Compression locking plays an important role in cabinets, industrial equipment, and various closed systems. Seemingly simple mechanical device, with safety protection, environmental sealing, easy to operate and other functions. The Ford brand provides users with comprehensive compression latch types, working principles, selection criteria and professional purchasing advice.

What is Compression Latch?

Compression latch, also known as compression door lock. It is a mechanical device that realizes the locking and unlocking function by applying pressure. Using a compression spring or similar mechanism - when the door is closed, the latch is pressed into the lock body, and then automatically ejected to engage the strike plate, thus achieving a locked state. Such a design not only ensures the tightness of the seal, but also effectively isolates external environmental factors such as dust and moisture.

Mainly, there are four common types of compression locks, namely lift compression locks, self-adjusting compression locks, lever compression locks and cylindrical compression locks.

What Are Its Core Advantages?

• Quick Installation & Operation

Compared to traditional locks, they are often designed as plug-and-play systems, reducing installation time and complexity. The operation is also very simple, generally only a basic push and pull action is required to complete the lock and lock.

• High Sealing Performance

In terms of environmental sealing, compression locks block dust and water. For outdoor equipment that requires high cleanliness standards, medical devices or food processing equipment are especially important. By applying constant pressure, the latch ensures close contact between the door panel and the frame, preventing contaminants from entering.

• Vibration & Noise Resistance

In moving vehicles, industrial machinery, or environments with frequent vibrations, traditional locks can come loose, make noise, or even fail. Compression locking effectively reduces such problems by keeping the connection stable with constant pressure.

• Flexible Security Options

Compression locks provide key locking and tool security options that allow configuration according to different security needs. Users have a variety of options, from simple tool operations to highly secure private key systems.

• Intelligent Adaptability

Modern compression latches feature dimension compensation and gasket adjustment to accommodate material and installation tolerances of different thicknesses to ensure optimal performance in a variety of conditions. Multiple actuator and handle options also provide users with greater flexibility and customization possibilities.

The main types of compression blocking and their applications

Lifting and rotating compression latches

It features lifting and rotating the handle to complete the locking and unlocking action. This design provides an intuitive user experience and reliable security.

In the open state, the user first lifts the handle vertically to release the initial pressure, and then turns the handle (usually 90 degrees) to fully unlock it. Closing involves a reverse operation - rotating and then pressing down on the handle, the spring mechanism automatically applies the appropriate pressure to achieve a tight seal.

Typical applications are often found in electrical control cabinets, communication enclosures, medical devices, and automotive parts. When choosing, pay attention to the following:

1. Handle shape: Select according to operation frequency and space limitation

2. Rotation Angle: the standard is 90 degrees; Special applications may require a larger Angle

3. Spring force: Select the appropriate pressure according to the door weight and sealing requirements

4. Material selection: corrosion resistant materials such as stainless steel for outdoor use

Self-adjusting compression blocking

This type of compression lock is mainly used to solve installation tolerances and material deformation problems, so it is particularly suitable for applications where dimensional changes may occur over time.

Self-adjusting compression lock with automatic compensation mechanism, built-in floating structure, can adapt to the size change of ±2mm. In the case of material deformation, the sealing pressure can be kept constant. The original performance is still maintained after long-term use.

It is suitable for scenarios with large temperature changes, such as refrigeration equipment and outdoor cabinets where thermal expansion and contraction occur. It can also be used in composite applications to combine materials with different thermal expansion coefficients. Applied to long-term use of equipment, can achieve the effect of preventing material creep caused by seal failure.

When installing, ensure that there is sufficient adjustment range margin, and check the automatic adjustment function regularly

And with the appropriate sealing strip to achieve the best results.

Lever compression blocking

The lever compression lock embodies the lever principle to amplify the operating force and is suitable for applications requiring greater compression force or limited operating space.

In design features, the leverage ratio is usually 3:1 to 5:1 force amplification. Its low operating profile makes it suitable for highly restricted installations. Its multiple locking points allow simultaneous control of multiple locking positions.

A special variant of the lever compression lock has double lever locks that, for larger door panels, provide a symmetrical pressure distribution. Hidden lever, which is suitable for consumer goods with high aesthetic requirements. There are also power-assist versions, i.e. industrial models with integrated pneumatic or electric assistance.

Application examples are often found in aviation equipment, aircraft doors, equipment maintenance plates. Heavy machinery, equipment enclosures requiring high locking forces, etc.

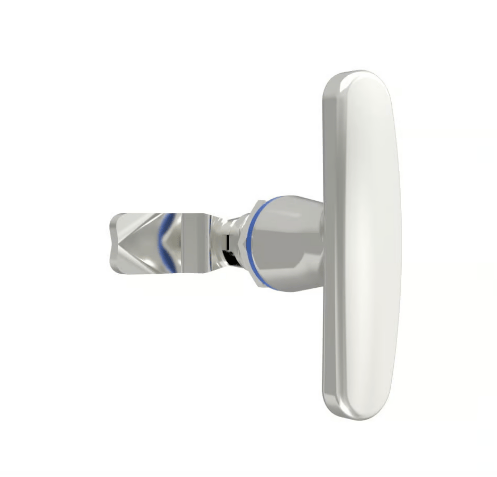

Cylinder compression lock

Cylinder compression lock adopts cylindrical lock core, providing higher safety and clean aesthetics.

The safety features of cylinder compression latching can be summarized in locking core options, with variations ranging from simple to high security. Anti-pick design, this special structure resists physical attack. Key management system, supporting multiple key combination management.

General application industries are military equipment, weapon cases, sensitive device enclosures. Energy sector, substations, power control equipment, etc. There is also transportation, rail transit, marine equipment and so on.

How to choose a compression latch?

Assessment of environmental status

Corrosive environments have special requirements for latch materials. In coastal areas, chemical plants with salt spray or chemicals, 316 stainless steel or special coating products are preferred. Standard 304 stainless steel is the choice for most indoor environments, while aluminum alloy is ideal for weight-sensitive applications with low corrosion risk.

Extreme temperature environments must take into account thermal expansion. Heat resistant plastic or metal parts are required in high temperature areas (such as near the engine); Low temperature environments (such as cold storage) must solve the problem of material brittleness. Therefore, the self-adjusting latch is very suitable for occasions with large temperature fluctuations.

Food processing, medical equipment with high hygiene requirements, requires seamless design and easy-to-clean surfaces. For this, electroplated polished stainless steel or antibacterial coating is a very suitable choice.

Security Requirement Analysis

The security level matches the content value. Standard storage only requires tool operation; Important documents and equipment need to be locked; High-value items require anti-drilling, tamper-proof, high-security lock cores.

Access control requirements are also key. Frequently visited areas are suitable for simple locks; Multi-user devices may require a combination lock or key management system; Automated systems can consider electronic lock options.

Another point that cannot be overlooked is regulatory compliance. Certain industries (e.g., military, medical) have specific lock standards - verifying UL, CE and other product certifications at the time of selection.

Operating frequency and ergonomics

High-frequency operation scenarios (e.g., more than 50 cycles per day) require durable products, with emphasis on: operating force (ideal range of 3-5kgf), handle comfort, and mechanical life (more than 100,000 cycles for quality products).

The strategy of space constraint selection: Low profile design is used for height limitation, and side operation types are considered when the front space is limited. Micro latches are used for small devices.

Precautions for Installation and Maintenance

Panel thickness matching is crucial. Different latch designs are suitable for different thickness ranges (usually 1-5mm); Out of range affects performance. So the product can be adjusted to a wider range.

There are three installation methods. Surface mounting is the simplest, but affects aesthetics. Built-in installation is more beautiful, but requires precision machining. Special brackets are used for certain special purposes.

About Fornd

Among the many compression latch brands, Fornd stands out as an industry leader thanks to its superior quality and innovative design. Ford offers a complete solution - from initial consultation, design phase, production support to after-sales service. Whether you need a standard product for quick delivery or a customized solution for a special application, Fornd's professional team can provide satisfactory service. Visit the official website for customized compression latch solutions that provide reliable protection for your devices.

Select a compression latch based on application scenarios, environmental conditions, security requirements, and operation habits. For demanding applications, Fornd compression latches are undoubtedly a trusted choice to provide long-lasting and reliable performance for your equipment.