Every industrial cabinet, server rack, or control panel has one small but vital question behind it—how do you keep it closed securely without slowing the people who need to get in? That’s exactly what the Series 58 Cam Lock was designed for: mechanical simplicity with industrial endurance. It’s a lock that doesn’t overcomplicate its job. Instead of electronic modules or sensors, it uses precision-machined parts, strong materials, and consistent tension to perform cycle after cycle.

This article breaks down how the Series 58 works, what makes it reliable, how it compares with modern equivalents—and why Fornd’s industrial cam lock range offers the same dependability with global availability and easy integration.

What Is the Core Mechanism Behind Series 58 Cam Lock?

Quarter-Turn Operation

At its heart, Series 58 uses a 90° or 180° quarter-turn motion.

When the key turns, a flat or cranked cam arm swings behind the cabinet frame, locking it in place through simple mechanical interference.

No electronics, no sensors—just clean rotational mechanics that you can feel.

Tubular Key and Pin System

The Series 58 uses a tubular key, not the flat kind you’d find on a desk drawer.

Inside, seven small pins line up in a circle. When the key slides in, each pin drops into place with a quiet click—you can feel it seat before the lock even turns.

That circular layout spreads the load evenly, so the key turns smooth and stays that way after years of use.

A tension spring behind the core keeps pressure steady, so vibration from machines or outdoor panels doesn’t slowly shake the mechanism loose.

It’s the kind of mechanical precision you don’t notice until something cheaper starts to grind.

Square-Shaft Coupling

Inside, the cam connects through a square drive shaft that eliminates slippage and guarantees torque transfer.

Even after thousands of cycles, the shaft alignment stays tight—no free play, no rattling.

Designed for Industrial Uptime

This compact, reliable structure is why Series 58 cam locks are common in control panels, telecom cabinets, and machine housings.

It’s straightforward, durable, and always ready to turn—because in industrial work, simplicity is reliability.

What Variant Options Does Series 58 Offer?

The Series 58 is modular from the ground up — you pick the parts to fit your cabinet, not the other way around.

Option Type | Available Variants | Purpose / Application |

Barrel Lengths | Short (1–5 mm), Medium (6–12 mm), Long (13–20 mm) | Matches different panel or insulation thicknesses. |

Cam Shapes | Flat / Cranked / Adjustable | Adjusts closing depth and gasket compression for a tighter seal. |

Key Systems | Keyed Alike / Keyed Different / Master Key | Let maintenance teams simplify or separate cabinet access. |

Rotation Angles | 90° / 180°, CW or CCW | Fits door swing and hinge direction in varied layouts. |

Accessories | Dust caps / Lock nuts / Sealing washers | Adds protection against moisture, vibration, and debris. |

This modular setup means the Series 58 doesn’t lock you into one layout — it fits the cabinet you already have. Whether it’s an HVAC unit, a telecom enclosure, or an electrical control box, you can pick the right length, cam, and rotation angle to make it work cleanly every time.

Which Materials and Finishes Are Used to Withstand Industrial Stress?

The Series 58 earns its strength from what it’s made of—not just how it looks.

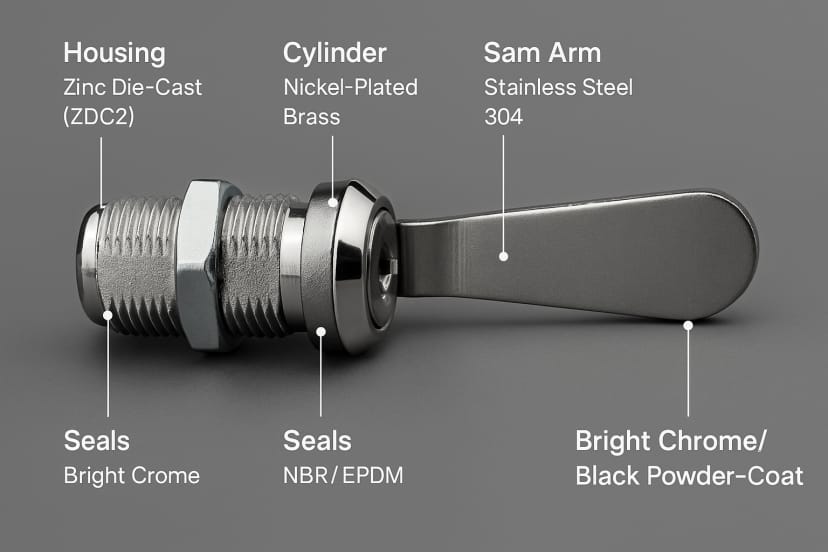

Housing — Zinc Die-Cast (ZDC2)

It’s solid, heavy, and doesn’t mind being handled rough. The threads stay clean even after a few re-installs, and the body doesn’t twist when you tighten it down hard. It’s built for torque, not show.

Cam Arm — Stainless Steel 304

This part takes the most abuse. Stainless 304 keeps its shape, even when doors slam or panels vibrate all day. No bending, no rust streaks later.

Cylinder — Nickel-Plated Brass

The key turns with a clean, tight feel. Brass keeps the movement smooth, and the nickel layer keeps humidity and oil from creeping in. It’s quiet, reliable, and doesn’t chew up keys.

Seals — NBR / EPDM Rubber

A small detail that matters. The seal ring keeps fine dust and moisture out, helping the lock hit IP65 when paired with a gasketed panel. It’s what lets this lock survive in dusty plants and outdoor boxes.

Finish — Bright Chrome / Black Powder-Coat

The last line of defense. Both finishes hold up under heat, salt, and cleaning solvents. Each one passes 72 hours of ISO 9227 salt-spray testing—no pitting, no flaking, no dull film after months of use.

Put together, it’s a lock that doesn’t need coddling. You fit it, you turn it, and years later it still feels solid.

How Resistant Is It to Tampering and Wear?

Security here means mechanical precision, not electronics.

The Series 58 achieves that through details:

• Tight Key Fit: Minimal play stops “feel-picking” and keeps vibration from eroding the pin stack.

• Hardened Insert Core: Resists drilling or torque snapping under stress.

• Stainless Circlip Retention: Keeps the cam arm fixed, even during forced entry attempts.

• Cycle Life: Tested beyond 20,000 open/close operations without performance loss.

• Environmental Endurance: Operates from –40 °C to +80 °C with steady torque.

The outcome: a lock that turns clean, closes solid, and keeps doing so for years—maintenance-free and quietly competent.

How Does the Series 58 Simplify Installation and Integration?

Universal Cut-Out Fit

The Series 58 drops right into standard industrial panel holes — 19×16 mm or 20×22 mm.No custom drilling, no redesign, just a clean fit. It’s the same footprint used in most telecom, HVAC, and machine-control enclosures, which means one part number works across multiple projects.

Mounting Options

You can secure it with a rear hex nut for a firm, permanent fit, or use the snap-on retaining clip when speed matters.Both methods hold tight under vibration, so installers don’t need to over-torque or fine-tune alignment.

Easy Replacement

When a lock wears out, there’s no reason to strip down the whole door.

Pop the clip, pull the core, slide in a new one — that’s it. The cam self-seats, and the latch falls into place on the first turn.It’s a quick swap that takes less time than finding the right wrench.

Built for OEM Consistency

Manufacturers like it because it saves time. Using one lock design across several cabinet lines means fewer panel variations, simpler tooling, and a lighter parts inventory.

In other words — less chaos on the production floor, and faster service in the field.

Why Choose Fornd’s Equivalent to Series 58 Cam Locks?

If you need the same rugged reliability, Fornd’s cam lock line mirrors everything the Series 58 promises—and adds the material precision of modern manufacturing.

Below are top Fornd models built to the same quarter-turn standard:

Product | Image | Key Features | Link |

B-1201-030-40 |

| T-handle cam lock, zinc alloy body, powder coat finish, heavy-duty single-point locking | https://fornd.com/product/t-handle-quarter-turn-lock-b-1201-030-40 |

B-1201-130-A1 |

| Stainless steel cam lock, K333 key locking, brushed & polished finish, robust for outdoor or corrosive environments | https://fornd.com/product/t-handle-quarter-turn-lock-b-1201-130-a1 |

Each model passes ISO 9227 72 h salt-spray, features tight key tolerances, and supports universal panel fitment.

Together, they provide the same mechanical dependability that made Series 58 a benchmark.

FAQs

1. What’s the difference between Series 58 and other quarter-turn locks?

Series 58 uses a heavier cam and tighter cylinder fit. It holds torque better under vibration and lasts longer before showing play.

2. Can I install it without modifying my cabinet?

Yes. It fits standard 19×16 mm or 20×22 mm cut-outs. No extra drilling or brackets needed.

3. How many key combinations are available?

Thousands. You can order keyed-alike, keyed-different, or a master-key system depending on your access plan.

4. Is it weather-resistant for outdoor enclosures?

Yes. With stainless components, rubber seals, and chrome or powder-coat finishes, it easily passes 72-hour salt-spray and IP65 sealing tests.

Order Fornd’s Cam Lock Series today — precision-built for enclosures, telecoms, and automation systems.Explore the full catalog at https://fornd.com

👉 Tell us your cam lock sizes, panel thickness and quantity, and we will propose the right latch solution.

👉 Submit your requirements now and get professional support.

📩 Get a Quote or Request Samples

Let our engineers help you choose the right cam lock.