In an arena traditionally belonging to metal as the most common material of fastening solutions, latches of non-metallic origin come to the front as versatile problem solvers, and quietly bring a revolution in the means of securing anything, from underwater camera cases to aerospace components. These engineered polymer and elastomer alternatives to traditional latches of metal come to fill the niche of advanced material-oriented sciences with innovative design that offers specialized performance advantages. Admittedly, these are not substitutes but lightweight, corrosion-resistant fasteners offering unique capabilities that range from providing electric insulation in high-voltage applications to chemical resistance in aggressive settings and therefore turn into such integral components the moment applications do not welcome traditional metal solutions.

Non-Metallic Latches Based on Material: Plastic & Rubber Latches

Plastic Latches

Plastic latches are made from a variety of polymers selected for specific performance characteristics. ABS offers a good balance of properties with excellent impact resistance and strength; it is suitable for latches in consumer electronic devices, such as laptops and cameras. Some of the toughest and most transparent materials, polycarbonate latches are used typically in medical equipment enclosures where use-through closure is required. Nylon latches typically offer good tensile strength and wear resistance and are well-suited for applications such as automotive latches in glove compartment doors and center console lids. Good chemical resistance and fatigue resistance are found with polypropylene latches, so they are excellent for applications such as laboratory equipment and food containers. Acetal (POM) is a latch material with high stiffness and excellent dimensional stability, and it is commonly found in precision applications, such as instrument cases. PEEK (polyetheretherketone) latches can provide latch function at extremely high temperatures, up to 250°C, typical of high-temperature industrial applications.

Rubber Latches

Different elastomer formulations provide unique functional benefits. EPDM rubber latches provide excellent weather resistance and UV stability. Ideal applications may include outdoor equipment cases, and marine applications, etc. Neoprene rubber latches provide good oil resistance and fair chemical resistance. Most common applications are automotive underhood components and industrial control panels. Silicone rubber latches keep flexibility over a wide range of temperatures (-60°C to 230°C) and are hypoallergenic. Most common applications are enclosures for the medical field and for food processing equipment. Natural rubber latches provide good elasticity and tear strength. Most common applications are where seals are used and heavy repeated stretching is required, such as seals for waterproof containers. Fluoroelastomer (FKM/Viton) latches provide extremely good chemical resistance to a fuel as well as to a solvent. Most common applications are latches for the aerospace industry as well as for chemical processing equipment.

Non-Metallic Latches Based on Functionality and Design

Push Button Latches

Push button latches use a spring-loaded mechanism that is actuated when pushed. Commonly these are used for single-hand operation without the requirement of any tool or handle. Small in size, these latches are mostly used in electronic enclosures and cabinet doors or places where the storage compartments in vehicles are relatively small. The current designs are likely to use soft-touch materials to increase ergonomics, whereby possible features might be waterproofing and children protection-with this, unlocking will need specific pressure patterns.

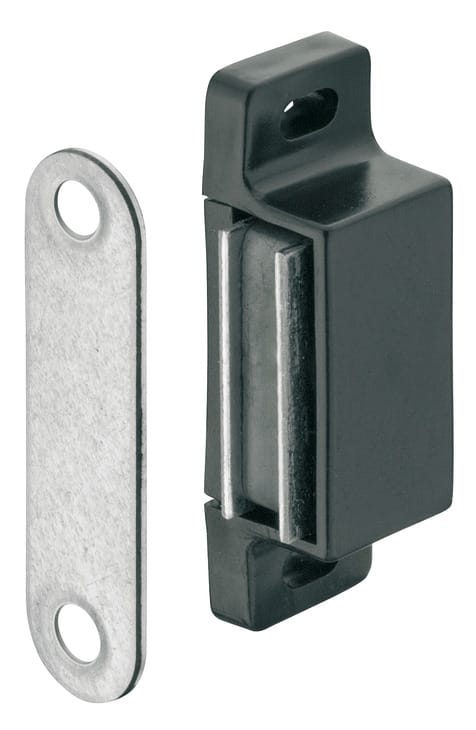

Magnetic Catches

Magnetic catches utilize powerful neodymium or ceramic magnets embedded in a housing that attracts a corresponding metal strike plate to hold doors closed. The magnetic force is available in different strengths for light cabinet door retention to strong panel closure. Advanced versions come with adjustable magnetic tension, rubber dampeners to prevent slamming, and hide totally within the cabinetry for a clean, handle-free look in modern furniture.

Draw Latches (Tension Latches)

Draw latches generate mechanical tension between two surfaces by pulling them together when engaged. Thermoplastic over-center draw latches simulate metal latches and add corrosion resistance and vibration dampening, while reducing the weight and cost, especially for use in transport cases. Those made of rubber T-handles take advantage of the flexibility of the elastomer; when locked, it is actually a continuous piece that will tend to stretch, creating consistent tension over the wide range of outdoor equipment type of conditions. A living hinge is a one-piece plastic hinge that allows for the plastic material at the crease of the hinge to be more flexible than would be a separate piece attached to the hinge, thus reducing cost and potential failure point for a moving consumer good.

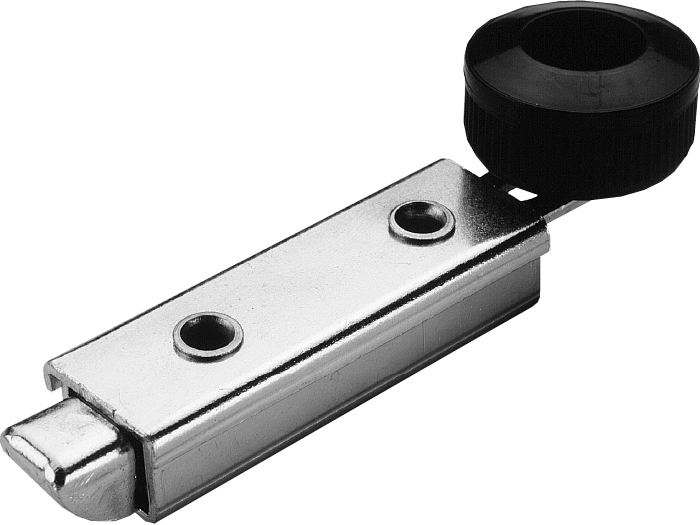

Slam Latches

Slam latches feature an angled bolt or catch that automatically engages when a door is pushed closed, compressing an internal spring that later assists in door opening.Slam latches of this kind are mostly used in industrial cabinets, doors of vehicles, and gates—places where quick and reliable closing is of utmost importance. With the advanced versions, you can adjust the strike plates to align the bolt better. Rubber bumpers of these versions reduce the noise and vibration during operation.

Cam Latches

A rotating eccentric disc (or cam) that turns behind a frame or strike plate holds a door or panel securely. The amount of compression is a function of the shape of the cam, while the ergonomics for the user depend on the arc through which the cam rotates. These may be designed to have a 1/4 turn, 1/2 turn or multiple turns to suit the level of security as needed and find wide application in the fixing of electrical boxes, access panels for HVAC, and transport crates since their tool-operated versions add one more level of security.

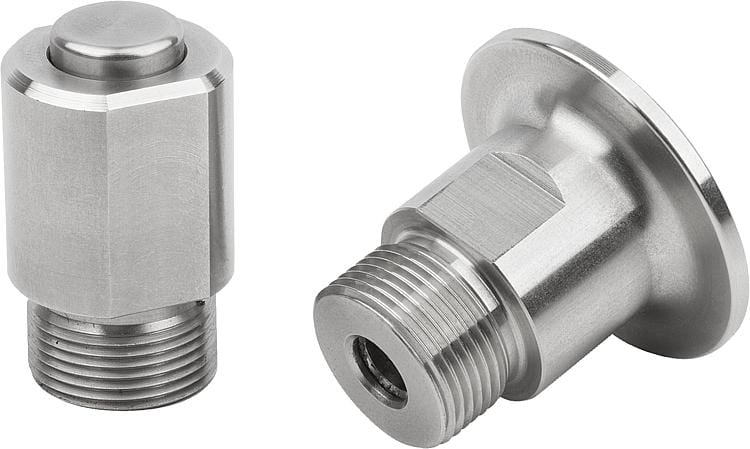

Compression Latches

Compression latches combine both the features of rotary or over-center action and a ramp mechanism which in turn pulls surfaces closely together; hence, creating a pressure against a gasket or seal. This compression makes itself into a weather-tight, dust-proof, or even waterproof seal which is critical for the outdoor equipment, marine applications, and sensitive electronics enclosures. Some advanced designs are coming with adjustable compression settings together with ergonomic handles having leverage advantages and multi-stage locking positions so that locking can be made even when the gasket wears off after a certain time.

Handle Latches (Plastic Handle HVAC Latches)

Handles and latches combine gripping with latching in a manner such that ergonomics are comfortable while operating, and at the same time doors or panels are securely secured. In HVAC applications, these have to withstand the cyclic loads, that is, temperature variations, vibrations, and frequent service access. Handles range in design from simple L-shaped to ergonomically contoured which can provide a leveraged advantage for compression of a thick gasket, with material selection for UV stability, impact resistance at low temperatures, and non-conductivity for electrical safety.

Advantages of Non-Metallic Latches

Corrosion Resistance

Non-metallic latches keep both strength and look when exposed to the same conditions that easily rust away at metal latches. These based on polymers are perfect for use in marine environments, outdoor equipment, and places where food is processed and stored, and chemical facilities because in such places, metal parts would rot very fast. This will extend the service life and reduce the maintenance needs, although to a smaller degree.

Non-Conductive Properties

With excellent electrical insulation characteristics, non-metallic latches prevent current flow and reduce shock hazards in electrical enclosures, junction boxes, and battery compartments. Their dielectric strength (typically 15-20 kV/mm for materials like polycarbonate) provides essential safety margins in applications ranging from consumer electronics to industrial control panels, eliminating the risk of short circuits or unintended grounding.

Lightweight Design

Non-metallic latches weigh 80-85% less than their metal counterparts because the polymers used have a density of 1.0-1.5 g/cm³ as compared to steel, which has 7.8-8.9 g/cm³. This weight saving benefits applications in the transport sector, portable equipment, and aerospace components—where fuel efficiency, user comfort, and operational costs are directly related to weight.

Chemical Resistance

Polymers are formulated to offer selective resistance to different chemicals that would otherwise degrade metals. Fluoropolymers take very strong acids and bases, acetal is going to take solvents, and hydrocarbons, and polypropylene is going to take common household chemicals. This is why non-metallic latches are ideal for applications in laboratory equipment and chemicals where the metallic ones cannot be used with cleaning agents that are so prevalent in medical applications.

Flexibility and Sealing

Elastomeric latches from materials such as EPDM, silicone, or neoprene. They compress against mating surfaces. In return, they create seals, which are impervious to water and to dust without using gaskets. It simplifies design as an added integral elevation while providing damping in terms of vibration in transportation applications and preserving steady or constant tension even if there is a change in wear or temperature.

UV Resistance

Specially formulated non-metallic latches with UV stabilizers or carbon black maintain mechanical properties and appearance despite years of sun exposure. High-quality outdoor-rated polymers retain 90%+ of their strength after 5+ years of continuous UV exposure, making them suitable for solar mounting systems, outdoor furniture, and agricultural implements.

Cost-Effectiveness

Non-metallic latches offer economic advantages through efficient injection molding processes that create complex geometries in a single step, eliminating secondary operations required for metal components. Integrated features like living hinges and snap-fits reduce part counts and assembly time, while lighter weight cuts shipping costs and eliminating metal finishing processes reduces environmental compliance expenses.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.