In mechanical terms, anything that can join two or more objects is called a fastener. Due to this, the joints they create are not permanent; that is, they can be dismantled without causing any damage to the individual parts that comprise the joint. When it comes to building and manufacturing, fasteners are essential for holding everything together.

Cars, furniture, electronics, and buildings all make use of rapid fasteners. They all have a purpose, regardless of size, shape, or material. Their size can vary greatly, from the tiniest screw in a high-tech electrical equipment to the largest bolts and nuts utilized in the construction of buildings.

Picture a massive, richly woven carpet. The intricate design is made stronger and more beautiful by the fine threads that work together. The fasteners in this tapestry are like the invisible knots and stitches that keep the strands from coming undone. They act like fasteners, binding the threads together into a strong and useful structure, by providing the required tension and connection.

Types of Fasteners

When designing a product, engineers have access to an almost infinite variety of fasteners. Hardware fasteners include things like bolts, screws, nuts, grommets, rivets, and studs. The following are examples of fasteners that you might see using frequently.

Screws

Screws are fasteners with an external thread and an interior thread that are designed to mate with each other. Standard screws are readily misplaced by users when operating. In their fastener assemblies, Soutcho makes use of captive screws. Protect delicate electronics and keep hardware in place with captive screws that stay fastened to a panel. Captive screws stay fixed to the outside panel even after they are undone. The self-aligning float and spring ejection feature of this screw type make installation a breeze. Using threads guarantees a safe connection.

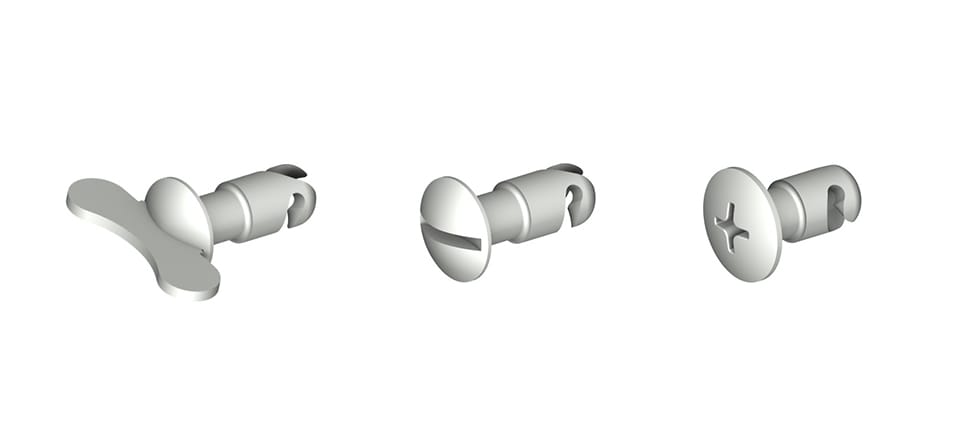

DZUS® Quarter-Turn Fasteners

With the use of fasteners, engineers may make an assembly that is both fast and secure. A simple 90-degree turn allows users to swiftly and simply secure or release the fastener. Strong and consistent clamping force is provided by DZUS fasteners, ensuring that they remain securely fastened even when subjected to vibration. This fastener type remains firmly fastened to the panel, making it easy to use and ensuring that no hardware gets lost.

Quick Access Fasteners

Fasteners with Quick Access make installation and removal a breeze. The fastener will remain attached to the panel at all times, so users won't ever loose it. The fastener offers a constant clamping force and remains firmly fastened regardless of vibration. In addition to reducing installation costs, this fastener type also speeds up service, is resistant to application vibration, and simplifies operation for the end user.

Rivets

A rivet is a type of fastener that has a head and a stem, or tail, on opposite ends. If the surface is clean on the outside, this fastener will form a permanent bond. The tamper-resistant design of Fornd rivets makes them difficult, if not impossible, to drill or drive through. Users don't need any specialized equipment to install drive rivets. For durability and longevity, the rivets are made of materials that are resistant to corrosion, such aluminum and stainless steel.

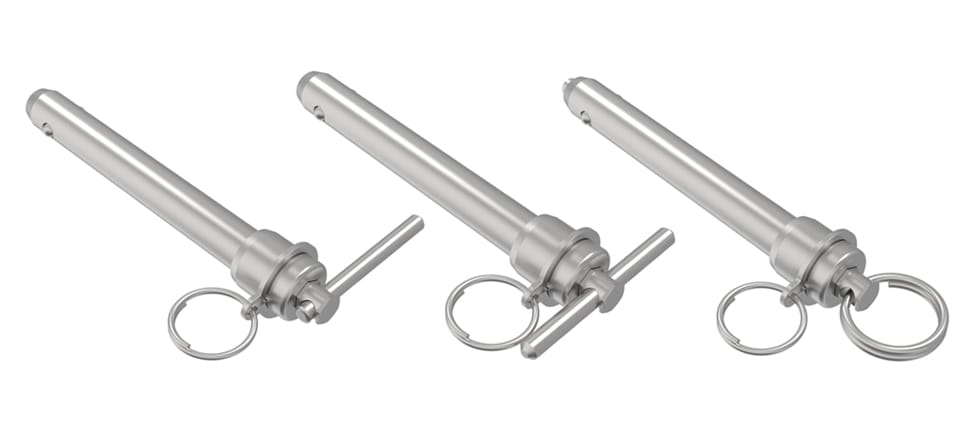

LOCKWELL Quick Release Pins

For uses that call for repeated usage, LOCKWELL quick-release pins offer effortless engagement. Users can secure or release the pin with the push of a button on the quick release pin. These fasteners are designed to be used with a single hand. When you release the button, a spring-loaded internal shaft re-engages the detent balls, ensuring a secure fit.

Material Used For Making Metal Fasteners

Steel, particularly carbon steel, is by far the most popular metal used in the manufacture of fasteners. The material is strong and cheap. The ease of working with steel allows the producer to vary fastener hardness and strength to suit the application through different heat treatments available. One form of protection against environmental conditions is a surface treatment, e.g. zinc or galvanizing. These greatly increase the resistance to corrosion. For very high strengths, alloy steels are the materials for use.

Stainless Steel: When the importance of this quality cannot be overstated, then consideration of stainless steel is a fine place to start. Its ability to resist even extended exposure to moisture, chemicals, and other typically corrosive elements is what makes it ideal for everything from marine work to food processing. Its different grades- 18-8, 316- provide different levels of protection, which allows a near-exact balancing of specific environmental demands.

Aluminum: When weight matters and a compromise is to be made between weight and strength, aluminum fasteners serve the best. They are therefore ideal for the aerospace and automotive industries since, besides being light in nature, aluminum fasteners are very resistant to corrosion. Aluminum alloys can be tailored to provide increased strength and hence find wider application.

Brass: Brass screws provide a decent mix of moderate strength, good corrosion resistance, and excellent electrical conductivity, not to mention their stunning golden appearance- it can be applied in instances where function and beauty are both important. Silicon Bronze: A very good choice for fasteners to be used at marine environments. Very high corrosion resistance, and stronger than regular bronze.

Alloy Steel: Extremely high strength can only be achieved with the application of alloy steel fasteners. Most of the time, heat treatment is done on these fasteners to ensure that they maintain maximum strength in the application condition. Fasteners made of alloy steel often demand coverings since they have lower intrinsic resistance to corrosion.

These materials are cherry-picked by engineers and designers based on what the fastener is supposed to do. Determining the appropriate fastener entails several considerations before it can fulfill what you specifically require in an application. Here are some of the key factors you must consider in selecting a fastener.

How to Choose the Right Fastener for Your Applications?

Material Compatibility

Two main factors should be considered when choosing fasteners: first, the application environment, and second, the material strength. For example, stainless steel is very high in nickel and chromium, so it rusts and corrodes not quickly, so it is typically suitable for use in a corrosive environment. Second, ensure the fastener has a good-enough strength quality for it to survive the intended loads and stresses to be applied. The tensile and shear strengths of the material should be considered because they vary in their capacities among different materials.

Fastener Type

• Self-Clinching Fasteners: These are designed to self-clinch or bite into the material they fasten and thereby provide a secure and vibration-resistant joint. They find wide application in thin sheet metal work.

• Threaded Fasteners: Screws, bolts, and nuts are part of this category, and they are used to thread a connection. These fasteners are selected based on the material being connected, the strength required, and the ease needed to install and remove them.

• Rivets are used for the permanent joining of two or more materials. They come in different materials and sizes and are suitable for diverse applications.

Size and Dimensions

• Length and Diameter: Choose a fastener with the appropriate length and diameter to fit the hole size and thickness of the materials being joined.

• Head Style: The head style of the fastener can affect installation and removal. Common head styles include flat head, round head, and hex head.

Installation Method

• Manual vs. Automated: Consider whether the fastener will be installed manually or using automated equipment. Automated installation often requires fasteners with specific features, such as a thread-locking coating or a reduced head size.

• Tool Compatibility: Ensure that the fastener is compatible with the tools and equipment you have available for installation.

Cost and Availability

• Budget Considerations: Fasteners can vary widely in price, depending on the material, type, and size. Choose a fastener that fits within your budget while still meeting the requirements of your application.

• Availability: Consider the availability of the fastener. Some specialized or custom fasteners may take longer to order and may not be as readily available as standard fasteners.

Application-Specific Requirements

· Vibration Resistance: If the fastener will be subjected to vibration, choose one that is designed to resist loosening, such as a self-locking screw or a rivet with a locking feature.

· Corrosion Resistance: In environments where corrosion is a concern, select a fastener made from corrosion-resistant material, such as stainless steel or coated with a corrosion-inhibiting material.

· Temperature Resistance: Choose a fastener that can withstand the temperature ranges of the application. Some materials may lose strength or become brittle at high or low temperatures.

Compliance and Standards

· Industry Standards: Ensure that the fastener complies with any industry standards or regulations that apply to your application. This may include specific material compositions, sizes, or testing requirements.

· Certifications: Look for fasteners that have been certified to meet specific quality standards, such as ISO or ASTM certifications.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.