A torque hinge uses friction to control the movement of a door, lid, or other type of panel. It allows the panel to be held in any position along its range of motion, without additional hardware or support.

Torque hinges are often used in applications where a panel needs to be held open or closed in a specific position, such as laptop screens, doors on industrial machinery, or medical equipment. They can also be used to prevent a panel from slamming shut, which can be useful in situations where safety is a concern.

Fornd is a factory that specializes in producing friction / torque hinges and supporting personal designs.

What Is a Friction Hinge?

A friction hinge is a specialty hinge that holds a pivoting object in fixed position by providing resistance.

Fornd is a leading provider of high-quality industrial hinges, specializing in solutions that cater to the demanding needs of various industrial sectors. Several Fornd standard friction hinge configurations are shown below that have been developed and fine-tuned over many years. We have chosen the most popular configurations and have organized them into families based on shaft diameter and housing style.

Types of Friction Hinges

There are two types of torque hinge, a constant torque hinge where the torque force is set at the manufacturing stage and remains constant throughout the hinge’s lifespan, and adjustable torque where the end user can adjust the tension on the hinge by means of a screw or other mechanism.

Constant Torque Hinge

Constant torque hinges provide consistent resistance throughout their entire range of motion, allowing for smooth and controlled movement. They are often used in applications where precise positioning is important, such as on medical equipment or laboratory instruments.

Adjustable Torque Hinge

Adjustable hinges allow the user to adjust the level of resistance to movement, typically using a tool-operated adjustment mechanism. They are often used in applications where a panel’s weight may fluctuate during its lifespan, thus changing the torque requirements over time.

How Do Friction Hinges Work?

Friction hinges achieve their function by engineering the specific tolerances between the mechanical components. Additional material such as springs and lubricant are often employed to achieve the desired degree of resistance or damping to the hinge movement.

In some cases, the goal is for the object on the hinge to close completely at a desired degree of speed. In others, the torque is used to hold one or both objects to which the hinges are secured to in a specific position, not necessarily on a fully opened or closed position. When used to hold one of the pivoting members in place, they are designed to be moved by a force of a specific amount of torque greater than its rated torque.

Friction hinges are often customized or custom designed to meet the exact torque requirements of critical applications. Custom designs can provide one-way hinges, in which all the resistance is only in one direction; two-way hinges that have equal damping in both directions, or a combination of both. Design variables include lubricant viscosity, construction material, and degree of space tolerance between components to meet specific applications, such as medical, rugged, high or low temperature, or hazardous environments.

Common Materials Used for Friction Hinges

Friction hinges are available in a variety of materials. The right material for your needs depends on the application requirements. Metal friction hinges may provide the strength needed, or nylon options may be needed for weight conscious applications. Every material has its own set of properties, offering unique benefits.

Zinc friction hinges

Zinc friction hinges provide a cost effective solution with a good balance of strength and design flexibility. For improved visual appearance or chemical resistance, zinc friction hinges can be painted or coated.

Stainless steel friction hinges

Stainless steel friction hinges are strong, durable, and resistant to corrosion and oxidation. Many people turn to stainless steel friction hinges for outdoor use, where there is the possibility of exposure to moisture, salt, UV light and other harsh elements.

Aluminum friction hinges

Aluminum friction hinges are also resistant to corrosion and oxidation, much like stainless steel, but have a much higher strength-to-weight ratio. This makes aluminum friction hinges ideal for reducing weight without sacrificing durability.

Glass-filled nylon friction hinges

Glass-filled nylon friction hinges offer lower cost and greater versatility than metal hinges. These hinges provide an aesthetically pleasing and economical option for applications where weight is important and the strength of metal may not be required. Nylon can be used in traditional hinges, specially designed monitor mounts, and more.

Friction Hinge Features & Benefits

Smooth, consistent feel over hinge lifetime

360-degree shaft rotation–pivot and stay put in any position

All torque hinges meet and exceed life testing to 30,000 cycles

No backlash, Minimal or no spring back

Available in right- or left-hand configurations with additional corrosion protection available

Balanced or Unbalanced Torque available on some models – specify the torque & torque direction required

100% product testing available – min / max and average torque

Ability to mix and match housings & shafts / adapters to fit exact requirements

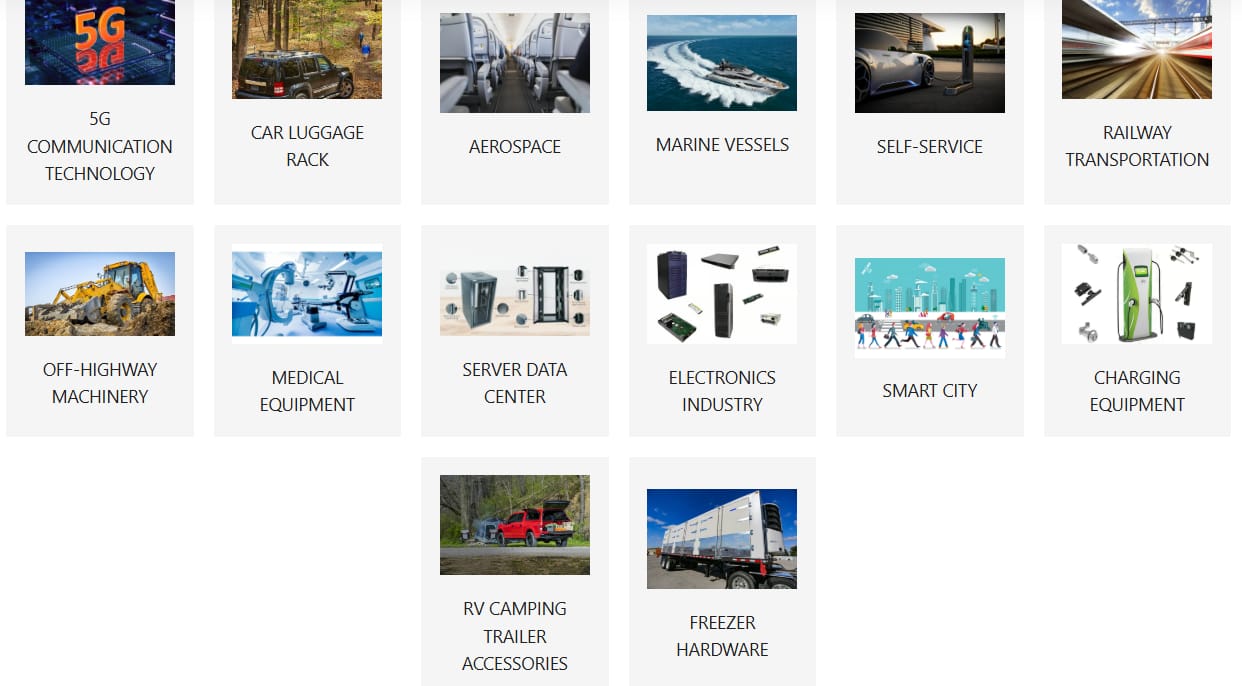

Applications

Friction hinges are used in a variety of applications where resistance is required. One of the most popular applications is a laptop. The hinges allow the laptop screen to remain positioned exactly where you set it. They are also found in electronics devices used for medical, automotive, aerospace and defense. These hinges can be found in many transportation settings including planes, trains, boat and automobiles. Friction hinges are used in many other industrial and consumer applications from kitchen appliances to retail displays.

Choose the Right Friction Hinge

When selecting a friction hinge, consider a multitude of factors — including all the requirements of your application, along with the conditions it will be subjected to. The right torque hinge should keep a panel easy to open and close while keeping it in place when users need it.These considerations include:

Panel Weight

It is important to choose a torque hinge that can support the weight of the panel it is attached to. Specifying load capacity is a key element to ensuring that the hinge has enough torque to perform effectively. Make sure to check the load capacity of the hinge and compare it to the weight of the panel.

Movement Range

Consider the range of motion needed for the panel and choose a torque hinge that can provide the necessary torque across that range. The right torque hinge should keep a panel easy to open and close while keeping it in place when users need it.

Torque Needed

Some torque hinges allow users to adjust the amount of torque they provide, which can be useful for fine-tuning position control. If users could stick something to the outside or inside of your panel, or otherwise change its weight somehow, this feature can keep the torque hinge working as intended regardless of minor weight changes.

Surrounding Environment

Where will the hinge be used? If the device will be exposed to harsh environmental factors such as extreme temperatures, moisture, or salt spray, choose a hinge that is designed to withstand those conditions. Stainless steel hinges resist corrosion, and sealed mechanisms keep the torque engine safe from threats that may come from the surrounding environment.

Mounting

Consider the mounting requirements for the hinge and ensure that it can be easily installed in your application. Whether you need a concealed, surface-mount, countersunk, or barrel-down hinge, assess the application area to find the best hinge to ensure peak performance.

How to calculate the correct torque for a hinge?

The required torque is determined by three main factors:

The mass (weight) of the doorThe size of the door (from the chain to the centre of gravity to the force applied by the user)

The desired tactile feel and the resistance to movement.

The parameter is subjective, so a formula for calculating the required torque (typically force by distance) can only take you so far. It is advisable to add a certain amount of safety factor extra resistance to account for external forces (e.g.: finger pushing a touch screen).

A good rule of thumb is the force on the hinge multiplied by the to the hinge, and increased by about 30% for the “tactile feel”.

Can You Design Your Own Friction Hinge?

At Fornd, it’s easy to connect with engineers to start designing a custom friction hinge. If you are interested in Fornd friction hinges or want exclusive customized products, please visit the Fornd official website to learn more: https://fornd.com.