What Is a Hinge?

Hinge, as a mechanical device, is a mechanical device that connects two objects and allows relative rotation, with a certain degree of flexibility and durability. By allowing rotary motion, hinges are widely used in construction, industry and automotive. When it comes to hinges, Fornd, as an innovator in precision manufacturing, drives innovation and continuous improvement in hinge technology to provide customers around the world with high-performance, highly reliable connectivity solutions.

Why Use Hinges?

In simple terms, the application of hinges in a variety of scenarios, its most essential significance is to allow things to rotate, such as between the door and the door frame, through the hinge can be switched freely. In addition, the hinges maintain their stability.

Hinges can be adapted to various occasions and used in many places. Also common are factory machines and car doors, hoods and so on. Hinges made of different materials can be selected according to different application environments, such as stainless steel, which is very suitable for wet places. Therefore, the hinge has a high practical value.

What Is the Structure of the hinge?

The hinge is a device with simple structure but large function.

Its structure mainly consists of the following key components:

•Blade: that is, two flat plates, respectively fixed in the stationary and movable parts.

•Pin: Used to connect the blades so that they can rotate.

•Bearings: Reduce friction and make rotation smoother.

•Hole: Cylindrical part of a blade, connected by a pin.

•Fixing hole: Used to install screws or nails to fix hinges.

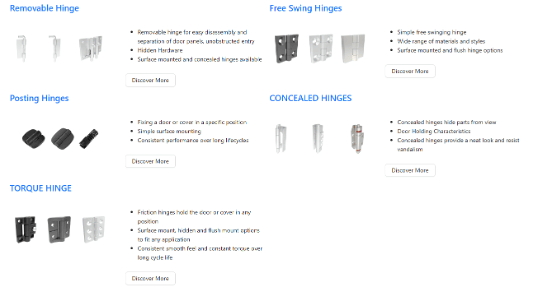

What Types of Hinges Can be Divided into?

The basis for the classification of hinges is varied. Here, it is divided from three dimensions: structural form, functional characteristics and material type. There are great differences in the bearing capacity, application scenarios and design characteristics of hinges under different classification standards.

1. Classification of structure and form

The mechanical structure of the hinge will directly affect its mode of movement and carrying capacity.

•Common hinge: consists of two metal plates connected by hinge pins. It has a simple structure and low cost, and is suitable for light load scenarios. But the disadvantage is the lack of buffer function, frequent opening and closing easy to produce noise and wear.

•Steel ball hinge: The steel ball bearing is embedded in the hinge shaft to reduce resistance through rolling friction, making the opening and closing more smooth. This type of hinge has a strong load-bearing capacity (up to more than 30kg) and high durability.

•Invisible hinge (hidden hinge) : The embedded design is completely hidden inside the door panel when closed, and the appearance looks very simple and no exposed parts.

•Connecting rod hinge: through the multi-connecting rod mechanism to achieve complex movement trajectory, such as parallel movement or Angle adjustment, commonly seen in car seats, industrial equipment inspection doors and other occasions that need multi-direction adjustment.

2. Functional feature classification

According to the special needs of the use scenario, the functional design of the hinge is further subdivided:

•Fixed hinges: Only allow single axis rotation, limit the opening and closing Angle of the door plate (such as 90° or 110°), low cost but limited flexibility.

•Adjustable hinge: equipped with adjusting screws, support up and down, left and right or depth direction fine-tuning, suitable for non-standard installation or deformation of the door panel.

•Self-locking hinges: Automatically lock at a specific angle (such as fully open state) to prevent accidental door closure and improve safety. Typical applications include car door hinges or exterior Windows of high-rise buildings that need to resist strong winds or vibration interference.

•Buffer hinges: In addition to hydraulic buffers, it also includes damping hinges, which provide resistance through springs or silicone pads and control closing speed. This kind of hinge extends the service life, especially suitable for hospitals, nursing homes and other places with high requirements for silence.

3. Material type classification

The hinge material determines its corrosion resistance, strength and applicable environment:

•Stainless steel hinges: containing chromium nickel alloy, resistance to moisture and acid and alkali corrosion, but the cost is higher.

•Steel hinge: carbon steel material by electroplating treatment, high strength, low price.

•Plastic/nylon hinges: Light weight, good insulation, commonly found in electronic products (such as router clamshell) or lightweight storage boxes, but the load-bearing capacity is weak, limited to low-frequency use.

•Aluminum alloy hinges: both lightweight and high strength, excellent oxidation resistance, mainly used in aerospace equipment (such as satellite solar panel deployment mechanism) or high-end automotive parts.

Actual Application Scenario of the Hinge

Thanks to the rapid development of green buildings, industry 4.0 and other fields, the application scenarios of hinges in real life are increasingly diversified.

1. Automotive and transportation

•New energy vehicles: lightweight aluminum alloy hinges are used for doors and charging port covers, taking into account strength and weight reduction needs; Self-locking hinges are used in the folding seats of autonomous vehicles to ensure stability during emergency braking.

•Rail transit: Steel connecting rod hinges can withstand high frequency opening and closing and vibration shocks.

2. Industrial and high-end manufacturing

•Industrial robots: Multi-axis precision hinges support the movement of multiple degrees of freedom of the robot arm, requiring wear resistance and repeated positioning accuracy (±0.01mm), generally used for welding, assembly and other stations.

•Aerospace: The satellite solar panel deployment mechanism uses 3D printed titanium alloy hinges to ensure mission reliability, ultra-light (density 4.5g/cm³), and resistance to extreme temperature differences (-180°C to 200°C).

3. Consumer electronics

•Foldable screen devices: The ultra-thin liquid metal hinge achieves 200,000 fold life through topological optimization, while also avoiding screen creasing issues.

•Smart wear: Micro magnetic hinge for AR glasses leg adjustment, support multi-angle fixation and weight only 1.2g, improve wearing comfort.

4. Customize requirements for special scenarios

•Medical equipment: Surgical instrument doors are made of medical-grade stainless steel hinges with electrolytically polished surfaces to avoid bacterial growth.

How to Choose Hinges?

Choose the right hinge, according to the specific needs and scenarios to decide. You can refer to the following guide:

•The first step is to determine the use case.

Determine the scenario in which the hinge request is used and the specific location.

•Second, consider the material.

Common materials are stainless steel, cold rolled steel, zinc alloy and aluminum alloy, etc... Stainless steel is rust-resistant and durable, best suited for humid environments. The strength of cold-rolled steel is very high. It should be said that it needs additional rust prevention treatment. In contrast, zinc alloys are lightweight. And aluminum alloy, it is characterized by lightweight and corrosion resistance.

•The third step is to determine the load bearing capacity.

•The fourth step is to determine the opening and closing angle.

•The fifth step is to choose the right installation method.

For example, surface mount hinges are fixed directly to the surface, easy to install.

In addition, factors to consider may include the number of hinges, some additional functions carried by the hinge, how corrosion-resistant it is, the degree of appearance and style matching, and so on.

It is also a reminder that it is best to test the smoothness, durability and stability of the hinge before buying.

Choosing the ideal hinge requires a combination of many key factors, including but not limited to opening Angle, material selection, etc. Each application scenario has unique requirements. Whether handling heavy or light loads, or even providing corrosion resistance in harsh environments. The function of the hinge must also match the frequency of use and position control needs of the door, especially in industrial environments.

About Fornd

Fornd has a rich line of cabinet hinges, offering a variety of designs and functions to meet the needs of different application scenarios. Products cover European hidden hinge, semi-hidden hinge, surface mount hinge, wrap hinge, special function hinge and so on.

Featuring a variety of materials, long-lasting durability and a smooth operating experience, hinge products cover the needs of all types from home to commercial space. With a comprehensive range of categories and professional quality, the brand is committed to providing customers with accurately matched hardware accessories to help achieve efficient installation and lasting use. If you have any questions, please visit: https://fornd.com/