What Are Fasteners?

Fasteners are crucially important for the integrity. Their basic elements are used to bind materials together. There are several kinds of fasteners, their materials, surface treatments, and factors to be taken into account while choosing the suitable fastener for certain uses are discussed here. Fornd provides a special variety of industrial fasteners and locking solutions that engineers all around appreciate for their dependability, accuracy, and durability in severe environments.

Types of Fasteners

In industrial environments, fasteners that are designed for precision, safety, and rapid access are designated with an underline. The following specialised categories comprise our current product line:

1. Quarter-Turn Fasteners

These fasteners are utilised in situations that necessitate repeatable fastening or rapid access without the use of a tool. They are specifically designed for speed. They are distinguished by their closed method and application size categorisation:

81 / 82 / 85 Series: Medium-sized stainless or zinc alloy fasteners for telecom racks, cabinets, and industrial enclosures.

D1 Series: Compact models ideal for lightweight panels or access doors.

D4 Series: Used where moderate sealing and repeated operation are needed.

D8 Series: Heavy-duty variants suited for high-vibration environments, offering reinforced holding strength.

Push-to-Close, Turn-to-Open Series (models that are partially supported)

These are ideal for high-cycle or tight installations where efficiency is of the utmost importance. Users can engage the latch by pressing it and release it by turning it.

2.Captive Screws

Captive screws are designed to remain affixed to a panel even when unscrewed, thereby preventing loss during servicing. Fornd offers both Captive Screws and Captive Nuts, as well as assistance with a variety of mounting and actuation requirements:

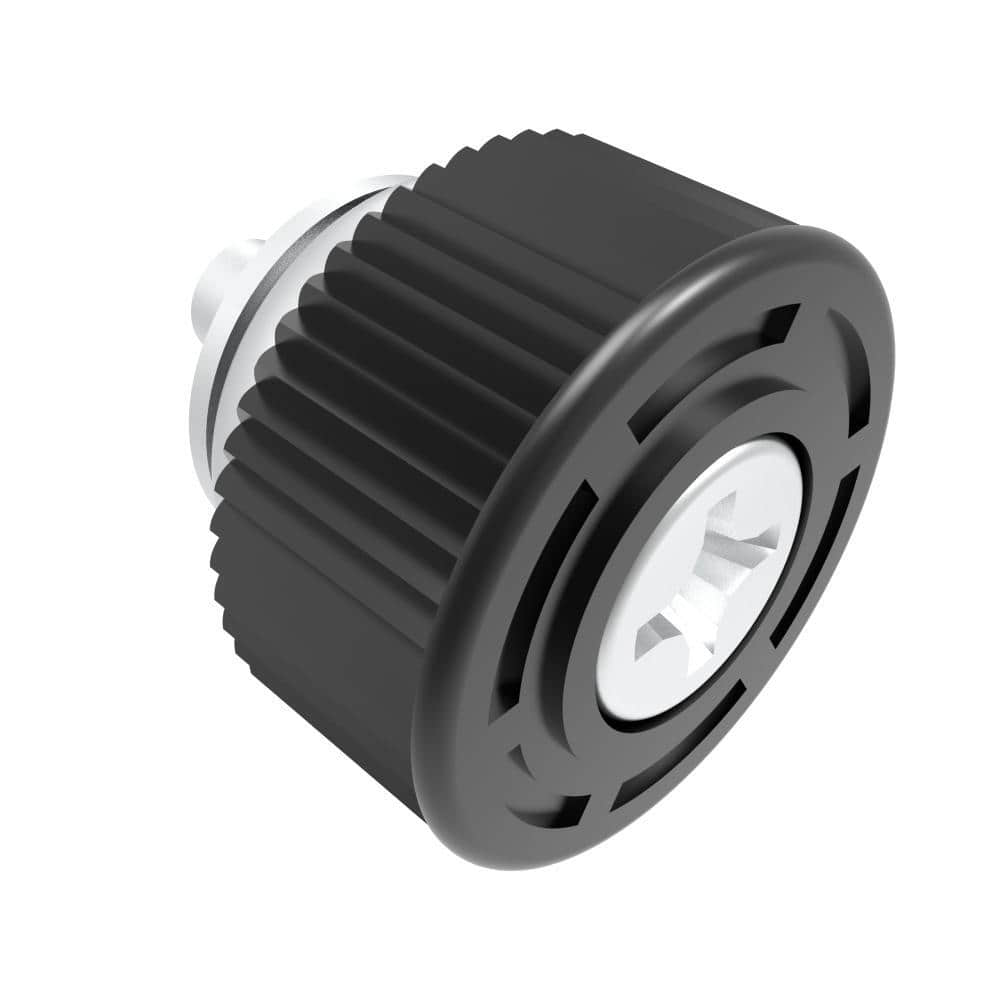

Forms for the Head

The knurled knob head, which is available in black or bright finishes, enables finger operation without the need for a tool.

When manual power or tamper control is necessary, the press-in Phillips recess facilitates screwdriver tightening.

Dual-format heads for field servicing flexibility: Combination Slot / Phillips.

Methods of Mounting

Press-in: Directly insert or snap into metal or plastic panels.

Flare-in: It enhances the stability and grip of sheet metal.

Drawings:

Captive screw with knurled knobs, M3 x 0.5.4C-PS-M4-2F1-K000 is a black dual-drive head with a flare-in type M4 screw.

M3, press-in construction, Phillips recess, black knob.

3. Expansion Bolts

Additionally, Fornd offers mechanical anchors that are suitable for the installation of components into solid substrates, stone, or concrete. Significant holding power is provided by these screws, which are expanding within the hole.

Materials: Zinc-plated steel with a protective chromate coating.

Use Case: For base-mounted enclosures or heavy equipment housings that necessitate high pull-out resistance.

Presently, the size available is D8-316-213-190.

How to Choose the Right Fastener

The lifetime and success of any project depend on the suitable fastener choice. Four main factors will help you to decide:

Understand the Application

Start with assessing the particular needs of your project. The kind of fastener you choose will depend on whether the joint has to be temporary or permanent. Think through the forces the fastener must resist—such as tension, shear, and compression. Evaluate the materials you are joining also to guarantee compatibility and avoid problems including galvanic corrosion.

Evaluate Environmental Conditions

The lifetime and performance of the fastener depend much on the surroundings in which it will function. The integrity of the fastener can be affected by elements including moisture, chemicals, temperature swings, and UV radiation. In marine situations, for example, choosing fasteners with great corrosion resistance helps to stop rust and degradation.

Select the Appropriate Material

Selecting the correct fastener material guarantees fit with the materials being joined and the surroundings. Typical materials are:

• Steel: Strong and durable, steel is suited for most general use.

• Stainless Steel: Perfect for humid or corrosive surroundings, stainless steel boasts outstanding corrosion resistance.

• Brass and Bronze: Often used for decoration, brass and bronze have good corrosion resistance.

• Aluminum: Aluminum is lightweight and corrosion-resistant, so fit for use when weight is a factor.

To stop galvanic corrosion, be sure the fastener material fits the materials being linked.

Determine the Fastener Type

The particular needs of your project will determine which of screws, bolts, nails, or rivets to use:

• Screws: Versatile and offer strong holding power, suitable for materials like wood, metal, and plastic;

• Bolts and Nuts: Ideal for securing heavy components, especially when disassembly may be required;

• Nails: Commonly used in woodworking for their ease of installation;

• Rivets: Provide permanent fastening solutions, often used in metal assemblies.

While choosing the fastener type, take into account the simplicity of installation, necessary holding strength, and if the joint has to be disassembled.

Careful evaluation of these elements will help you choose a fastener guaranteeing the safety, longevity, and strength of your project. Fornd also provides a selection of fasteners,including bolts, screws and so on, meant to satisfy contemporary technical requirements in challenging industrial settings.

About Fornd

Focused on dependable mechanical locking systems and sophisticated hardware for industrial situations, Fornd is a manufacturer. Lock cylinders, fasteners, hinges, latches, handles, and tailored solutions for industries including energy, transportation, telecommunications, and equipment manufacture comprise our product line. Every component is made with consideration for application fit and lifetime. Upon request, we provide technical drawings, expert advice, and free samples. Go to fornd.com to go over your needs or get a price.