A Cam Lock is a mechanical fastening device that uses a rotating component, or in this case, the cam, to secure or fasten objects. Swiveling round to either enter into a strike-plate keep or into an opposing keep, this is done by turning the key. Most commonly used to secure industrial equipment and also used to secure furniture, cam locks can also apply to quick-connect water, electricity, or stage-rigging fittings which allow hoses and cables to be swiftly attached. Usually made from strong materials like brass or steel, cam locks are simple and at the same time useful for the widest possible applications for low-security levels such as general household furniture and for very specialized applications such as in leak-proof couplings. But both have ease of handling and quick locking as the main objectives in the two main classes: the physical security class and the industrial connector class.

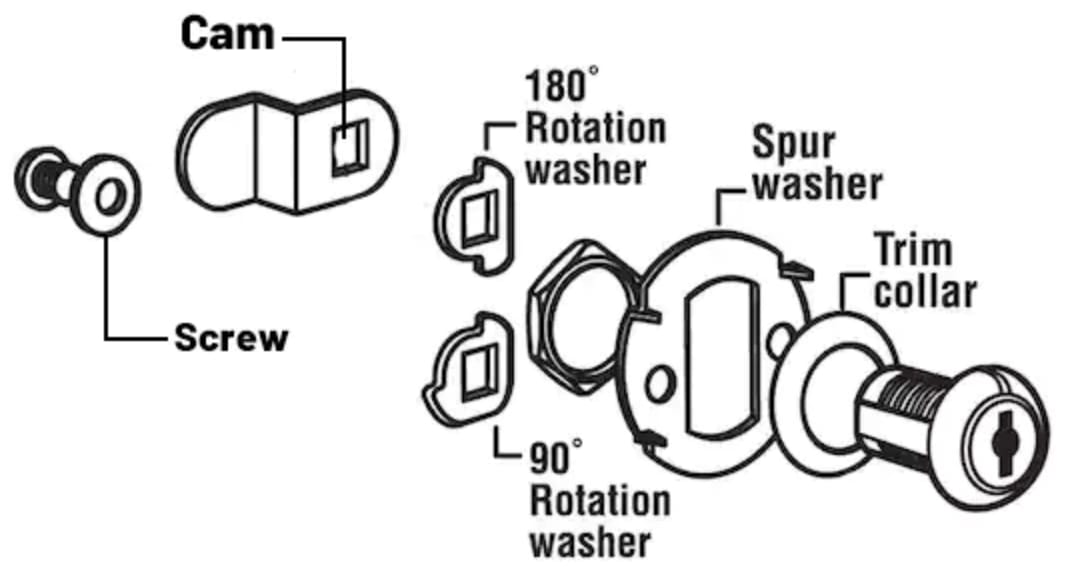

Major Component of a Cam Lock

Major Component of a Cam Lock

Cylinder Housing (or Barrel): This is the main body of the lock that is inserted into the mounting hole. It contains internal mechanisms.

Tumbler Mechanism: This represents the locking core, which partakes in the key and allows the cylinder to twist when an appropriate key is placed inside. Popular variations embody pin systems, wafer systems (disc detainers), and tubular pin layouts.

Keyway: This is the slot where the key is inserted into the cylinder housing. Its shape is specific to the type of tumbler mechanism.

Cam (or Pawl): It is a flat metal piece attached to the rear of the cylinder. As the key is turned, the cylinder will rotate and in turn the cam attached to it. It is the cam which in rotation will engage or disengage the lock working behind a frame or strike plate. Coming in many different shapes and lengths, cams are diversified to fit many applications.

Actuator (Key, Knob, or Lever): This is the part that the user interacts with to operate the lock. Most commonly it's a key, but some cam locks may use a knob, lever, or other tool for operation.

Stop Plate (or Cam Stop): This small component is often located at the back of the cylinder housing and limits the rotation of the cam to a specific angle (e.g., 90 or 180 degrees).

Mounting Nut (or Clip): This is used to secure the cylinder housing firmly to the panel or door where the lock is installed. Nuts are common, but some smaller locks might use a spring clip.

Strike Plate (or Frame): This is the part that the cam engages with when the lock is in the locked position. It's typically a fixed piece attached to the frame of the door, drawer, or enclosure.

How Does A Cam Lock Operates?

A Cam Lock is operated by a metal component that rotates the cam attached to the cylinder. On rotation, by the correct key being inserted and turned, the cylinder causes the cam to swing into either engaging a strike plate or slot (thereby locking the mechanism) or to disengage (unlocking it). It is an application that, in security type applications, physically blocks access, such as cabinets. That is for industrial camlock couplings; rotating the cam will rotate two fittings for a secure seal around hoses or cables. This calls for fine alignment; the key or handle has to be turned to set the angle of the cam for it to be able to fasten or unfasten easily and securely. It is simple, strong (mostly made of brass or steel), and versatile for use in both physical locks and fluid/electrical connections.

Advantages of Cam Locks

Simple Design and Ease of Use

Cam locks have very few parts that move, therefore, they are simple to install and use. A rotating cam either locks or unlocks with a strike plate so no complex tools or expertise is needed. It can be locked or unlocked with a key turn very fast so it is best for everyday use such as cabinets, drawers or lockers.

Versatility Across Applications

Cam locks are versatile mechanical fasteners serving diverse purposes primarily for security in furniture, machinery, and access panels. In addition to security, they serve as rapid leak-proof couplings with cams in plumbing, and agricultural industries for hoses and pipes. This type of diversity allows for use in many different applications, from homes and offices to factories and even stage rigging.

Durability and Longevity

Constructed from robust materials like brass, stainless steel, or zinc alloy, cam locks resist corrosion, wear, and tampering. Industrial-grade variants withstand harsh environments (e.g., extreme temperatures, chemicals), ensuring reliable performance over time.

Quick and Efficient Operation

Cam locks provide quick and efficient operation in both their security and coupling applications. Simple as the locks are, in terms of security locks, they require just a turn of the key to achieve engagement or disengagement. In terms of coupling applications, these types of fittings allow for very rapid tool-free connections, which is very important in the field, especially in firefighting and first aid when quick fluid transfer or quick electrical setup is required.

Customizable Security

Cam locks provide quick and efficient operation in both their security and coupling applications. Simple as the locks are, in terms of security locks, they require just a turn of the key to achieve engagement or disengagement. In terms of coupling applications, these types of fittings allow for very rapid tool-free connections, which is very important in the field, especially in firefighting and first aid when quick fluid transfer or quick electrical setup is required.

Cost-Effectiveness

Cam locks are cheap as compared to the electronic or biometric systems. Being of mechanical design, it automatically reduces long-term costs since it requires no maintenance and power supply.

Leak-Proof and Reliable Seals (Couplings)

A leak-proof and reliable sealing are obtained from camlock fittings which ensure an airtight and pressure connection for liquids or even gases. This becomes very critical in such industries as the chemical process or fuel transfer.

Low Maintenance

Since it has no intricate electronics or fragile components, the cam lock will need only sometimes some oiling or cleaning, thus reducing the downtime and upkeep costs, more particularly in industrial settings.

Types of Cam Locks

Types of Cam Locks

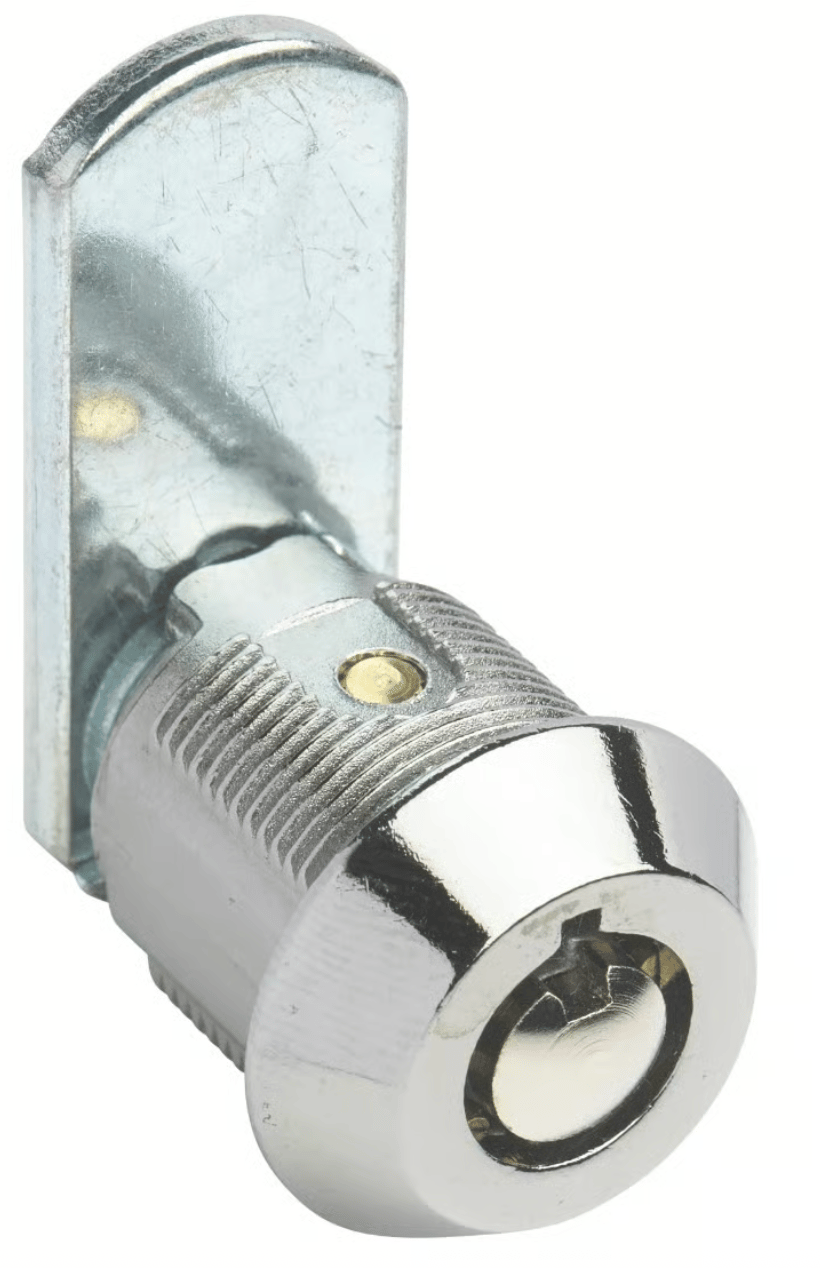

Standard/Cylinder Cam Locks: These are the most common type, featuring a cylindrical housing that is inserted into a mounting hole. A key is used to rotate the internal tumbler, which in turn rotates the attached cam to secure or release the mechanism. They are widely used in cabinets, drawers, and lockers.

Standard/Cylinder Cam Locks

Tubular Cam Locks: These locks use a round key with cuts aligned in a circle. They usually provide a greater level of security than standard cam locks because of their unique keyway and are found commonly in vending machines, arcade games, and some computer equipment.

Tubular Cam Locks

Pin Tumbler Cam Locks: Similar to standard cylinder locks, these use a series of pins that must be aligned correctly by the key to allow rotation. They come in various security levels depending on the number and arrangement of the pins and are a common and reliable choice for many applications.

Disc Detainer Cam Locks (Wafer Tumbler): Like typical pin tumbler locks, there is a set of pins that have to be arranged in a line along the shear line to permit the plug to turn. Differentiating in the varied pin and pin-wafer combinations and quantities these come in many security levels and is͏ a͏nother very popular form of locking mechanism, proven to be very reliable for many applications.

Pin Tumbler Cam Locks

Ratchet Cam Locks: These locks use flat, movable discs (wafers) that have to be lined up by the key. They are usually thought to provide a moderate level of security and are common in furniture, filing cabinets, and some car uses.

Plunger Cam Locks: Like typical pin tumbler locks, there is a set of pins that have to be arranged in a line along the shear line to permit the plug to turn. Differentiating in the varied pin and pin-wafer combinations and quantities these come in many security levels and is͏ a͏nother very popular form of locking mechanism, proven to be very reliable for many applications.

Plunger Cam Locks

Tool-Less Cam Locks (Quarter-Turn/Knob Operated): These locks are designed to be operated without a separate key, often using a built-in handle, knob, or other actuator that can be turned by hand. They are commonly used for quick access and security in electrical enclosures, HVAC systems, and some industrial equipment.

Cam Lock vs. Cam Latch: What’s the Difference?

A cam lock is a type of fastening device that uses a key or other initiating device to rotate the cam, enabling it to hold against a frame or strike plate to provide security as well as to prevent opening. It is meant for applications wherein controlled access to some level of security is required. On the other hand, a cam latch is a simple mechanism used primarily for the quick and easy application of doors, panels, or covers; it does not require a key for locking. Normally, it is operated by a handle, knob, or lever and the cam acquires the frame or the other piece, thus making a reliable closing against accidental opening; however, it does not provide a high level of security as a keyed cam lock.

About Fornd

Fornd, a seasoned manufacturer of industrial cabinet locks and hardware, offers a broad spectrum of solutions for industrial applications. Their product line includes high-quality electronic locks, hinges, handles, and latches, showcasing their deep industry expertise. Discover their comprehensive offerings on the Fornd website: https://fornd.com.