A Beginner’s Guide to Understanding Mortise Locks and Their Advantages

When you shut a heavy door in a busy office or hotel, you expect it to feel solid. That solid click often comes from a mortise lock. Unlike the lighter locks found on thin doors or cabinets, mortise locks are built right into the body of the door. They take more effort to install, but once in place, they provide strength, security, and years of service.

In this guide, we’ll break down what a mortise lock really is, the types you’ll run into, the advantages they bring, and how to think about materials, finishes, and where they’re best used. We’ll also touch on installation basics and answer common questions. Along the way, we’ll show examples from Fornd, whose lineup of locks and hinges gives practical options for industrial and commercial doors.

What Is a Mortise Lock and How Does It Work?

What “Mortise” Means?

When people say mortise, they just mean a pocket cut into the edge of the door. The lock body slides into that pocket so it sits snug inside the wood. It’s not hanging on the surface like a simple latch—it becomes part of the door itself. That’s why mortise locks feel solid: the door is holding the lock, and the lock is holding the door.

Internal Components

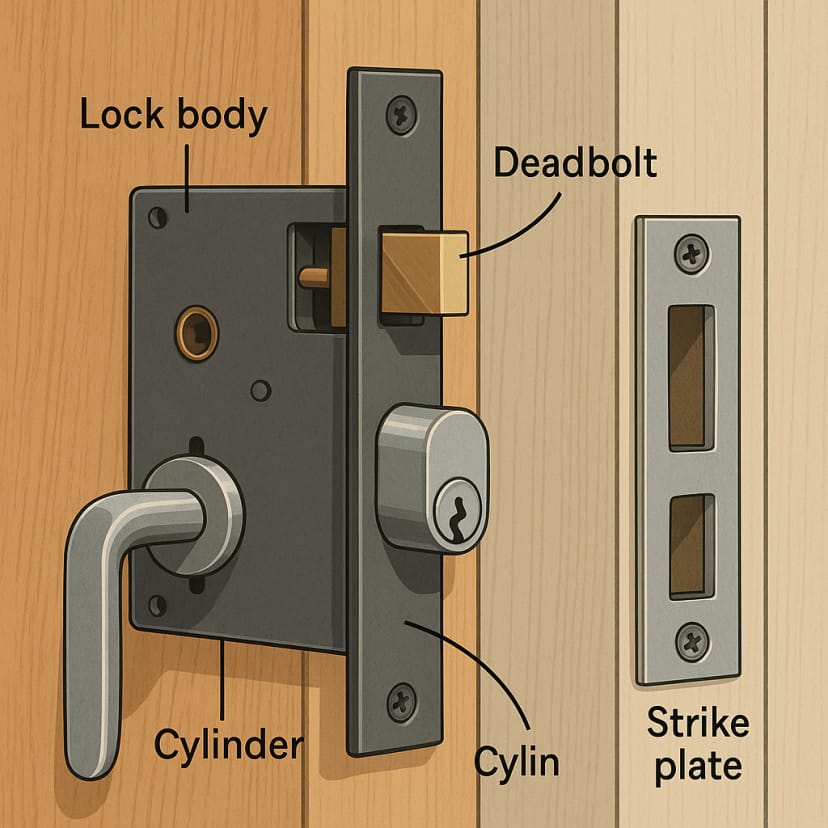

A mortise lock isn’t complicated once you break it down. Inside, there’s the lock body—basically a small metal box tucked into the edge of the door, holding everything in place. Then comes the latch. That’s the springy bit you hear click every time you close the door. It keeps the door shut without you needing to lock it.

For real security, there’s the deadbolt. When you turn the key or thumbturn, that heavy piece of metal slides out. That’s the part that makes the door hard to force open. The cylinder is just the keyhole and the mechanism behind it. Twist the key, and it tells the latch or the deadbolt when to move. Finally, there’s the strike plate on the frame. The latch and bolt slide into it, and it takes the pressure so the wood around the frame doesn’t wear out too fast.

Think of it like a team: the body is the frame, the latch is the everyday helper, the deadbolt is the muscle, the cylinder is the brain, and the strike plate is the shield that keeps everything firm.

Latch vs. Deadbolt vs. Cylinder

Think of it this way: the latch is the everyday worker, the deadbolt is the guard on night duty, and the cylinder is the boss telling them when to move.

What Types of Mortise Locks Are Out There?

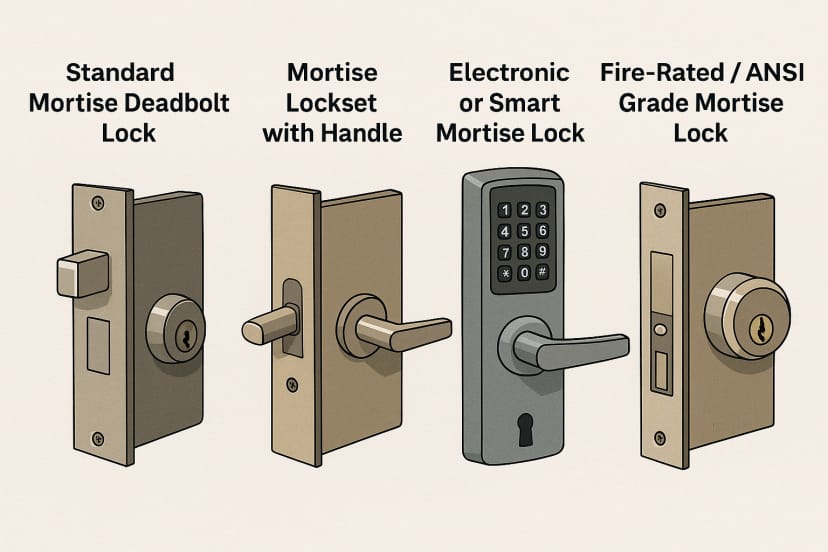

Standard Mortise Deadbolt Locks

These are the straightforward ones. No handles, no levers—just a lock body with a deadbolt. You use a key or thumbturn to slide the bolt in and out. They’re often paired with a separate handle or knob. People like them when the only goal is to lock the door tight, nothing extra.

Mortise Locksets with Handles

This is the more common setup in hotels and apartments. Instead of buying a separate handle and lock, everything comes in one unit: the latch, the deadbolt, and the lever or knob. You push the handle for daily use, and when you need security, the deadbolt locks it down. It’s neat, easy for users, and saves space on the door.

High-Security Mortise Systems

Here the focus is on blocking tampering. These locks may have restricted keyways so blanks can’t be copied easily, or hardened inserts to resist drilling. Some also add anti-snap or anti-pick features. They show up in places like offices, banks, or buildings that need more than just a basic latch.

Electronic or Smart Mortise Locks

These combine the solid feel of a mortise lock with modern access. You might swipe a card, punch in a code, or even use a phone app. The mortise body still gives strength, but the control moves beyond a simple key. Hotels, offices, and newer apartments are where you’ll see these most often.

Fire-Rated / ANSI Grade Mortise Locks

In commercial spaces, it’s not just about keeping people out—it’s about safety rules. Fire-rated mortise locks are tested to hold up under extreme heat. ANSI grade ratings tell you how tough the lock is, from light use up to heavy-duty. You’ll find these on school doors, hospital wards, or any place that gets constant traffic and must meet building codes.

What Advantages Do Mortise Locks Offer?

Security and Resistance

A mortise lock doesn’t just sit on top of the door—it’s built into it. That deeper body gives the bolt more room and strength, so when someone tries to force the door, the lock can take the hit. The deadbolt is thicker and set deeper than on most simple locks, which makes kicking or prying a lot harder.

Durability and Long Lifespan

These locks are made to be used thousands of times a year without breaking down. The moving parts are heavy duty, not thin stamped metal. In hotels or schools where doors never get a rest, mortise locks keep working long after lighter locks would be loose or failing.

Cleaner Look

Since the lock body hides inside the door, the only thing you see is the handle and trim. No bulky box on the surface, no odd hardware sticking out. It gives a neat, finished look that blends with the door design.

Keying Flexibility

Mortise locks can be set up in different ways—keyed alike, master-keyed, or with restricted keyways that stop people from making quick copies. That means you can decide how much control you want, from a single apartment door to an office with many levels of access.

Smooth Use

People often notice the “feel” of a mortise lock. The handle turns with weight, the latch clicks in smoothly, and the deadbolt slides with a solid motion. It doesn’t rattle or feel cheap. That sense of stability is one reason they’re chosen for places that want both strength and a professional touch.

What Materials and Finishes Make Sense?

Here are some common materails.

Material / Finish | Why It’s Good | What to Watch Out For |

Brass | Feels smooth under the key. Classic look. | Tarnishes or darkens in damp or humid air. It needs polishing if you care about appearance. |

Stainless Steel | Doesn’t rust, holds up outdoors or near moisture. Long-lasting. | It can be heavy. More expensive. Sometimes harder to match with decorative trim. |

Zinc Alloy | Cheap to make. Good shapes for smaller components. | Not as strong long term. Once finish wears, base metal may corrode or weaken. |

Coated / Chrome-Plated Steel | Gives the strength of steel with a pretty finish. Chrome or powder coat can resist wear. | If the coating chips or gets scratched, rust will start. Maintenance of finish important. |

How Fornd’s Hardware Helps Show What Matters

Even if they’re hinges and not locks, these products face daily swings, weight, and weather. That makes them a handy “real life test” for how different finishes behave—knowledge you can use when choosing mortise locks in the same materials.

Image | Model | Material / Finish | Link |

| H2-2352-A1A – Heavy-Duty Concealed Hinge (Stainless Steel, Polished / Bright) | Stainless steel, bright & polished finish. High strength, concealed type. fornd.com | https://fornd.com/product/concealed-removable-hinges-h2-2352-a1a |

| H2-2382-A1 – Recessed Removable Hinge | Stainless steel, polished bright. fornd.com | https://fornd.com/product/concealed-removable-hinges-h2-2382-a1 |

| H2-2385-234-A1 – Concealed Removable Hinge, Stainless Steel, Passivated | Stainless steel; passivated finish for durability. fornd.com | https://fornd.com/product/concealed-removable-hinges-h2-2385-234-a1 |

| H2-2351-A1 – 135° Concealed Removable Hinge | Stainless steel, passivated. Original color finish. fornd.com | https://fornd.com/product/concealed-removable-hinges-h2-2351-a1 |

| H2-2357-A4 – 135° Hidden Removable Hinge, Heavy Duty | Zinc alloy, powder coat black. Heavy-duty use. fornd.com | https://fornd.com/product/concealed-removable-hinges-h2-2357-a4 |

Where Do Mortise Locks Work Best?

Commercial Buildings

Mortise locks are almost the default in offices, schools, and hospitals. These doors get opened and closed hundreds of times a day, and a lighter lock just won’t last. A mortise setup handles that constant cycle and keeps things secure without the latch wearing out too soon.

Hotels and Apartments

In places where people rent or stay short-term, locks need to feel solid but also easy to use. Guests expect the door to close smoothly and lock with one turn. Mortise locksets with handles combine latch and deadbolt in one unit, which makes them perfect here—they balance comfort with strength.

Industrial and Utility Doors

Think about factories, storage facilities, or utility panels. These doors are thicker, heavier, and sometimes exposed to harsh conditions. Mortise locks fit deeper into the edge, so they handle the stress without bending or failing.

Not for Thin Doors

One clear limitation: hollow or lightweight doors. If the door doesn’t have enough depth, you can’t cut the pocket needed for a mortise lock. In that case, a surface-mounted or cylindrical lock is usually the better choice.

How Do You Install a Mortise Lock?

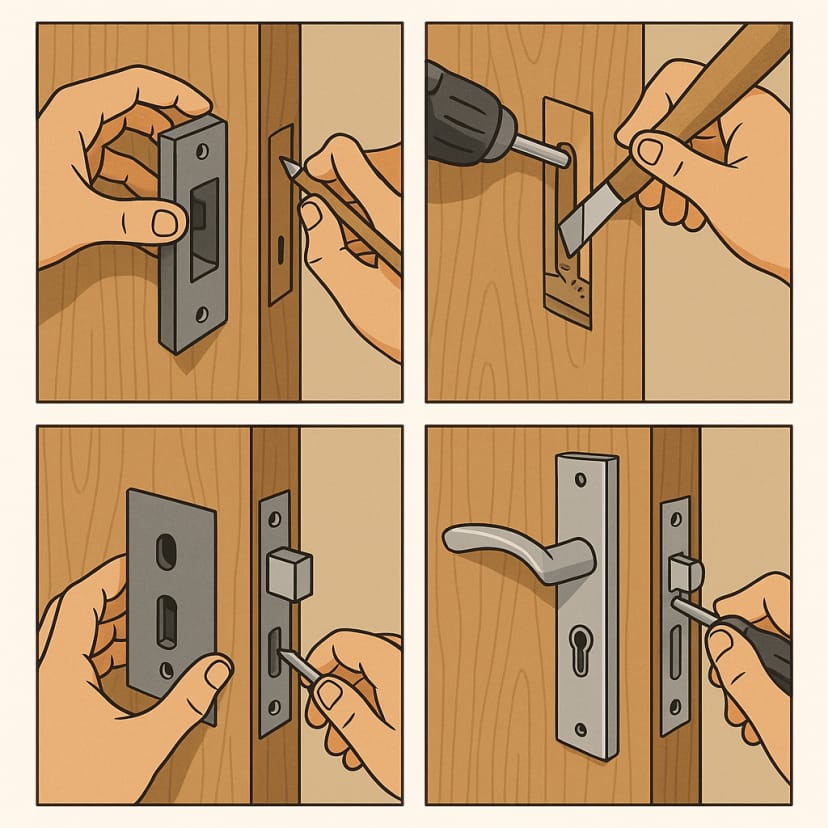

Step 1: Gather Your Tools

Before you even touch the door, lay out what you’ll need: a drill, chisels, screwdrivers, a square, and a pencil. If you have a mortise jig, it will be even better. It keeps things neat. If not, a chisel and patience will do the job.

Step 2: Mark the Pocket

Hold the lock body against the edge of the door and trace it. Mark the depth too. Think of it as drawing the “parking spot” for the lock—you don’t want it too loose or too tight.

Step 3: Cut the Mortise

Drill out most of the wood first, then clean it up with a chisel. Take thin slices instead of big chunks. Slow and steady here gives you a snug, solid fit.

Step 4: Test the Fit

Slide the lock body in and see how it sits. It should be flush with the door edge, not sticking out, not rattling around. If it’s binding, shave a little more. If it’s wobbly, you may need a shim later.

Step 5: Drill for the Cylinder and Handles

With the body in place, mark where the keyhole and handle go. Drill straight through both sides of the door so they line up. Pop the cylinder and handles in just to check that everything fits.

Step 6: Fit the Strike Plate

Close the door gently and extend the latch and bolt. Wherever they hit the frame, that’s where your strike plate belongs. Cut a shallow recess, screw the plate in, and make sure the latch and bolt slide in clean.

Step 7: Final Assembly and Test

Now put it all together for real. Tighten the screws, attach the trim, and close the door a few times. If it drags or doesn’t catch, back off the screws a little, adjust, then snug them down again. The goal is a smooth swing, not a fight.

FAQs

How is a Mortise Lock Different from a Barrel Lock?

A mortise lock is the whole setup that goes inside the edge of your door—latch, deadbolt, cylinder, all in one box. A barrel lock is only the cylinder part where the key turns.

Can I Put a Mortise Lock on Any Door?

Not really. You need a solid, thick door to carve the pocket for it. Thin or hollow doors just don’t have enough material to hold it.

How Long Can One Last?

A good mortise lock in brass or stainless can run for decades with little trouble. A cheap alloy stuck outside? You might see rust or failure in just a few years.

Are Mortise Locks Just for Offices or Hotels?

No. You’ll see them in commercial buildings, sure, but also in homes—especially in higher-end apartments or older houses where people want both strength and a nice finish.

Looking for reliable hardware? Browse Fornd’s full lineup here: https://fornd.com/ and order your motise lock now.