Get a Quote for Series 31 Cam Lock | Fornd Industrial Solutions

Every cabinet, enclosure, or access panel starts with a small but crucial question — how do you keep it closed securely without making it a hassle to open? In industrial settings, that answer often comes down to one thing: the cam lock. It’s the part that decides whether a control box stays sealed in a dust storm or a maintenance door rattles loose during vibration.

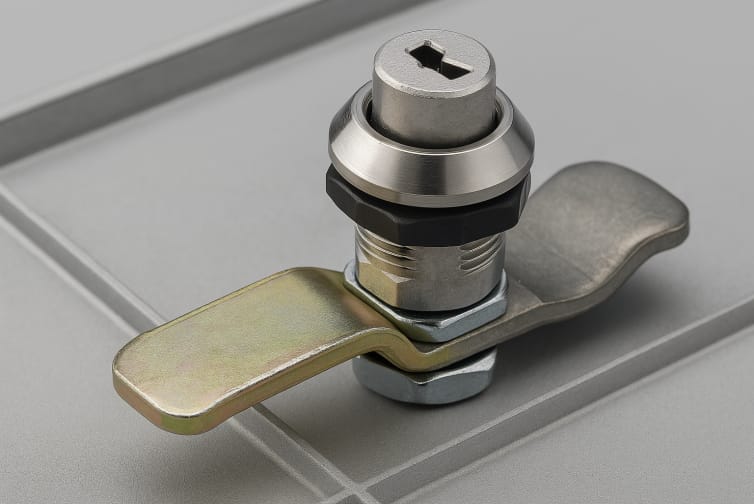

Fornd’s Series 31 Cam Locks take that simple mechanism and refine it for real-world durability — solid zinc-alloy construction, smooth rotation, easy installation, and dependable sealing. These aren’t decorative locks; they’re built for factories, data centers, power stations, and any place where equipment can’t afford to fail.

In this article, we’ll break down what makes the Series 31 stand out: the problems it solves, how it works, what materials give it strength, how secure it really is, how quickly it installs, and why it’s become a trusted industrial standard worldwide.

What Problems Does the Series 31 Cam Lock Solve?

Industrial cabinets live hard lives — constant vibration, heat, moisture, and impatient hands opening and slamming them shut. Ordinary cam locks simply don’t last under that abuse. They loosen, rattle, or seize from dust build-up, forcing operators to keep a screwdriver nearby just to “help it along.”

Fornd’s Series 31 Cam Lock tackles these frustrations head-on. Its compression-fit mechanism keeps panels firmly sealed even when the metal expands under heat or flexes from vibration. The lock’s stainless cam arm resists bending, while the reinforced zinc-alloy body holds its thread tolerance after thousands of rotations.

It also fixes another common pain point: panel creep — when doors start sagging and the seal loses pressure. The Series 31’s design maintains consistent tension, so cabinets in HVAC systems, telecom junction boxes, or transport enclosures stay tight and silent. No more weekly adjustments, no more rattle under load — just dependable closure, cycle after cycle.

How Does the Series 31 Mechanism Work?

Rotational Core

At its heart, the Series 31 uses a 90° or 180° quarter-turn mechanism. The internal zinc-alloy core couples with a cam that swings into a fixed strike plate.

Turning the key retracts or extends that cam—simple motion, zero electronics.

Modular Inserts

The lock accepts multiple insert types: double-bit, triangle, slotted, and hex.

Operators can standardize tool access across facilities, avoiding piles of mismatched keys.

Compression Action

In certain variants, the cam not only turns but compresses, pulling the door tight against the gasket.

That keeps out dust and vibration, a must for machinery and field-mounted enclosures.

What Materials and Finishes Are 31 Cam Locks Used?

Component | Material | Why It Matters |

Housing | Zinc die-cast (ZDC2) | Durable, cost-efficient; resists wear under torque. |

Cam arm | Stainless Steel 304 | Maintains tension and shape under repeated use. |

Cylinder | Nickel-plated brass | Smooth key motion; corrosion-resistant. |

Seal & Washer | NBR / EPDM | Maintains IP65-level sealing. |

Finishes include bright chrome or black powder-coat for visual consistency with control panels. Each lock passes ISO 9227 salt-spray 72 h—no rust, no clouding.

How Secure and Reliable Is 31 Cam Lock?

The Series 31 isn’t trying to impress you with digital tricks—it earns trust the old-fashioned way: by not breaking down. Its strength comes from quiet precision, not noise.

• Tight Tolerances: The key fits snugly, turns cleanly, and doesn’t wobble. That tight fit stops wear from vibration and keeps the mechanism feeling new even after years of daily use.

• Flexible Keying Options: You can order locks that all open with one key, each with its own key, or under a master system—whatever keeps your maintenance team’s pocket lighter.

• Locked-In Cam: A steel circlip keeps the cam arm fixed in place, so even a hard twist or pry won’t pull it out.

• Built to Withstand Torque: The metal body doesn’t strip or deform under pressure; you can tighten panels with confidence.

• Weather-Proofed: From freezing storage rooms to dusty production floors, it keeps turning smoothly between –40 °C and +80 °C. A quick salt-spray test proves it can live outdoors without corroding.

• Sealed Against the Mess: Optional rubber rings and gaskets keep out fine dust and moisture—no crunching, no rust, no jammed latch.

It’s the kind of lock you fit once, then forget about—because it just keeps doing its job.

How Easy Is It to Install or Replace?

Standardized Fitment

Every Series 31 cam lock is designed around a universal 20.1 × 22.5 mm panel cut-out—no custom drilling, no filing corners. Whether it’s a telecom enclosure or an HVAC door, it drops right into existing cutouts used by most global cabinet systems.

Quick Mounting System

A single hex nut secures the lock body from behind, and a snap-on retaining clip makes installation even faster when working with pre-assembled panels. No torque wrench, no alignment jig—just tighten, test, and move on.

Simple Replacement Process

When maintenance calls, removing the old unit takes less than a minute. Pop off the clip, pull the cylinder, and slide in a new one. The cam aligns automatically, so there’s no need to recalibrate the latch position.

OEM-Friendly Design

Because of that ease, many manufacturers pre-design their sheet-metal cabinets to fit the Series 31 footprint. It reduces assembly time, cuts tooling costs, and guarantees serviceability years down the line.

What Variants Are Available in Fornd’s Cam Lock Line?

Fornd doesn’t label a “Series 31” per se—but the brand’s Cam Lock and Cam Latch range covers the same mechanical logic: a rotating cam, compact housing, and adaptable fixing for metal cabinets or enclosures.

Below are several representative Fornd models that show how the family scales from light-duty access panels to industrial control enclosures.

Model | Type / Description | Material & Features | Image | Product Link |

B-1201-030-40 | T-Handle Quarter-Turn Cam Lock | Zinc alloy body, chrome-plated handle, 90° rotation, key-lockable; ideal for control boxes and HVAC cabinets |

| https://fornd.com/product/t-handle-quarter-turn-lock-b-1201-030-40 |

B-1201-130-A1 | Quarter-Turn Cam Lock with T-Handle | Stainless-steel handle and cam; IP65 dust & water protection; corrosion-resistant for outdoor panels |

| https://fornd.com/product/t-handle-quarter-turn-lock-b-1201-130-a1 |

B-1201-040-A1 | Small T-Handle Quarter-Turn Lock | Compact form factor for narrow doors; 90° clockwise rotation; compression-fit design reduces vibration |

| https://fornd.com/product/t-handle-quarter-turn-lock-b-1201-040-a1 |

These models share a few common traits: a 20 mm-standard cut-out, modular cams for various door thicknesses, and finishes that pass 48 h salt-spray testing under ISO 9227.

In other words—they’re the same workhorses you’d expect from any “Series 31”-style cam lock system, just carrying Fornd’s badge and field reliability.

Get an instant quote or bulk order directly from Fornd. Durable, field-tested, and available in multiple configurations. Visit https://fornd.com/ now.

FAQs

1. What panel thickness does Series 31 support?

1 mm – 3 mm standard; optional spacers expand to 5 mm.

2. Can I order keyed-alike sets?

Yes, Fornd supplies master-keyed and keyed-alike configurations for fleet installations.

3. Are compression and quarter-turn types interchangeable?

Yes, they share the same mounting cut-out; swap the cam to match the door style.