Why Do Large Control Cabinets Require Specialized Locking Systems?

Consider a big control cabinet as the vault shielding most private information of a business. You want a sophisticated, multi-tiered security system; a basic lock would not be sufficient. These cabinets, which house important operational controls, demand specific locking systems, much as a bank vault calls for more than a regular key. These systems guarantee that only authorized users may interact with the delicate and possibly dangerous inner workings, so safeguarding against both disturbance and risk by providing strong, often digital managed access.

A Comparison of 5 Mainstream Control Cabinet Lock Types

Now, let's take a look at 5 mainstream control cabinet lock types, focusing on their features, advantages, and disadvantages.

Key locks are the most basic and time-tested method of security. Used frequently in basic industrial settings, they rely on a physical key to activate a mechanical mechanism. For settings where complex security isn't an issue, their simplicity makes them a dependable and inexpensive option for locking cabinets.

Pros:

· Simple and reliable

· Cost-effective

· Easy to replace

Cons:

· Security can be compromised if keys are lost or duplicated

· Limited access control

· Not suitable for high-security applications

Padlocks are security solutions that are both portable and adaptable. They offer an easy, removable locking option for the outside of cabinets, with a shackle that passes through a handle or hasp. When an exterior lock that is easy to apply is required, these locks are often chosen for cabinet security because of their varied degrees of protection and convenience of use.

Pros:

· Portable and versatile.

· Relatively inexpensive.

· Various security levels available.

Cons:

· Can be easily cut or picked.

· Requires external hardware (hasps).

· Easily lost.

Combination Locks provide a keyless security substitute depending on a memorized code, mechanical or digital, for access. Perfect for cabinets where key management causes problems, they reduce the possibility of lost or repeated keys. Although mechanical models are simple, digital versions satisfy different security requirements by including audit trails and improved control.

Pros:

· Eliminates the need for keys.

· Offers moderate security.

· Digital versions can offer audit trails.

Cons:

· Combination codes can be forgotten or shared.

· Mechanical versions can wear out.

· Digital versions require power.

Electronic locks are now very critical in the modern industrial environment. They help to provide enhanced security and operational efficiency. What electronic locks have that mechanical ones do not, is the feature of electronic methods of validating a user, such as keypads, RFID cards, or even biometrics. They regulate access to sensitive areas and secure machinery for industrial use. They also manage the entry of people into certain restricted zones. This innovation does not only dessert help in a tighter security setting. So, this shall provide accurate records concerning the use of the entrance which could be very useful mainly for compliance and safety auditing purposes. Also, the locks can be integrated with a broader facility management system that will allow remote monitoring and control, therefore increasing efficiency in work and minimizing unauthorized persons' access.

Pros:

· Advanced access control features.

· Audit trails and logging capabilities.

· Remote access management.

Cons:

· Higher cost.

· Requires power supply.

· Potential for electronic malfunctions.

Rod control locking systems, which can be described as a way of securing large enclosures and cabinets, offer a kind of security that is, you know, strong and also multi-point. These systems utilize rods along with cams, which are, in a way, mechanisms that help in engaging many locking points all at once. This engagement, if you will, allows for the distribution of force in an even manner, which is good because it helps secure multiple doors or panels at the same time.

Pros:

· Provides robust security across multiple points.

· Distributes locking force evenly.

· Can be integrated with various lock types.

Cons:

· More complex installation.

· Higher cost.

· Can require more maintenance.

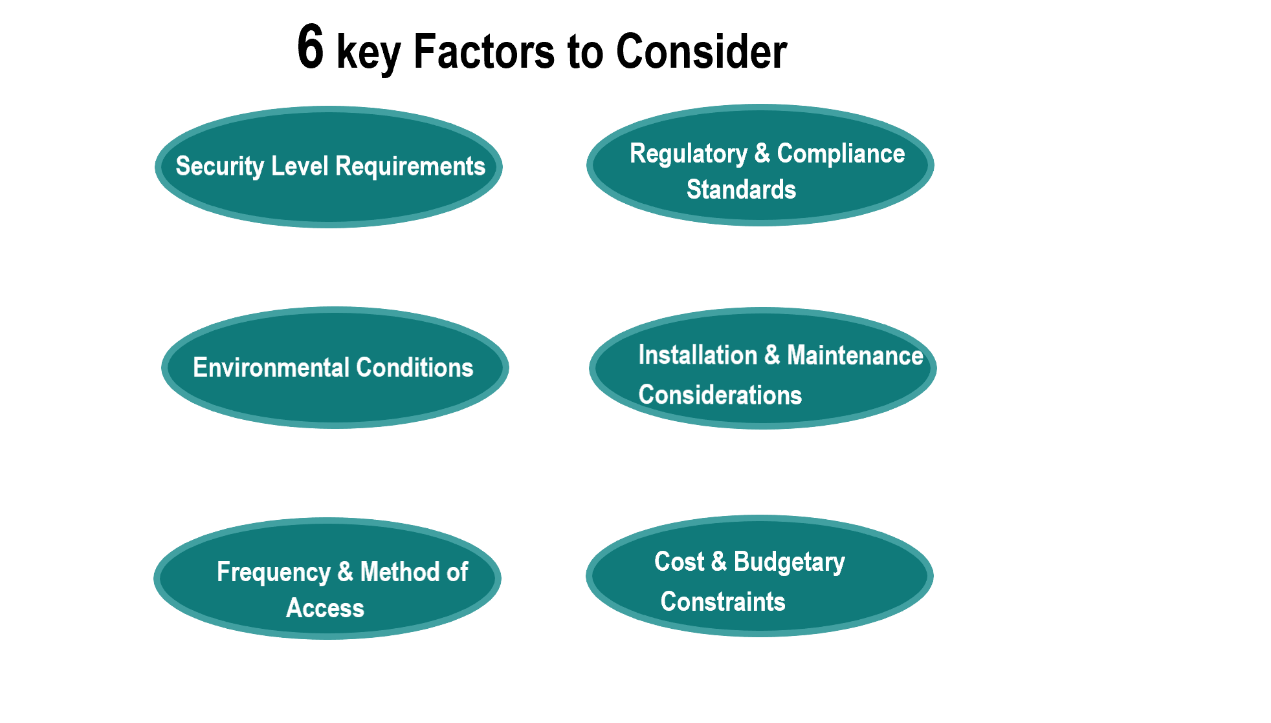

6 Key Factors for Selecting Locking Systems

Security Level Requirements: Find out what safeguards are required to prevent unwanted entry. A general-purpose industrial cabinet may merely need a strong key lock, while a data center cabinet housing vital network servers requires a high-security electronic lock with audit trails.

Environmental Conditions: Assess the operational setting. A high-IP-rated lock, such as an industrial-grade padlock with a sealed shackle, is required to secure a control cabinet in a dusty production facility. Locks in server rooms with climate control, on the other hand, don't have to worry about such things.

Frequency and Method of Access: Think about the frequency and users of the cabinet's access. It may be more convenient to use a combination lock or RFID access to eliminate key management for a cabinet that is accessed numerous times daily by different technicians. The use of a regular key lock on an infrequently used cabinet may be adequate.

Regulatory and Compliance Standards: Make sure that rules set by the industry are followed. Conforming to safety standards such as UL or IEC may necessitate locks with particular certifications or lockout/tagout capabilities in a cabinet housing high-voltage components.

Installation and Maintenance Considerations: Consider the installation and maintenance ease. Although sturdy, a rod control locking system necessitates expert installation and regular servicing. Installing and maintaining a basic key lock is a breeze.

Cost and Budgetary Constraints: Strike a balance between finances and security requirements. A biometric lock is more costly, but it provides top-tier security. An inexpensive key lock or padlock may be adequate security for a simple filing cabinet.

Best Practices for Installation and Maintenance

Perfect installation of control cabinet locking systems starts with a thorough design. Correct alignment and operation depend on exact measurements and following manufacturer recommendations. Fasteners and suitable tools help to guarantee a secure fit and stop damage. Complete testing following installation guarantees the dependability of the locking mechanism, therefore resolving any possible problems before they become more serious. For electronic locks, regular software upgrades help to preserve security and performance in addition to appropriate wiring and network design.

Both dependability and lifespan depend on regular maintenance. The components should be inspected often for indications of wear, corrosion, or damage, and any defective parts should be replaced without delay. Follow the manufacturer's instructions for lubricating mechanical parts to keep them from seizing and run smoothly. Every so often, you should check the status of your electronic locks' access control systems and backup batteries. Making sure to keep track of all maintenance activities is crucial for troubleshooting and future planning. This will help minimize downtime and make sure the locking system lasts as long as possible.

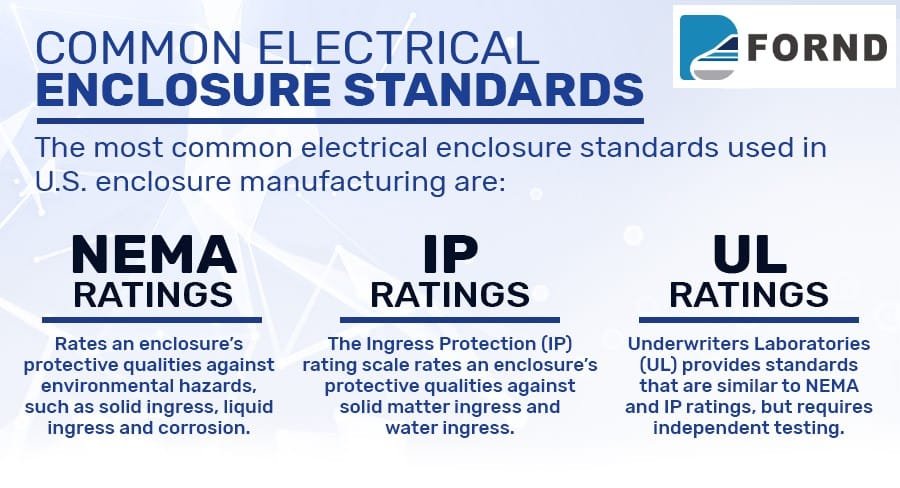

Industry Compliance Requirements (IEC/UL/NEMA Standards)

For control cabinet locking systems to be reliable and safe, they must adhere to industry standards such as IEC, UL, and NEMA.

When we talk about electrical and electronic technology, there is this organization, you see, called the International Electrotechnical Commission, or IEC for short, which is really quite important. They have, in fact, set up standards that are intended to cover various aspects, particularly the performance and safety of those mechanisms that lock things up in electrical enclosures, which are, as one might say, quite essential. The certification and testing of these locking systems, which are meant to endure certain environmental conditions and ensure electrical safety, is often shown by their compliance with the standards that IEC has laid down.

Now, shifting focus a little, we have another entity known as UL, which stands for Underwriters Laboratories. This organization, primarily relevant in North America, has standards that focus on product safety, which is a big deal, really. When we refer to locking systems, it is important to note that their adherence to UL standards is crucial, especially in the North American market. The main point to consider here is that safety, as emphasized by UL, remains of utmost importance, and thus, it becomes vital to ensure that these locking systems meet such safety standards that UL prescribes.

(NEMA) The National Electrical Manufacturers Association has developed standards that list the various kinds of enclosures and the degrees of protection they provide. A device's enclosure and, by implication, its locking mechanism, are rated according to the National Electrical Manufacturers Association (NEMA) standards, which can range from 4 to 12. Maintaining the protective integrity of the cabinet and securing internal components and personnel is ensured by ensuring that locking systems match with applicable NEMA ratings.

Future Trends in Smart Locking Technology

Regarding control cabinet locking mechanisms, one can observe, quite inevitably, that those older systems, which are not very reliable and perhaps a bit outdated, are being replaced by newer ones that are, in a manner of speaking, smarter. These modern systems utilize biometric identification methods, which may involve recognizing faces or fingerprints, thereby providing a form of security that is enhanced and more individualized. This is in stark contrast to traditional systems that rely on keys or codes, which have their own weaknesses, as one might say. Furthermore, one can manage and monitor these locking systems from virtually anywhere, thanks to what is known as the Internet of Things, a rather complex term that implies connectivity. Administrators can grant or revoke access privileges from afar, which is indeed a remarkable feat. They can also receive alerts in real-time, which, while it may sound impressive, raises questions about how timely these alerts truly are. Thus, the ability to control access remotely adds a layer of convenience, though one might wonder if it compromises some other aspects of security, or perhaps not. In summary, the shift from older technology to these newer, smarter locking systems is a trend that seems to be taking place, and one might ponder the implications of such a shift for the future of security in various contexts.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.