What is Rotary Latch?

Rotary latches, which are important devices, are used in many different industries, like automotive manufacturing and also in the design of medical equipment. These mechanical devices, known as fastening devices, serve the purpose of providing secure closure solutions. They have various advantages, such as being efficient in terms of space usage, being easy to operate, and also being reliable. In this article, we will take a look at how these devices work, the different types that exist, the materials that can be used, the applications in which they can be found, and the criteria that one might consider when selecting rotary latches.

Rotary latches, which are important devices, are used in many different industries, like automotive manufacturing and also in the design of medical equipment. These mechanical devices, known as fastening devices, serve the purpose of providing secure closure solutions. They have various advantages, such as being efficient in terms of space usage, being easy to operate, and also being reliable. In this article, we will take a look at how these devices work, the different types that exist, the materials that can be used, the applications in which they can be found, and the criteria that one might consider when selecting rotary latches.

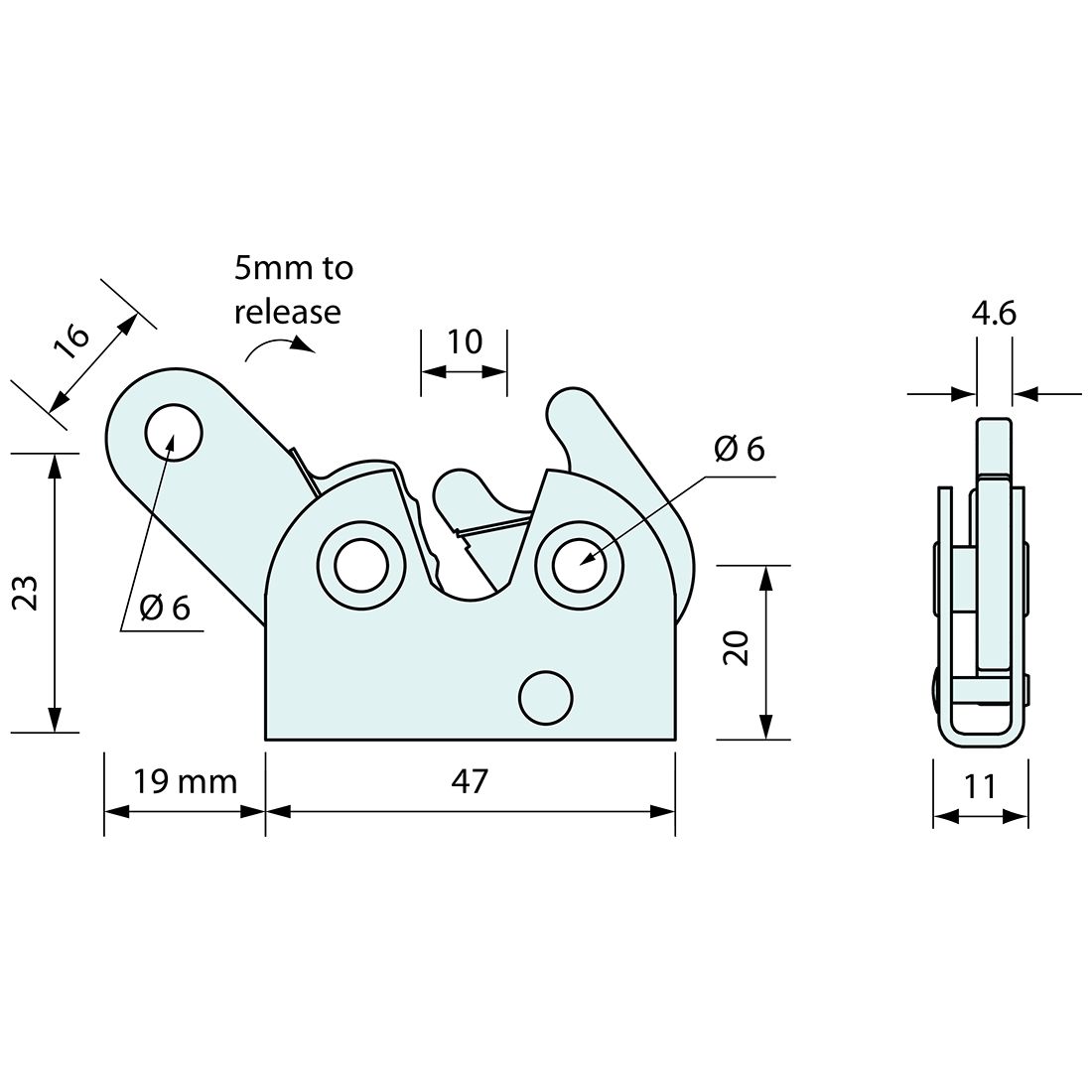

How Does A Rotary Latch Work?

Rotary latches work on a mechanism that is, in a way, both simple and clever, or perhaps you might say ingenious. When something like a striker or a pin enters into the latch, it then engages with a rotating part known as a pawl or catch. This action of rotation creates a secure position, so much so that it prevents the components that are connected from separating or coming apart until there is a deliberate action to release them. This release usually occurs through something like a lever, perhaps a cable, or even an electronic actuator.

Rotary latches work on a mechanism that is, in a way, both simple and clever, or perhaps you might say ingenious. When something like a striker or a pin enters into the latch, it then engages with a rotating part known as a pawl or catch. This action of rotation creates a secure position, so much so that it prevents the components that are connected from separating or coming apart until there is a deliberate action to release them. This release usually occurs through something like a lever, perhaps a cable, or even an electronic actuator.

The rotational movement gives these latches their name and distinguishes them from traditional sliding or hook-type latches. This rotary action provides several advantages, including smoother operation, reduced wear, and the ability to absorb vibration without accidental release.

The movement that goes around, which is often called rotational movement, is what gives these kinds of latches their special name. This sets them apart from the more traditional types of latches that slide or use hooks, which are different in their own ways. This rotary action brings along with it several advantages. For instance, it allows for smoother operation, which is nice, and it also tends to reduce wear and tear over time. Furthermore, it can absorb vibrations without causing any accidental release, which is a concern for many users.

Most rotary latches often have a mechanism that is loaded with a spring, which means it has this thing that pushes back. This mechanism helps to keep the pawl, which is a part of the latch, in a position where it can engage, or catch, the striker. This engagement ensures that the latch stays locked until someone decides to release it on purpose. This quite interesting design creates a mechanical advantage, which simply means it makes it easier to use in certain ways. It also includes a feature that is meant to enhance safety, especially in situations where safety is a big deal and should not be taken lightly.

Seven Types of Rotary Latches

Single-Stage Rotary Latches

Single-stage rotary latches represent the most basic design, featuring one engagement position. They provide a straightforward locking mechanism ideal for applications where simplicity and reliability are the primary concerns. These latches offer a single secure position and they are often found in applications that could be described as light-duty, which means they are not for heavy use but rather for lighter tasks.

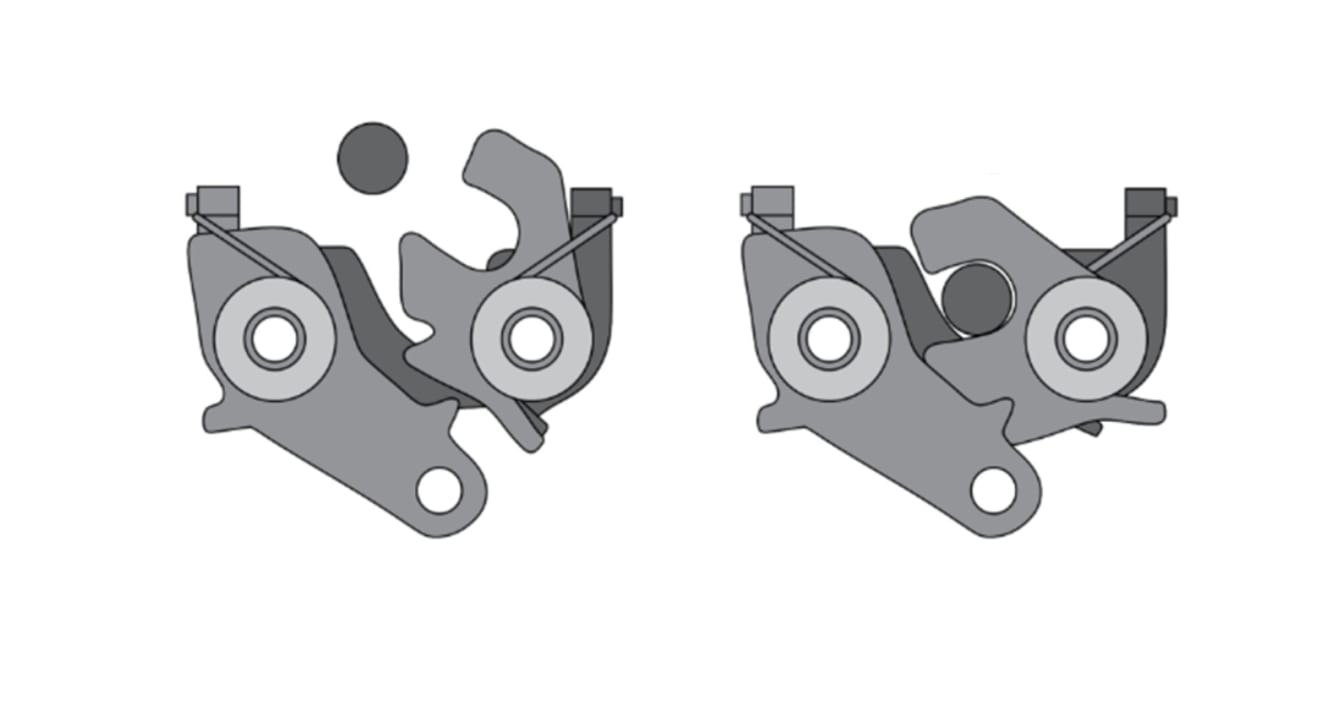

Two-Stage Rotary Latches

Two-stage latches have these positions called primary and secondary engagement positions. This feature provides a kind of enhanced security and also a bit of flexibility, which is rather nice. The initial engagement creates a preliminary connection, while the secondary position ensures maximum security. This dual-stage mechanism proves valuable in applications requiring confirmation of proper closure or preliminary positioning before final securing.

Heavy-Duty Rotary Latches

Specifically designed for applications that are heavy and have a lot of load, these heavy-duty rotary latches come with parts and mechanisms that are reinforced, which are made to handle big forces. These latches often incorporate thicker materials, stronger springs, and more robust pawls to handle intensive use in industrial environments or heavy equipment.

Concealed Rotary Latches

Concealed rotary latches find important use in industrial installations where a flushed, clean exterior, when closed, is important besides assured closure. These latches find their installation beneath the panel or door surface, providing secure, vibration-resistant fastening ideal for access panels, machinery enclosures, and electronic equipment cabinets. Of robust design to give unfailing performance under harsh conditions, and it is also concealed so it does not overtly invite tampering and can be aesthetically integrated.

Adjustable Rotary Latches

These latches mechanisms allow for adjustments, either in tension or in position, which means that they can adapt to different gaps that may be present or the compression needs that might arise. The adjustability makes them ideal for applications where tolerances may change over time or where customized tension settings are necessary.

Electronic Rotary Latches

Incorporating solenoids or motors for remote activation, electronic rotary latches enable integration with security systems, automated processes, or remote access solutions. These sophisticated latches can be controlled through electronic signals, providing advanced functionality for modern applications.

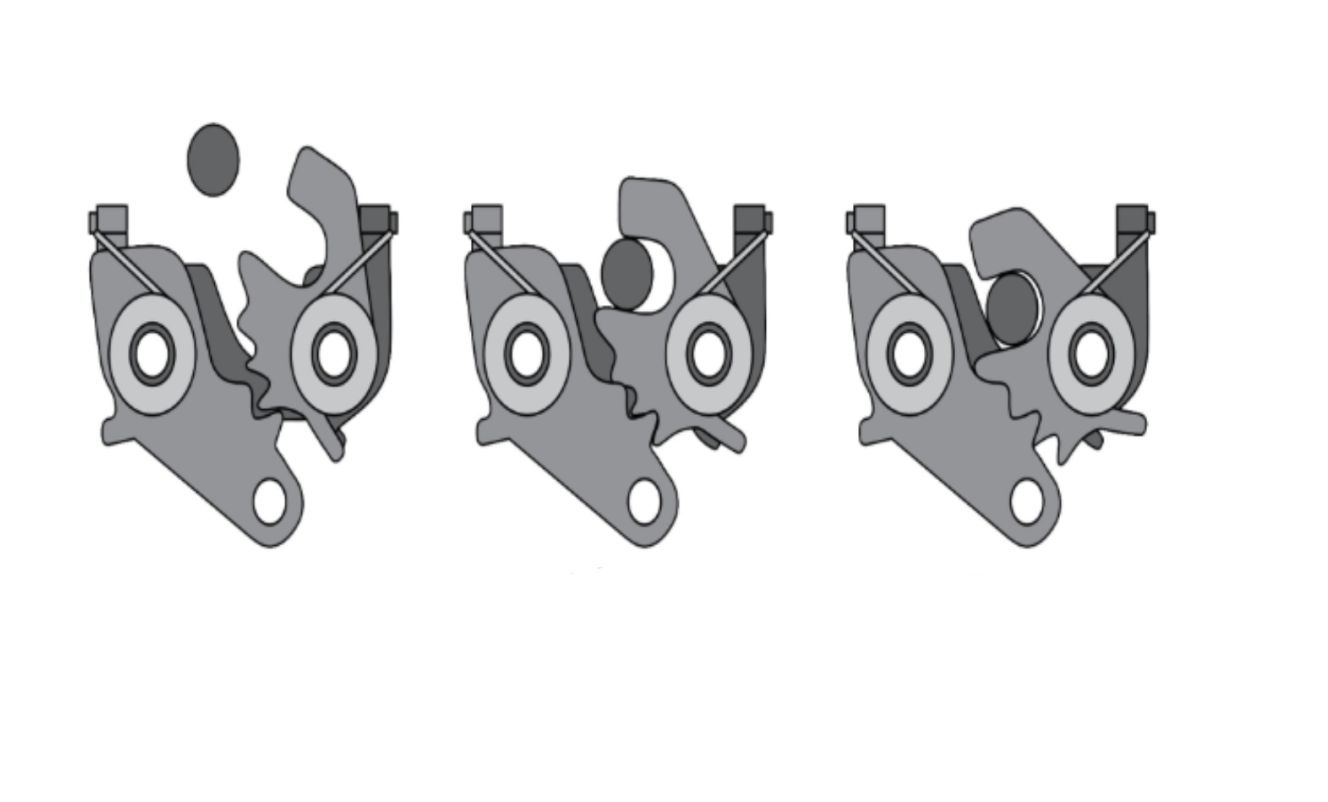

Self-Closing Rotary Latches

Self-closing rotary latches utilize internal spring mechanisms that automatically engage when the striker enters the latch housing. This automatic engagement ensures consistent closure without requiring manual force, making them valuable in safety-critical applications where confirmation of proper latching is essential.

Compression vs. Non-Compression Latches

Compression Rotary Latches

Rotary latches designed for compression unite interconnected parts, forming a secure seal or closing any spaces between surfaces. Their ability to compress renders them perfect for uses needing weatherproofing, minimizing vibrations, or accurate alignment. Compression latches are frequently employed by car doors, exterior gear panels, and HVAC entryways to maintain environmental soundness.

Commonly, the compression mechanism includes a cam mechanism that progressively tightens as the latch activates, pulling the striker and connected part nearer to the latch housing. The mechanical benefit allows for considerable compressive force to be exerted with little input required.

Non-Compression Rotary Latches

Securing components is achieved through non-compression latches, avoiding extra pulling force. These devices ensure dependable connectivity and permit seamless alignment or buoyant motion among elements. Such latches are advantageous in scenarios requiring thermal expansion, the pliability of materials, or deliberate inter-part movement.

Simplified mechanisms in the non-compression design lead to more streamlined setups, decreased manufacturing expenses, and lesser complexity in scenarios where compression is redundant or unwelcome.

Material Considerations: Stainless Steel vs. Zinc Alloy

Stainless Steel Rotary Latches

Rotary latches made of stainless steel provide outstanding resistance to corrosion, along with remarkable durability and strength. Their characteristics render them perfect for use in outdoor settings, oceanic environments, food processing machinery, and medical instruments, where frequent exposure to moisture, chemicals, or stringent cleaning processes is common.

Stainless steel's enhanced tensile strength allows these latches to endure greater loads and more rigorous usage scenarios. Yet, this high-quality material usually incurs greater production expenses and a marginally heavier weight than other options.

Zinc Alloy Rotary Latches

The zinc alloy offers superior shaping, strong resistance to corrosion, and economical manufacturing for rotary latches. The latches provide sufficient functionality for various indoor uses and moderately demanding settings, all at an affordable cost.

Zinc alloy manufacturing employs a die-casting technique that allows for intricate forms and cohesive elements, potentially necessitating various parts in steel structures. The benefit of this manufacturing approach is the facilitation of more efficient designs with reduced components, possibly boosting dependability via simplification.

Security Features: Keyed vs. Non-Keyed Options

Keyed Rotary Latches

Keyed rotary latches incorporate locking mechanisms requiring specific keys for operation. This added security prevents unauthorized access and protects valuable contents or restricted areas. Applications include equipment storage, utility cabinets, and secure compartments where controlled access is essential.

Modern keyed rotary latches may feature sophisticated cylinder designs, master key capabilities, or integration with electronic verification systems for enhanced security protocols. These advanced features make them suitable for high-security environments while maintaining the mechanical reliability of traditional rotary latch designs.

Non-Keyed Rotary Latches

Non-keyed variants prioritize accessibility and convenience for applications where security concerns are minimal. These latches focus on functional performance without the added complexity of locking mechanisms. Common applications include internal compartments, maintenance panels, and general-purpose closures.

While lacking dedicated locking features, many non-keyed rotary latches can be equipped with separate padlock provisions or designed to work in conjunction with external locking systems when security needs evolve.

Key Applications of Rotary Latches

Automotive Trunk Systems

Modern vehicles rely heavily on rotary latches for dependable trunk closure systems. The combination of their small size, superior strength-to-size ratio, and resilience to multiple cycles renders them perfect for applications critical to safety. Rotary latches of automotive quality usually include elements such as resistance to water, mechanisms to prevent vibration, and the ability to release in emergencies.

Medical Equipment Panels

It's essential for medical devices to have secure and reachable panel closures that ensure cleanliness and dependable functioning. In medical settings, rotary latches are typically equipped with antimicrobial substances, sleek surfaces for effortless cleaning, and are designed to fit hands with gloves. The exact features of the engagement guarantee that the panels stay firmly shut while the equipment is being transported or utilized.

Industrial Control Cabinets

Industrial environments require robust closure solutions that withstand harsh conditions while providing appropriate access control. Rotary latches for these applications typically feature heavy-duty construction, environmental sealing capabilities, and options for padlocking or keyed security. Their ability to maintain compression ensures that sensitive electronics remain protected from dust, moisture, and contaminants.

Selection Criteria for Rotary Latches to Consider

Load Capacity

For numerous applications, the key factor is the load capacity, which dictates a latch's ability to securely fasten components under anticipated forces. When choosing suitable rotary latches, engineers are required to assess static load (constant force in standard functioning) and dynamic load (abrupt forces during collision or motion).

Environmental Corrosion Resistance

Exposure to the environment markedly influences the efficiency and durability of latches. Lattches with suitable corrosion resistance are essential for applications dealing with external environments, chemicals, salt sprays, or regular cleaning. Choosing materials, applying protective layers, and opting for sealed patterns all play a role in enhancing environmental resilience.

Safety Rating

Applications crucial for safety necessitate latches that possess the necessary certifications and performance verifications. Sectors such as the automotive, aerospace, and medical equipment sectors maintain distinct regulations for latch functionality in emergencies. Rotary latches with appropriate ratings guarantee adherence to regulations and offer assurance of safety in operations.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.