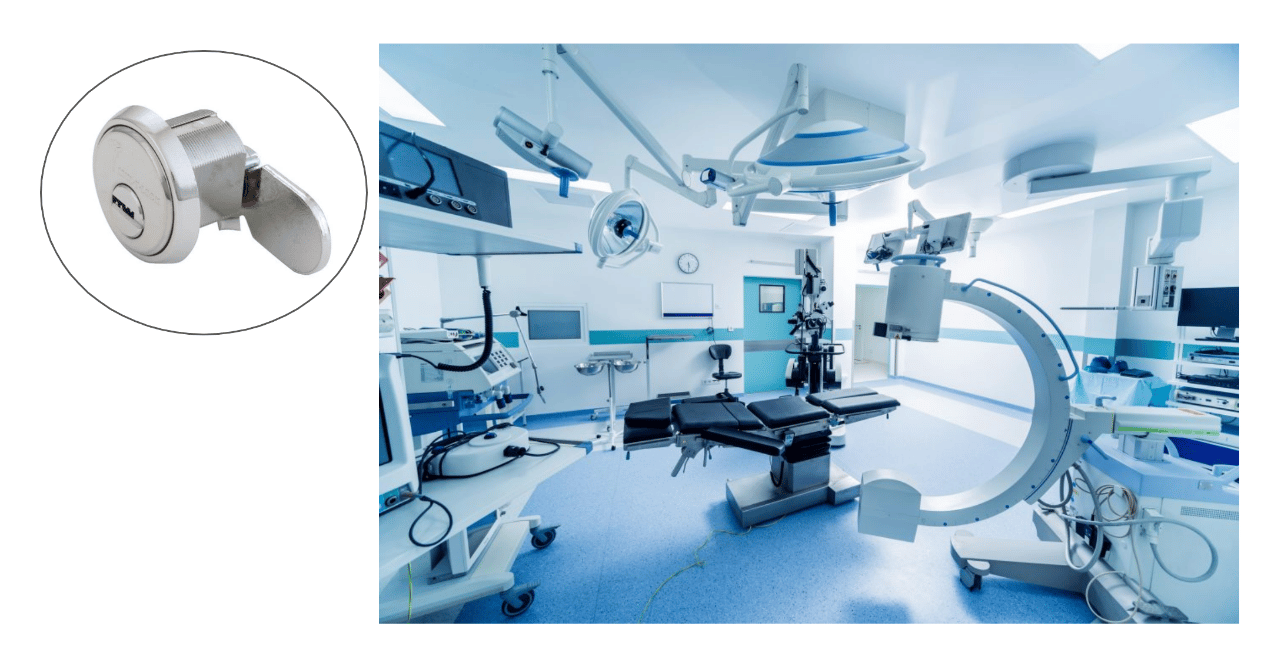

Operating Room Equipment

Industrial locks and hinges carry a weighty responsibility where operational theater equipment is concerned. It goes without saying that the correctness and faultlessness of their operation are to be of prime importance. Operating tables, for example, have heavy-duty industrial hinges that would allow the patient to adjust smoothly and firmly during positioning. In this case, it has to bear great weight and be readjusted often and yet remain absolutely firm and safe for the patient when any surgical procedure is in progress. Anesthesia carts and cabinets, where instruments are kept, require industrial locks to ensure steered conditions in the operating room and prevent anyone who is not authorized to have surgery-related drugs and tools. It is usually designed with features against tamper resistance as well as keyed-like systems for effective management. At the same time, corrosion-resisting this kind of hardware is also a necessity for use in a sterilized, rather damp operating room environment for longevity and consistency in its performance.

Patient Care Devices

Patient care devices like bedrails, stretchers, or patient lift systems play a critical role in patient safety and comfort since the adjustable features position the patient while at the same time being stable against any unwanted movements. In typical conditions, bedrails support the patient on the bed; for instance, hinges must operate smoothly and hold the weight of the patient without slipping. The composition should allow for the ready adjustment of the patient concerning healthcare providers while compliance needs to be observed. Patient movement is minimized since the patient will not injure themselves with such adjustments. It is an industrial lock for stretcher locks or patient lift systems, again ensuring that there will not be any false release, which shall then be a risk for the patient. These devices are also cleaned regularly, which means that the materials used must be stainless. The ability of the hardware, made of material likely to last long, to tread water for a long period of time is training not only as long as it is correctly used but also mitigating possible risks to the patient.

Pharmacy and Storage Solutions

Pharmacy and storage solutions within medical facilities must also ensure stringent security measures to safeguard medications, vaccines, and hazardous materials. A strong locking mechanism, however, should also be present. Industrial locks prove to be very effective, especially when tamper-evident features are also present and they provide a very clear indication of any unauthorized attempts of access that would deter potential theft or tampering. Even high-security cylinders to be used that resist any form of picking and drilling should also be installed as an added measure to protect such valuable and sensitive inventory. Additionally, electronic locks with audit trail capabilities have also found increased use in logging access events for accountability, making it easier to be compliant with regulations. This multi-layered security, therefore, is very important to ensure pharmaceutical supplies remain safe and maintain patient safety.

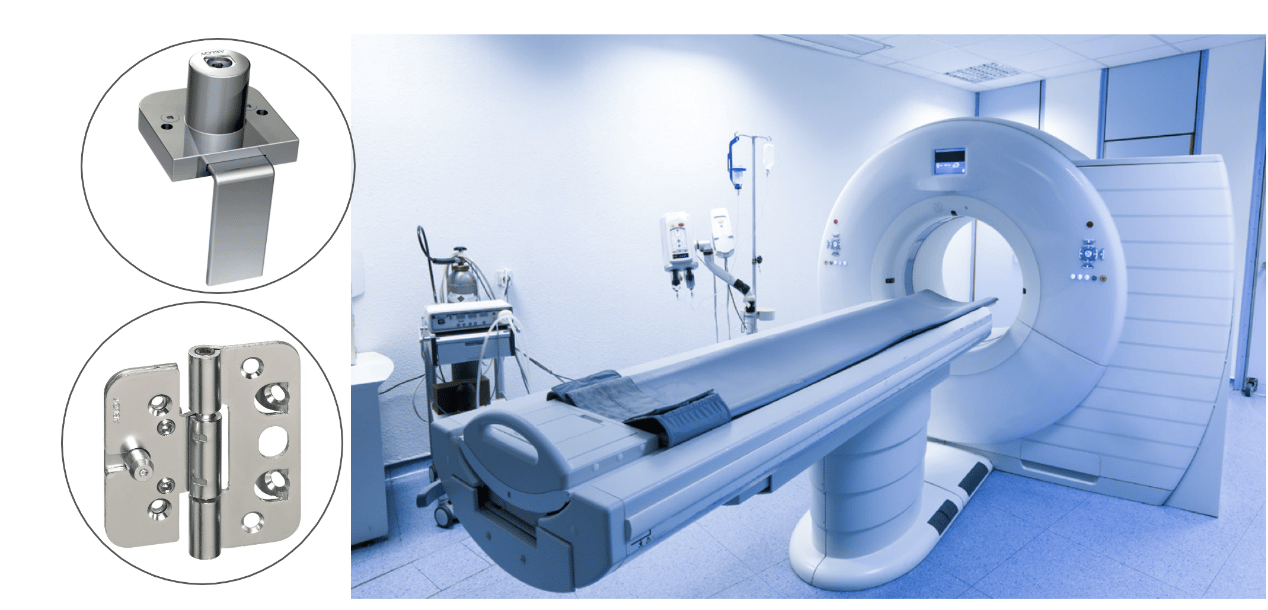

Diagnostic and Imaging Equipment

Specialized diagnostic and imaging equipment like MRI machines and X-ray units pose special challenges of access and security which call for custom constraint industrial hardware solutions. For example, an MRI machine may have oversized, heavy access panels that need robust hinges capable of handling heavy loads while ensuring smooth and precise opening and closure. Besides, it has to be maintained in position to avoid Electromagnetic Interference (EMI) to maintain accurate images. X-ray units may use special locks either to secure shielding against radiation or access panels, hence ensuring protection from accidental exposure and safety for the patient and operator. Industrial hardware is engineered for such applications with high safety standards and to cater to the sometimes intricate requirements of such devices. Diagnostic machinery must therefore be easy to operate and must be safe for the patient and the medical team using it; in the procedures done, industrial hinges and locks would offer the necessary functionality and ensure patient and staff safety.

Furniture and Fixtures

The facility's examination table and storage cabinets tend to be used with uncommon intensity, so their choice and placement demand heavy-duty industrial hinges and locks. In the case of examination tables, they require robust industrial hinges whose steadiness should be maintained, all things considered even very heavy patients who may have to sit on the table for some diagnosis, in good working condition, during adjustments. Waiting room seating, on the other hand, and storage cabinets usually have to endure the better part of human handling and benefit from secure locking systems. Within such applications, industrial-grade hardware improves the general efficacy, safety, and durability of furniture and fixtures - and ultimately a more secure and comfortable environment for both patients and healthcare providers.

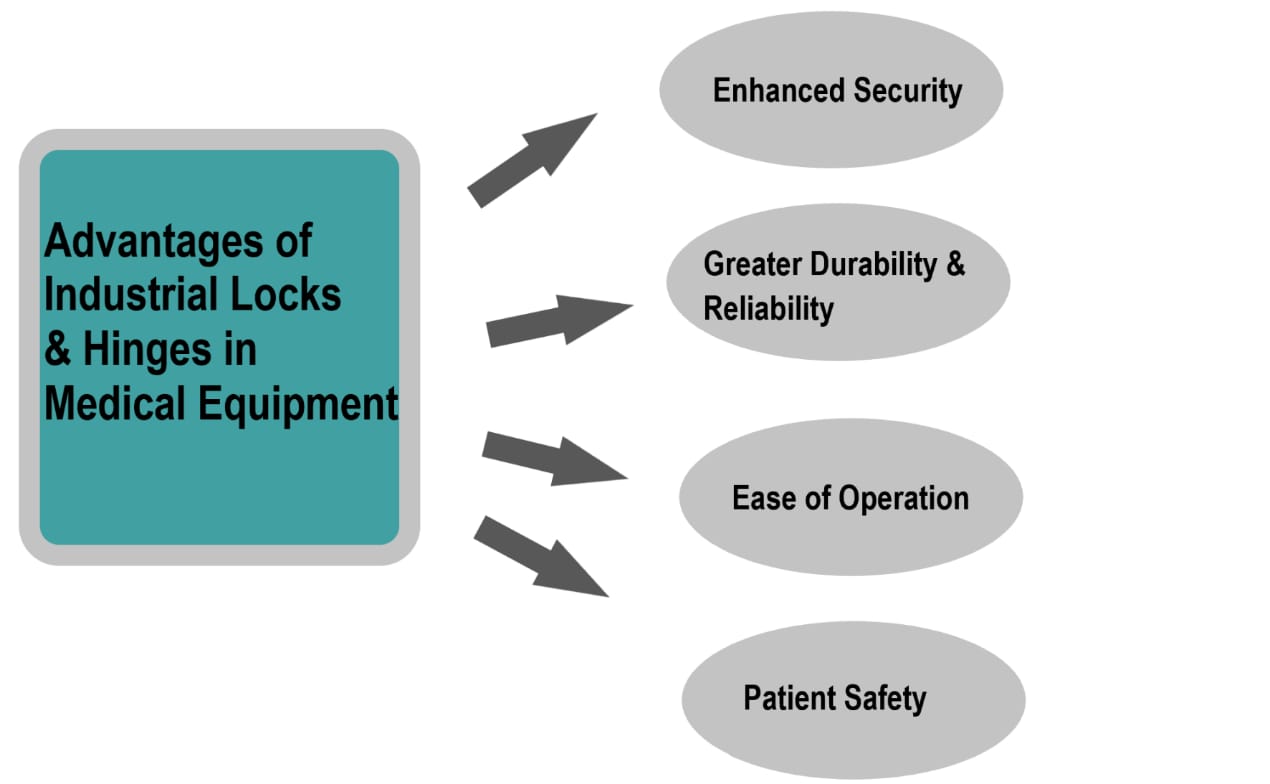

Advantages of Industrial Locks & Hinges in Medical Equipment

Medical facilities depend a great deal on how well every operation table and cupboard, the patient care gadgets, and even the cabinets function. Consequently, industrial-grade locks and hinges are indispensable, significantly enhancing the performance, safety, and longevity of these critical assets.

Enhanced Security

Industrial locks represent the ultimate solution to security and compliance in extreme medical and pharmaceutical applications. ABUS Medicloq provides biometric access systems with an error rate of less than 0.001%, compliant with the quite challenging standards in the world of medical devices, ISO 13485. High-security cylinders, for example, Medeco, are manufactured with tamper resistance of the highest standard and can withstand an attack for more than 15 minutes by drilling and picking, which makes them perfect for pharmaceutical storage of narcotics. In addition, the electronic locks with audit trail support in logging user IDs and timestamps help in complying with FDA 21 CFR Part 11 requirements on traceability when storing pharmaceuticals and in general improving the overall security at the same time.

Greater Durability and Reliability

Industrial-grade hinges and locks are engineered to meet the challenges presented by constant use, rigorous cleaning, and disinfection. Most of them are made from corrosion-resistant materials such as stainless steel. Since medical equipment is used in wet and sterile environments, much durability is expected from them. Heavy-duty construction which supports substantial loads and frequent movement without deformation or failure are used. Special coatings and materials are used to improve wear resistance, thus reducing maintenance needs and equipment downtime in the long run.

Ease of Operation

Industrial locks and hinges are most commonly used in situations where timing is critical, ensuring effortless access. Convenient for use with one hand, lever handles, and easily operable latch mechanisms allow even gloved responder hands to react quickly. Noiseless functioning creates no distractions within the observing and incredibly sensitive medical environment and maximizes attention to patient care. Adjustable hinges also increase the calibration range to any particular equipment needed and the running of the equipment needs to be smooth within the smallest available time.

Patient Safety

In medical equipment, a latch lock and hinge of industrial grade maintain patient safety. Proper secure closing that can be easily attained through positive latching prevents any accidental or unwanted opening thereby reducing risks of falls and injuries to patients. Such locks have child safety features that help restrict access to unauthorized persons for harmful substances or areas and such hardware. Besides, ergonomically designed, minimizes physical strain on the medical fraternity. All this, therefore, promotes an environment that is healthier and makes the maintenance of patients high-quality overall.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.