Compact and featuring strong mechanics are rotating latches. In both industrial and transportation environments, they can guard doors, panels, and covers. Turning a pawl to grab a striker provides firm closing even under vibration or pressure. Fornd offers a large range of rotary latches made for simplicity, accuracy, and strength having decades of expertise in enclosure hardware. This book describes rotary locks, their applications, where they fit, and which Fornd models are ideal for particular design.

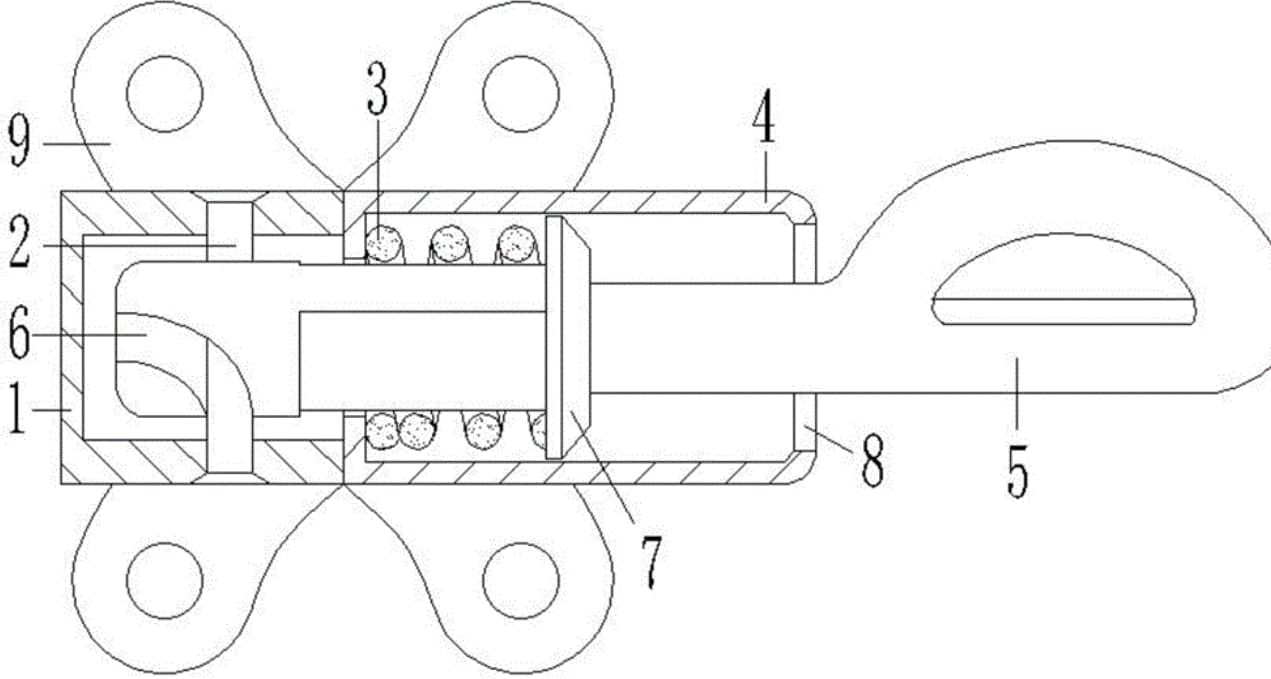

Key Components of a Rotary Latch

A rotary latch is built around a pawl, the rotating piece that catches the striker—usually a strong metal pin fixed to the mating surface. As the door closes, the pawl swings into place, locking the striker securely to resist vibration and force.

These components occupy a house where harmony among all the others is maintained. Usually made of strong, corrosion-resistant materials, the housing guarantees perfect performance even in demanding surroundings. Some models absorb shock and stop rattling with springs or dampers, especially in mobile or highly influential surroundings.

A key advantage in sealed compartments or tight areas is a cable interface, which lets the latch be released remotely.A secondary catch in two-stage designs improves safety by adding an extra step before complete lock-in, so guiding the door into final position.

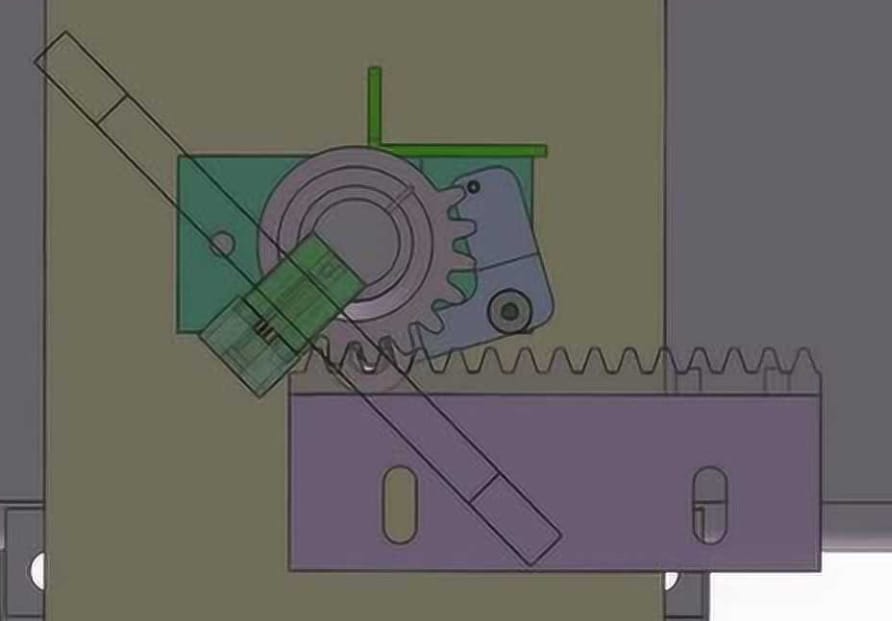

Fornd Rotary Latch Product Types

1. Typical Right-Angle Rotary Latches

With a right-angle cam design locking through a quarter turn, these are Fornd's most often used rotary latches. Used in cabinets, panels, and telecom inclosures, they are available in square, triangular, hex, coin slot drives. Made in stainless steel or zinc alloy, housing sizes run from GH13.5mm to GH26mm, with finishes including polished, powder-coated, or electroplated chrome.

2. Rotation Latches for Hygiene

Designed for clean surroundings, such as medical or food-processing tools, these latches have stainless steel construction and smooth, mirror-polished surfaces. Usually teamed with T- or L-handles for simple operation, they feature water-tight sealing mechanisms.

3. Recessed-headed or tool-operated latches

Often run by special keys (e.g., triangle, hex, or coin-slot), these small models with minimal external projection provide a tamper-resistant solution for limited-access uses.

4. Padlock-Compatible Rotary Latches

Some Fornd models fit safety-critical inclosures by including built-in lock-off features between padlock hasps or wings. In sectors of industry or transportation where several degrees of access control are needed, these are perfect.

5. Customisable Choice

Many Fornd rotary latches support drive head variations, lock cylinder configurations, brushed, anodized surface treatments, optional microswitches for position detection or electronic feedback.

Cable-Release Functionality

Many contemporary applications—especially those involving sealed, multi-point, or remotely accessed enclosures—cable-release mechanisms are not only optional but also absolutely necessary. Pulling a flexible cable linked to the internal actuator of the latch lets users activate the latch from a distance.

Cable operation is particularly beneficial in:

• Vehicle hoods or engine compartments where direct access is limited;

• Multi-point locking systems, where one cable pull can release several latches at once;

• Confined or sealed environments, such as telecom cabinets or battery boxes, where access panels must remain watertight or dustproof.

These cable-compatible setups guarantee general system security and inclosure integrity while yet ensuring simplicity of use.

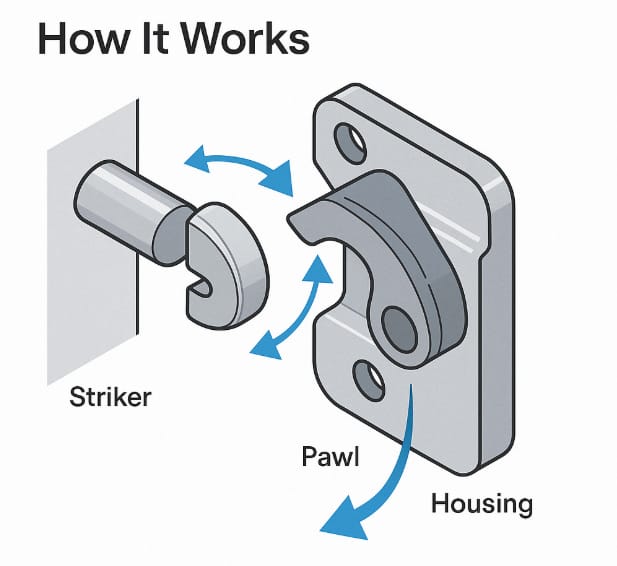

How It Works

A rotary latch pivots a pawl inside its housing to grab a striker pin. The pawl turns and locks into position as the striker approaches to tightly close the door. Some types strengthen hold with dual-stage catches. Many Fornd latches integrate with handles for rapid release or allow cable actuation or integration. Their low maintenance design fits high-cycle, high-vibration environments.

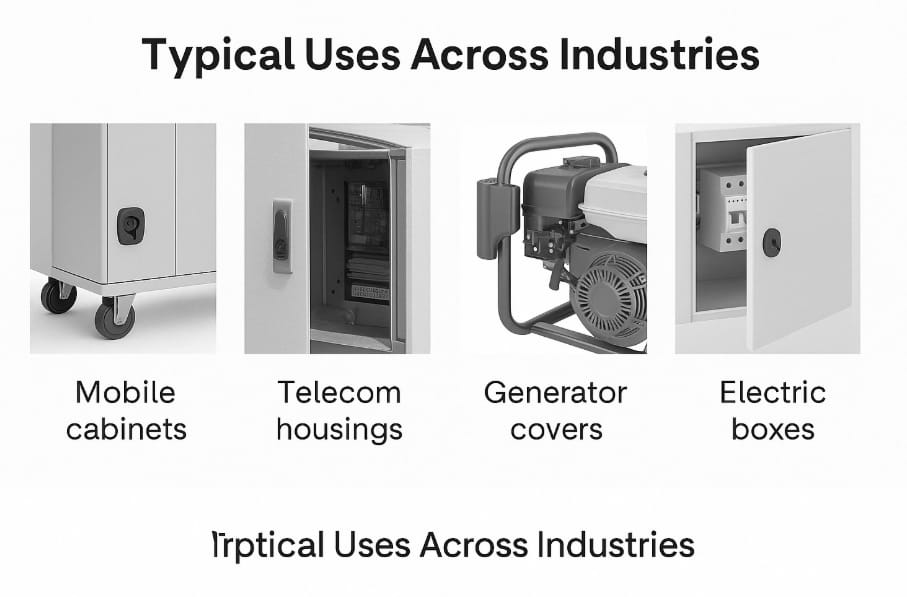

Typical Applications Across Industries

Mobile equipment inclosures, generator and battery housings, rotary latches are found in:

• Telecommunications and electrical cabinets

• Utility boxes and compartmentation for vehicles

Their small size guarantees stable, vibration-resistant performance and lets mounting on thin materials or in confined areas possible.

How to Choose the Right Rotary Latch?

Rotary latches excel when strength and vibration resistance are key—they outperform cam and slam latches in demanding applications like industrial cabinets, vehicle panels, or equipment enclosures, maintaining a secure hold even under continuous pressure.

Decide on the mounting style: surface-mount for easier installation or flush-mount for a sleek, low-profile look. Choose the operation method—handle for simplicity or cable release for remote access.

Environmental factors matter too. For settings with vibration, moisture, or corrosion, opt for a durable latch. Add synthetic locking or tamper resistance if security is critical.

When reliability is essential, rotary latches are the right choice for high-performance applications.

About Fornd

Designed and produced for use in telecom, energy, equipment, and transportation, industrial-grade rotary latches, draw latches, locks, and handles. Our portfolio includes cable-operated, anti-vibration rotary latches in polymer, stainless, and zinc surface-mounted form. Fornd helps engineers everywhere boldly secure their inclues by means of fast sample delivery, expert advice, and custom development. Fornd.com lets you learn more or get a quote.