Types of Cabinet Hinges: A Complete Guide

Smooth and safe access to enclosures across the telecom, energy, automation, and equipment sectors depends critically on cabinet hinges. Correct hinges support frequent access or heavy doors, safeguard wiring or panels, and enhance ergonomics. Offering robust, corrosion-resistant solutions for different mounting styles and door loads, Fornd produces a large range of hinges.

Common Types of Cabinet Hinges

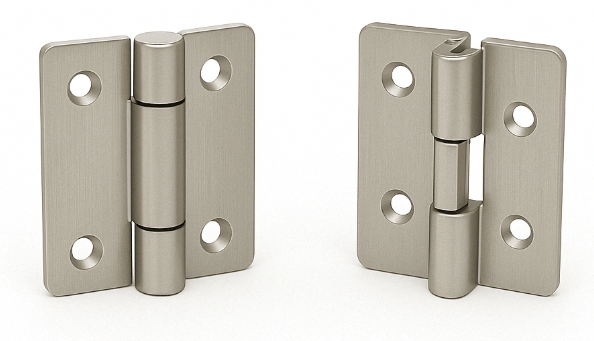

• Butt Hinges

Comprising two plates linked by a central pin, butt hinges are among the most basic forms. They find extensive application on doors and metal or wooden panels. Fornd offers utility box, enclosure, and storage unit industrial-grade versions.

• Detent Hinges

Detent hinges retain the door in fixed open angles and offer controlled movement. Perfect for display tools and access covers requiring consistent alignment. Fornd provides models with preset stops for extra operational safety.

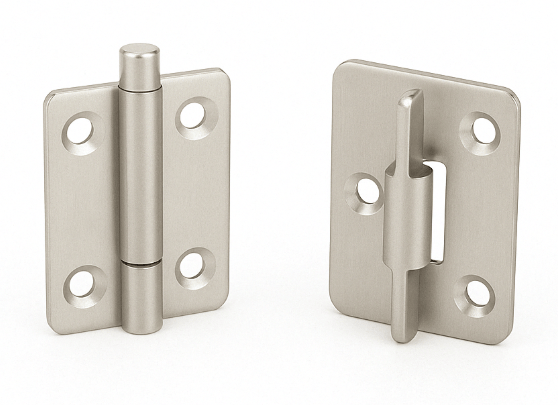

• Offset Hinges

Offset hinges move the door position outward therefore providing complete opening access. Common in enclosures featuring either deep gaskets or frames. Multiple mounting patterns and corrosion-resistant coatings abound in Fornd's offset designs.

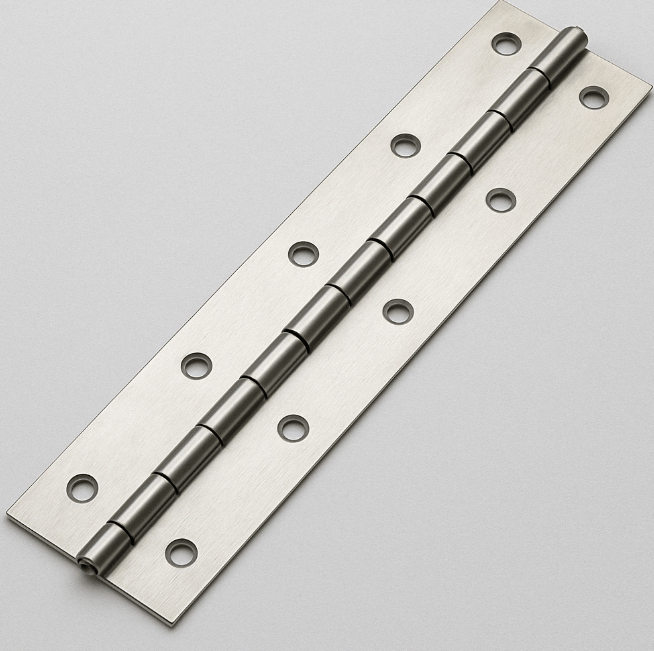

• Piano Hinges

Known also as continuous hinges, these run the whole length of a door or panel. Perfect for long cabinets or lids, they equally distribute weight. Forlong offers long-term durable stainless and zinc-alloy piano hinges.

• Concealed Hinges

Comprising the whole length of a door or panel, these hinges—also known as continuous hinges—cover Long cabinets or lids would benefit from them since they equally distribute weight. Forlong's zinc-alloy and stainless steel piano hinges are robust and long-lasting.

• Lift-Off Hinges (Detachable)

Lift-off hinges let the door be taken off fast without tools. For switchgear cabinets, access panels, and places where internal components call for regular maintenance, they are perfect. Strong pins and simple re-alignment let Fornd create both symmetric and asymmetrical lift-off forms.

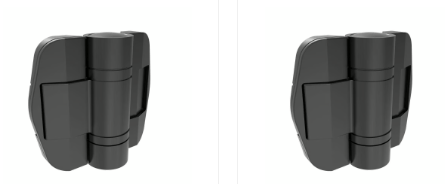

• Torque Hinges

Without additional support, torque hinges hold panels at precise angles. They find application in test equipment lids, adjustable display panels, and inspection covers. In motion-sensitive configurations, Fornd provides models with preset tension that enable steady movement and reduce slamming or accidental closure.

• Heavy-Duty Hinges

These hinges support tall enclosures and either reinforced or large doors in industrial machinery. They resist high cycle use, heavy loads, and impact. For use in outdoor cabinets and large control systems, Fornd's stainless-steel heavy-duty hinges are sold either surface-mounted or welded.

• Surface-Mount Hinges

Surface-mounted hinges are easy to install and perfect for general-use doors. Directly mounted with visible screws, they fit tool chests, storage containers, and equipment boxes. Ford offers flat-mount and right-angle forms using zinc alloy or stainless steel for strength and corrosion protection.

Material and Durability Considerations

Materials fit for industrial use cases define the build-up of cabinet hinges. For outdoor environments including high humidity, stainless steel offers outstanding corrosion resistance. For indoor panels, zinc alloy is both affordable and robust. For low weight or insulated applications, Fornd offers options in reinforced polymers. Surface treatments increase wear resistance and help to ensure a consistent finish by black powder coating or chrome.

Installation & Use Tips

Before mounting, users need to double-check precise hinge location. Clearly mark pilot holes and fastener suitable for your panel material. For outdoor or high-humidity conditions, Fornd recommends stainless steel screws as a tool for corrosion prevention. After installation test swing direction, resistance, and alignment. Lubricate hinges often to maintain smooth motion and slow down wear over time.

How to Choose the Right Hinge

Step 1: Define the type and load of the door.

Stronger doors call for reinforced or heavy-duty hinges. Concealed or lift-off hinges are possible on lightweight panels. Project expected load cycles and environmental pressures.

Step 2: Choose Mounting Style

Choose among surface-mount, flush, or concealed installation. Access frequency, appearance, and space will all affect this decision.

Step 3: Consider Movement Requirements

Torque hinges are best if panels need to hold in place or open only half. Lift-off kinds are more sensible for quick removal.

Step 4: Match the Environment

Outdoor use calls for corrosion-resistant materials. Medical or cleanliness settings call for low-profile, sealed solutions. Fornd offers options for materials and professional advice.

About Fornd

Fornd is a leading handle manufacturer and supplier in China.

We specialize in high-performance, durable locks with rapid production and delivery. Our warehouse holds thousands of standard and custom locks in stock. If you can’t locate what you need, please contact our sales team—we’ll promptly source the right product for your application.

From mechanical latches and hinges to cutting-edge locking handles and electronic access solutions, Fornd produces tough, high-performance locking systems for industrial use We support industries including machinery, energy, transportation, and telecom worldwide. Having decades of engineering experience, Fornd also offers custom development, quick sample delivery, and complete technical support. Whether your application calls for security, vibration, or long-term durability, we can help match the appropriate hinge.

See our selection or ask for a quote at fornd.com.

Welcome to place your order!